The drum gear coupling is a rigid-flexible coupling. The gear coupling is composed of an internal gear ring with the same number of teeth and a flange half coupling with external teeth.The external teeth are divided into straight teeth and drum teeth. The so-called drum teeth means that the external teeth are made into a spherical surface. The center of the spherical surface is on the gear axis. The tooth side clearance is larger than that of ordinary gears. Allows a larger angular displacement (compared to the straight tooth coupling), which can improve the contact conditions of the teeth, increase the torque transmission capacity, and prolong the service life.The contact state along the tooth width when there is angular displacement.It has the ability to compensate for axis deviation in radial, axial and angular directions. It has the advantages of compact structure, small turning radius, large carrying capacity, high transmission efficiency, low noise and long maintenance cycle. It is especially suitable for low-speed and heavy-duty conditions, such as Metallurgy, mining, lifting and transportation industries, and also suitable for shafting transmission of various machinery such as petroleum, chemical industry, general machinery and so on.

NL type nylon inner gear coupling operating temperature range: -180℃~+160℃(glass fiber rod) FRP solid tent pole glass fiber pipe is made of glass fiber reinforced material and polyester resin pultruded [FRP] glass fiber The rod has excellent performance and characteristics such as long life, light weight, high strength, good flexibility, beautiful appearance, insulation, corrosion resistance, and good comprehensive benefits.

The semi-coupling adopts precision casting, cast HT20-40, cast steel ZG35II, and the shaft hole and keyway are formed by drawing. The inner gear coupling elastomer jacket can be selected from various hardness synthetic rubber and polycarbonate according to user requirements. Urethane glue and reinforced nylon elastomer and other materials.

In order to meet the needs of the new selection of various machinery and the introduction of equipment parts, our factory can provide a complete range of internal tooth-shaped elastic couplings, and can accept non-standard orders according to user needs.

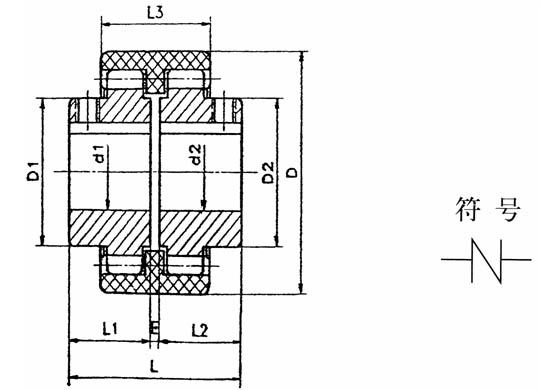

| model | Nominal torque Tn (NM) | Allowable speed n (r/min) | Main size (mm) | Large size deviation | Moment of inertia (KgC m 2) | weight (Kg) | ||||||||

| Diameter of shaft hole d1 d2 | Length of shaft hole | L | D | D1 D2 | E | L3 | Axial (mm) | Radial (mm) | Angle α° | |||||

| NL1 | 40 | 6000 | 6 8 10 | 16 20 25 32 | 37 45 55 69 | 40 | 26 | 4 | 34 | 2 | ± 0.3 | 1 ° | 0.25 | 0.85 |

| 12 14 | ||||||||||||||

| NL2 | 100 | 6000 | 10 12 14 22 | 25 32 42 52 | 57 71 91 111 | 42 | 36 | 4 | 40 | 2 | ± 0.4 | 1 ° | 0.92 | 1.7 |

| 16 18 20 24 | ||||||||||||||

| NL3 | 160 | 6000 | 20 22 24 | 52 62 | 113 133 | 66 | 44 | 4 | 46 | 2 | ± 0.4 | 1 ° | 3.10 | 2.6 |

| 25 28 | ||||||||||||||

| NL4 | 250 | 6000 | 28 30 32 | 62 82 | 129 169 | 83 | 58 | 4 | 48 | 2 | ± 0.4 | 1 ° | 8.69 | 3.6 |

| 35 38 | ||||||||||||||

| NL5 | 315 | 5000 | 32 35 38 | 82 112 | 169 229 | 93 | 68 | 4 | 50 | 3 | ± 0.4 | 2 ° | 14.28 | 5.5 |

| 40 42 | ||||||||||||||

| NL6 | 400 | 5000 | 40 42 45 | 82 112 | 230 | 100 | 68 | 4 | 52 | 3 | ± 0.4 | 2 ° | 18.34 | 6.8 |

| 48 | ||||||||||||||

| NL7 | 630 | 3600 | 45 48 50 | 82 112 | 229 | 115 | 80 | 4 | 60 | 3 | ± 0.6 | 2 ° | 56.5 | 9.8 |

| 55 | ||||||||||||||

| NL8 | 1250 | 3600 | 48 50 55 | 112 142 | 229 289 | 140 | 96 | 4 | 72 | 3 | ± 0.6 | 2 ° | 98.55 | 26.5 |

| 60 63 65 | ||||||||||||||

| NL9 | 2000 | 2000 | 60 63 65 | 142 172 | 295 351 | 175 | 124 | 6 | 93 | 4 | ± 0.7 | 2 ° | 370.5 | 37.6 |

| 70 71 75 80 | ||||||||||||||

| NL10 | 3150 | 1800 | 70 71 75 80 | 142 172 212 | 292 352 432 | 220 | 157 | 8 | 110 | 4 | ± 0.7 | 2 ° | 1156.8 | 55 |