structure

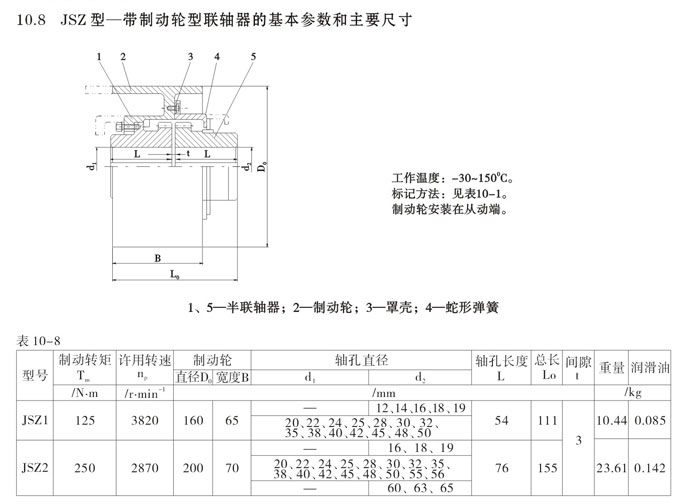

The main structure of the serpentine spring coupling is composed of two half couplings, two half outer covers, two sealing rings and a serpentine spring sheet.It transfers torque by embedding the serpentine spring into the tooth slots of the two coupling halves, and the coupling uses serpentine spring sheets to be embedded in the tooth slots of the two coupling halves to realize the link between the driving shaft and the driven shaft.During operation, the driven end is driven by the axial force of the active end tooth facing the snake spring to transmit torque, which largely avoids the occurrence of resonance phenomenon and the elastic variable generated by the reed when transmitting torque , So that the mechanical system can obtain a better damping effect, with an average damping rate of more than 36%.

特性

1. The coupling is axially embedded in the two halves by a serpentine spring leaf for more than 36%.The serpentine spring leaf of the trapezoidal section is made of high-quality spring steel, subjected to strict heat treatment and special processing, and has good mechanical properties, so that the service life of the coupling is much longer than that of the non-metal elastic element coupling (such as elastic sleeve). Column pins, nylon rod pin couplings) have greatly increased.

2. The tooth surfaces of the two half couplings in contact with the reeds are curved. When the transmission torque increases, the springs will deform along the curved surfaces of the teeth, so that the force points of the two half couplings on the reeds are close .The contact point between the reed and the tooth surface, that is, the change of torque, changes with the size of the transmitted torque, and its transmission characteristics are variable stiffness.Therefore, it has a greater load variation than general elastic couplings.The cushioning effect produced by the transmission force when the reed deforms along the tooth arc, especially when the machine is started or strong impact load, to a certain extent, protects the safety of the supporting parts.

3. The transmission efficiency of the coupling is determined to reach 99.47%, and its short-term overload capacity is twice the rated torque, and the operation is safe and reliable.

4. The aluminum alloy casing protects the spring from being thrown out during operation, and the casing is filled with butter, which not only makes the lubrication good, but also makes the noise when the reeds engage is absorbed by the butter damping and eliminated.

5. The whole machine has few parts, small size and light weight. The spring leaf designed as a trapezoidal cross-section and the trapezoidal tooth groove are particularly convenient and tight, so that the assembly, disassembly and maintenance are easier than ordinary couplings.

6. Since the spring leaf and the tooth arc surface are in point contact, the coupling can obtain greater flexibility.It can be installed to work normally under conditions of radial, angular and axial deviations at the same time.

advantage

1. Good vibration damping and long service life.

2. Large range of bearing variable load and safe starting.

3. High transmission efficiency and reliable operation.

4. Low noise and good lubrication.

5. Simple structure and convenient assembly and disassembly.

6. The whole machine has few parts, small size and light weight.

7. Large installation deviation is allowed.