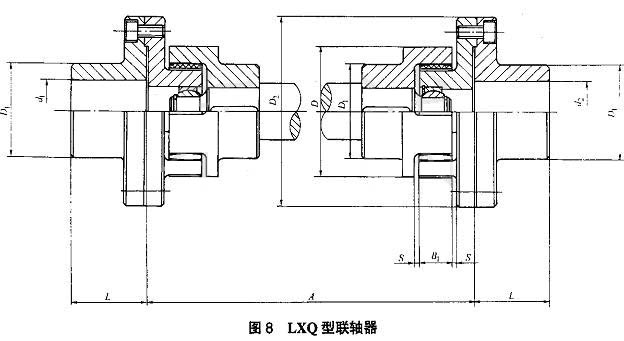

The LXQ ball hinged star-shaped elastic coupling with intermediate shaft is made of engineering plastics as the elastic element. It is suitable for the transmission shaft system connecting two coaxial lines. It has the properties of compensating for the relative deviation of the two shafts, cushioning, shock absorption, and abrasion resistance. Suitable for general occasions, transmission torque 20-35000.NM, working temperature -35-+80 degrees Celsius and interchangeable with German ROTEX coupling, polyurethane elastomer is limited by convex claw blocks, which can avoid internal impact caused by impact Deformation and external deformation caused by centrifugal force.The large concave surface of the protruding claw makes the surface pressure on the involute tooth very small, and the tooth will not wear or deform even if the tooth is overloaded.

The basic parameters and main dimensions of LXQ type intermediate shaft spherical hinge star elastic coupling (JB/T 10466-2004) (unit: mm)

| model | Nominal torque/Nm | Axle hole diameter d1, d2 | Shaft hole length L | D | D1 | D2 | Amin | B1 | S | Mass m/kg | ||

| Y type | J1 type | Amin | Every additional 1m | |||||||||

| LXQ3 | 200 | 10, 11 | 25 | 22 | 65 | 48 | 100 | 160 | 15 | 2.5 | 4.96 | 0.48 |

| 12, 14 | 32 | 27 | ||||||||||

| 16, 18, 19 | 42 | 30 | ||||||||||

| 20, 22, 24 | 52 | 38 | ||||||||||

| 25, 28 | 62 | 44 | ||||||||||

| LXQ4 | 400 | 12, 14 | 32 | 27 | 80 | 66 | 115 | 190 | 18 | 3 | 8.4 | 0.75 |

| 16, 18, 19 | 42 | 30 | ||||||||||

| 20, 22, 24 | 52 | 38 | ||||||||||

| 25, 28 | 62 | 44 | ||||||||||

| 30-32-35 | 82 | 60 | ||||||||||

| LXQ5 | 560 | 14 | 32 | 27 | 95 | 75 | 140 | 215 | 20 | 3 | 21.2 | 0.95 |

| 16, 18, 19 | 42 | 30 | ||||||||||

| 20, 22, 24 | 52 | 38 | ||||||||||

| 25, 28 | 62 | 44 | ||||||||||

| 30-32-35 | 82 | 60 | ||||||||||

| 40, 42 | 112 | 84 | ||||||||||

| LXQ6 | 630 | 16, 18, 19 | 42 | 30 | 105 | 85 | 150 | 235 | 21 | 3.5 | 15.9 | 1.2 |

| 20, 22, 24 | 52 | 38 | ||||||||||

| 25, 28 | 62 | 44 | ||||||||||

| 30-32-35 | 82 | 60 | ||||||||||

| 40-42-45 | 112 | 84 | ||||||||||

| LXQ7 | 800 | 20, 22, 24 | 52 | 38 | 120 | 98 | 175 | 270 | 22 | 4 | 26.5 | 1.7 |

| 25, 28 | 62 | 44 | ||||||||||

| 30-32-35 | 82 | 60 | ||||||||||

| 40, 42, 45, 48, 50, 55 | 112 | 84 | ||||||||||

| LXQ8 | 900 | 22, 24 | 52 | 38 | 135 | 115 | 190 | 305 | 26 | 4.5 | 28.2 | 2.1 |

| 25, 28 | 62 | 44 | ||||||||||

| 30-32-35 | 82 | 60 | ||||||||||

| 40, 42, 45, 48, 50, 55, 56 | 112 | 84 | ||||||||||

| 60, 63, 65 | 142 | 107 | ||||||||||

| LXQ9 | 2000 | 30-32-35 | 82 | 60 | 160 | 135 | 215 | 340 | 30 | 5 | 57.8 | 3.1 |

| 40, 42, 45, 48, 50, 55, 56 | 112 | 84 | ||||||||||

| 60, 63, 65, 70, 71, 75 | 142 | 107 | ||||||||||

| LXQ10 | 5000 | 40, 42, 45, 48, 50, 55, 56 | 112 | 84 | 200 | 160 | 260 | 395 | 34 | 5.5 | 98.2 | 5.6 |

| 60, 63, 65, 70, 71, 75 | 142 | 107 | ||||||||||

| 80, 85, 90 | 172 | 132 | ||||||||||

| LXQ11 | 7100 | 50, 55, 56 | 112 | 84 | 225 | 180 | 285 | 435 | 38 | 6 | 144 | 6 |

| 60, 63, 65, 70, 71, 75 | 142 | 107 | ||||||||||

| 80-85-90 | 172 | 132 | ||||||||||

| 100 | 212 | 167 | ||||||||||

| LXQ12 | 8000 | 60, 63, 65, 70, 71, 75 | 142 | 107 | 255 | 200 | 330 | 475 | 42 | 6.5 | 194 | 6.5 |

| 80-85-90 | 172 | 132 | ||||||||||

| 100, 110 | 212 | 167 | ||||||||||

| LXQ13 | 10000 | 60, 63, 65, 70, 71, 75 | 142 | 107 | 290 | 230 | 370 | 530 | 46 | 7 | 277 | 8.1 |

| 80-85-90 | 172 | 132 | ||||||||||

| 100-110-120 | 212 | 167 | ||||||||||

| LXQ14 | 14000 | 60, 63, 65, 70, 71, 75 | 142 | 107 | 320 | 255 | 410 | 590 | 50 | 7.5 | 338 | 10.3 |

| 80-85-90 | 172 | 132 | ||||||||||

| 100-110-120 | 212 | 167 | ||||||||||

| 130, 140 | 252 | 202 | ||||||||||

| LXQ15 | 20000 | 80-85-90 | 172 | 132 | 370 | 290 | 460 | 675 | 57 | 9 | 645 | 13.6 |

| 100-110-120 | 212 | 167 | ||||||||||

| 130, 140, 150 | 252 | 202 | ||||||||||

| 160 | 302 | 242 | ||||||||||

| LXQ16 | 25000 | 85, 90, 95 | 172 | 132 | 420 | 325 | 520 | 745 | 64 | 10.5 | 769 | 17.5 |

| 100-110-120 | 212 | 167 | ||||||||||

| 130, 140, 150 | 252 | 202 | ||||||||||

| 160, 170, 180 | 302 | 242 | ||||||||||