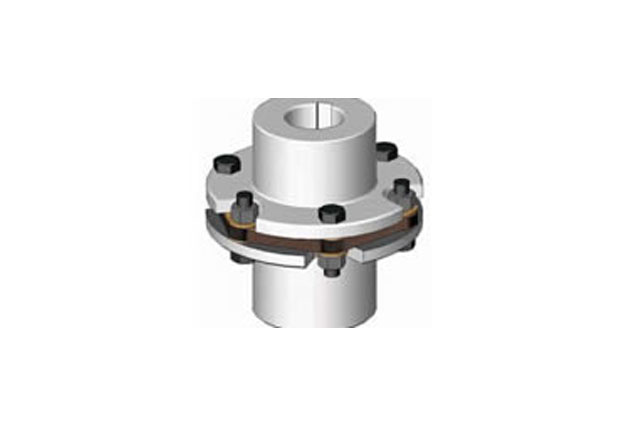

The JZM heavy-duty elastic diaphragm coupling is composed of several groups of diaphragms (stainless steel thin plate) which are alternately connected with two halves of the coupling with bolts. Each group of diaphragms is made up of several pieces, and the diaphragms are divided into connecting rods. And the whole piece of different shapes.

JZM heavy-duty elastic diaphragm coupling has high mechanical strength, large carrying capacity, light weight, small structure size, high transmission efficiency and transmission accuracy, good reliability, convenient assembly and disassembly, and has no relative sliding, no lubrication, and use Long life, no noise, acid, alkali, corrosion resistance, etc., can be used in high temperature, low temperature, oil, water and corrosive medium working conditions, suitable for medium, high speed, large torque shaft transmission, and various The shaft transmission with little change in mechanical device load is extremely versatile.

JZM heavy-duty elastic diaphragm coupling compensates the relative displacement of the two shafts connected by the elastic deformation of the diaphragm. It does not require lubrication, has a compact structure, high strength, long service life, no rotation gap, and is not affected by temperature and oil pollution. Acid-resistant, alkali-resistant, and corrosion-resistant. It is suitable for shafting transmission in high temperature, high speed, and corrosive medium conditions. It is widely used for shafting transmission of various mechanical devices, such as water pumps (especially high-power, chemical pumps) , Fans, compressors, hydraulic machinery, petroleum machinery, printing machinery, textile machinery, chemical machinery, mining machinery, metallurgical machinery, aviation (helicopter), naval high-speed power transmission system, after being dynamically balanced, it is applied to high-speed transmission shaft system Has become more common.

The diaphragm coupling is a mechanical component that connects the driving part and the driven mechanism to rotate together and transfer energy and movement.Couplings can be divided into rigid couplings and elastic couplings. Rigid couplings are usually used in low-speed and heavy-duty situations, and their main function is to transmit larger power; while elastic couplings are mainly used for high-speed rotors. The system uses elastic elements or specific structures to adjust and compensate for misalignment caused by manufacturing, installation and temperature changes. At the same time, general elastic couplings have the function of vibration isolation. In 1982, my country's first high-power, high-speed diaphragm flexible coupling was successfully tested in Southern Power Corporation. This type of coupling has become a hot spot in the domestic engineering community due to its good performance.

The diaphragm coupling has no lubrication, long service life, and greater compensation capability.It transmits torque through flexible steel sheets, and has angular, axial, and radial displacement compensation capabilities and shock absorption.The diaphragm is easy to assemble and disassemble, without lubrication, and can be ideally applied to various working conditions.

Diaphragm couplings are favored by construction machinery and rolling machinery because of their superior performance. Although diaphragm couplings are durable, they can fail or even become scrapped due to various reasons. Therefore, it is of great significance to study the causes of failure.Diaphragm damage is the most important form of coupling failure, a damaged diaphragm ring.The fault tree analysis method is a common and practical system reliability analysis method in engineering. The method is simple, intuitive and flexible, and is suitable for failure analysis of diaphragm couplings.The author will use this analysis method to analyze the failure mechanism of the diaphragm coupling according to the specific failure mode of the diaphragm coupling in the engineering practice.