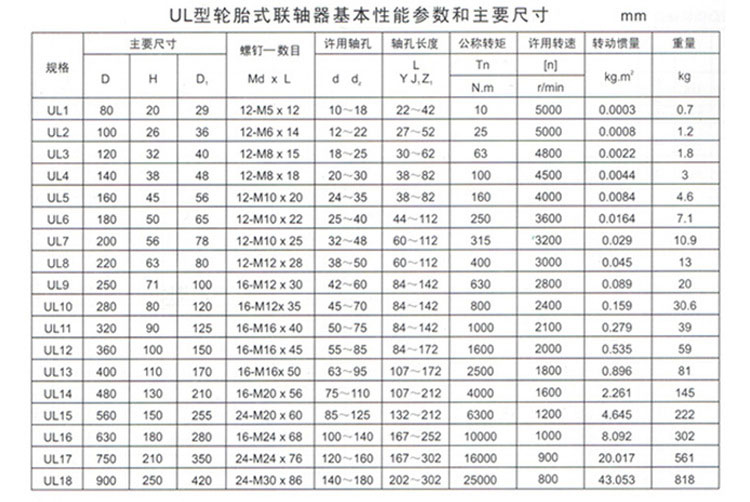

UL tire coupling is a highly elastic coupling, with good shock absorption and excellent performance of offset compensation between shafts, working temperature -20~80 degrees Celsius, transmission torque 10~20000N.M, suitable It is suitable for wet, dusty, shock, vibration, forward and reverse changing and frequent starting working conditions, and it is easy to disassemble and assemble, because the elastic element is an integral tire body, which is convenient for disassembly and maintenance, does not require lubrication, and is durable and reliable. .

The standard half-coupling structure is K type, which can no longer be marked in the display.

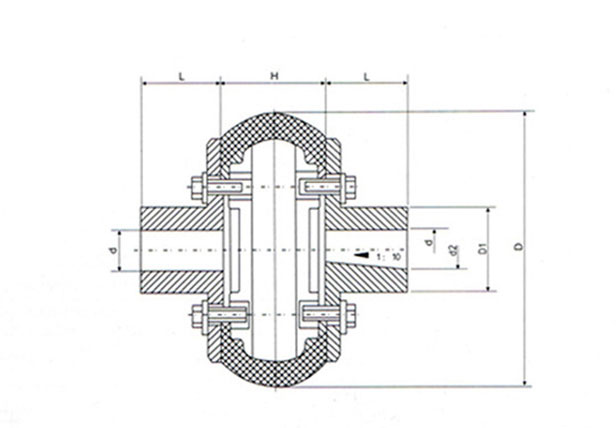

The rubber element (tire body) and the metal pressure plate are vulcanized and bonded together, and the two halves of the coupling are directly connected with bolts during assembly

Flexible, large damping, large compensation

Simple structure, easy assembly, no need to move the coupling axially when changing the tire body

Disadvantages: With the increase of the torsion angle, considerable axial force will be generated on the driving and driven shafts. UL tire coupling is a highly elastic coupling with good shock absorption and superior inter-axis offset Compensation performance, working temperature -20~80 degrees Celsius, transmission torque 10~20000N.M, suitable for humid, dusty, shock, vibration, variable forward and reverse and frequent starting working conditions, and easy to disassemble and assemble , Because the elastic element is an integral tire body, it is convenient to disassemble and repair, does not need lubrication, and is durable and reliable.

The standard half-coupling structure is K type, which can no longer be marked in the display.

The rubber element (tire body) and the metal pressure plate are vulcanized and bonded together, and the two halves of the coupling are directly connected with bolts during assembly

Flexible, large damping, large compensation

Simple structure, easy assembly, no need to move the coupling axially when changing the tire body

Disadvantages: With the increase of the torsion angle, considerable axial force will be generated on the driving and driven shafts