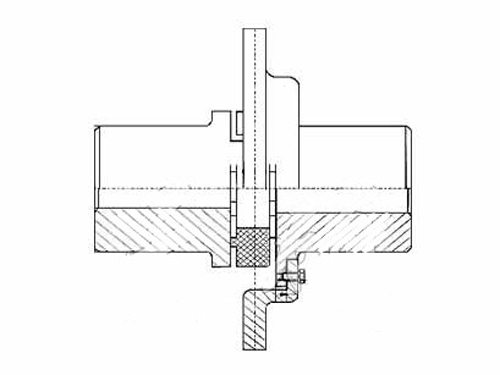

The LXP star-shaped elastic coupling with brake disc is an elastic coupling that uses non-metallic elastic elements to connect. The star-shaped elastic coupling is mainly used to connect two coaxially moving shaft systems, with a certain buffer and The function of vibration reduction is suitable for the installation of all kinds of equipment with braking requirements.

The LXP star-shaped elastic coupling with brake disc is made of engineering plastics as elastic elements. It is suitable for connecting two coaxial transmission shafts. It has compensation for the relative offset of the two shafts, cushioning, shock absorption, and wear resistance. Common occasions, transmission torque 20-35000.NM, working temperature -35-+80 degrees Celsius.The polyurethane elastomer is limited by the convex claw block, which can avoid the internal deformation caused by impact and the external deformation caused by centrifugal force; the large concave surface of the convex claw makes the surface pressure on the involute tooth very small, even if the tooth is overloaded , The teeth will not wear or deform.

The LXP star-shaped elastic coupling with brake disc is made of polyurethane plastic as an elastic element. It has the advantages of cushioning, shock absorption, wear resistance, easy disassembly and assembly, and its working temperature is -35~+80 degrees.It can be interchanged with West German ROTEX coupling.The polyurethane elastomer is limited by the convex claw block, which can avoid the internal deformation caused by impact and the external deformation caused by centrifugal force; the large concave surface of the convex claw makes the surface pressure on the involute tooth very small, even if the tooth is overloaded , The teeth will not wear or deform.

The tooth end of the outer gear sleeve of the LXP brake disc-type star-shaped elastic coupling is in the shape of a horn, so it is not suitable for use under high-speed and impact load conditions, nor for the connection of vertical shafts.When designing the overall structure of the star-shaped elastic coupling, pay full attention to the lubrication and dust prevention between the tooth surface and the roller, as well as the safety protection function.Because if the chain breaks, it may cause a personal accident.The radius of curvature of the drum curve is proportional to the single-sided thinning of the internal teeth, that is, it is related to the meshing gap of the teeth, which makes the assembly and disassembly of the internal and external teeth very convenient.

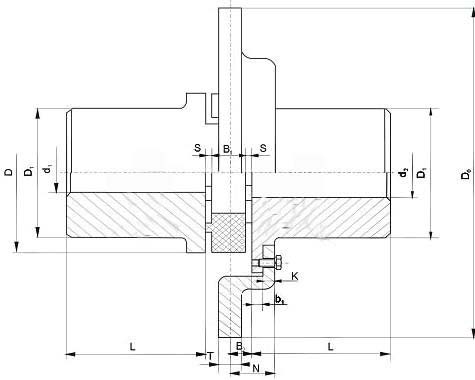

Basic parameters and main dimensions of LXP type star-shaped elastic coupling with brake disc (JB/T 10466-2004) (Unit: mm)

| model | Nominal torque/Nm | Axle hole diameter d1, d2 | Shaft hole length L | D0 | D | D1 | D2 | b1 | B1 | S | Mass m/kg | |

| Y type | J1, Z1 type | |||||||||||

| LXP6 | 630 | 16, 18, 19 | 42 | 30 | 315 355 400 | 105 | 85 | 82 | 11 | 21 | 3.5 | 7.5 |

| 20, 22, 24 | 52 | 38 | ||||||||||

| 25, 28 | 62 | 44 | ||||||||||

| 30-32-35 | 82 | 60 | ||||||||||

| 40-42-45 | 112 | 84 | ||||||||||

| LXP7 | 800 | 20, 22, 24 | 52 | 38 | 315 355 400 450 | 120 | 98 | 95 | 13 | 22 | 4 | 9.3 |

| 25, 28 | 62 | 44 | ||||||||||

| 30-32-35 | 82 | 60 | ||||||||||

| 40, 42, 45, 48, 50, 55 | 112 | 84 | ||||||||||

| LXP8 | 900 | 22, 24 | 52 | 38 | +315 355 400 450 500 XNUMX | 135 | 115 | 110 | 14 | 26 | 4.5 | 15 |

| 25, 28 | 62 | 44 | ||||||||||

| 30-32-35 | 82 | 60 | ||||||||||

| 40, 42, 45, 48, 50, 55, 56 | 112 | 84 | ||||||||||

| 60, 63, 65 | 142 | 107 | ||||||||||

| LXP9 | 2000 | 30-32-35 | 82 | 60 | +355 400 450 500 560 XNUMX | 160 | 135 | 130 | 16 | 30 | 5 | 21.8 |

| 40, 42, 45, 48, 50, 55, 56 | 112 | 84 | ||||||||||

| 60, 63, 65, 70, 71, 75 | 142 | 107 | ||||||||||

| LXP10 | 5000 | 40, 42, 45, 48, 50, 55, 56 | 112 | 84 | +450 500 560 630 710 XNUMX | 200 | 160 | 155 | 19 | 34 | 5.5 | 40 |

| 60, 63, 65, 70, 71, 75 | 142 | 107 | ||||||||||

| 80, 85, 90 | 172 | 132 | ||||||||||

| LXP11 | 7100 | 50, 55, 56 | 112 | 84 | +500 560 630 710 800 XNUMX | 225 | 180 | 175 | 21 | 38 | 6 | 61.8 |

| 60, 63, 65, 70, 71, 75 | 142 | 107 | ||||||||||

| 80-85-90 | 172 | 132 | ||||||||||

| 100 | 212 | 167 | ||||||||||

| LXP12 | 8000 | 60, 63, 65, 70, 71, 75 | 142 | 107 | +560 630 710 800 900 XNUMX | 255 | 200 | 195 | 24 | 42 | 6.5 | 77.8 |

| 80-85-90 | 172 | 132 | ||||||||||

| 100, 110 | 212 | 167 | ||||||||||

| LXP13 | 10000 | 60, 63, 65, 70, 71, 75 | 142 | 107 | +630 710 800 900 1000 XNUMX | 290 | 230 | 225 | 28 | 46 | 7 | 102.6 |

| 80-85-90 | 172 | 132 | ||||||||||

| 100-110-120 | 212 | 167 | ||||||||||

| LXP14 | 14000 | 60, 63, 65, 70, 71, 75 | 142 | 107 | 800 900 1000 | 320 | 255 | 250 | 31 | 50 | 7.5 | 149.5 |

| 80-85-90 | 172 | 132 | ||||||||||

| 100-110-120 | 212 | 167 | ||||||||||

| 130, 140 | 252 | 202 | ||||||||||

| LXP15 | 20000 | 80-85-90 | 172 | 132 | 900 1000 | 370 | 290 | 285 | 35 | 57 | 9 | 228.5 |

| 100-110-120 | 212 | 167 | ||||||||||

| 130, 140, 150 | 252 | 202 | ||||||||||

| 160 | 302 | 242 | ||||||||||

| LXP16 | 25000 | 85, 90, 95 | 172 | 132 | 1000 | 420 | 325 | 320 | 39 | 64 | 10.5 | 298.8 |

| 100-110-120 | 212 | 167 | ||||||||||

| 130, 140, 150 | 252 | 202 | ||||||||||

| 160, 170, 180 | 302 | 242 | ||||||||||