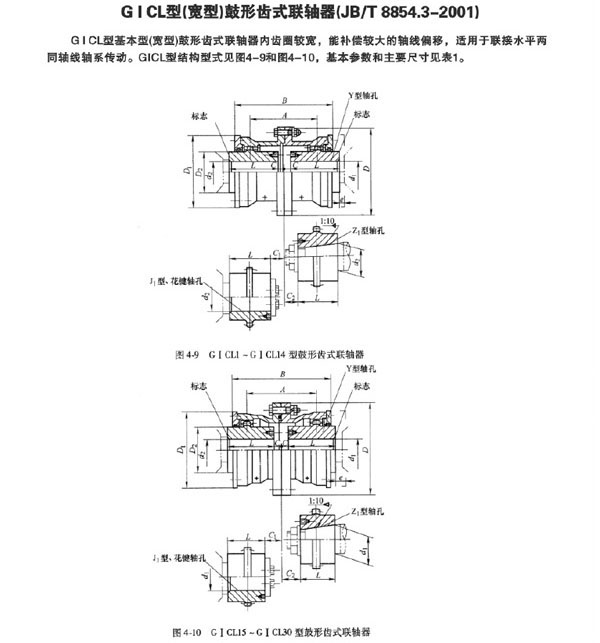

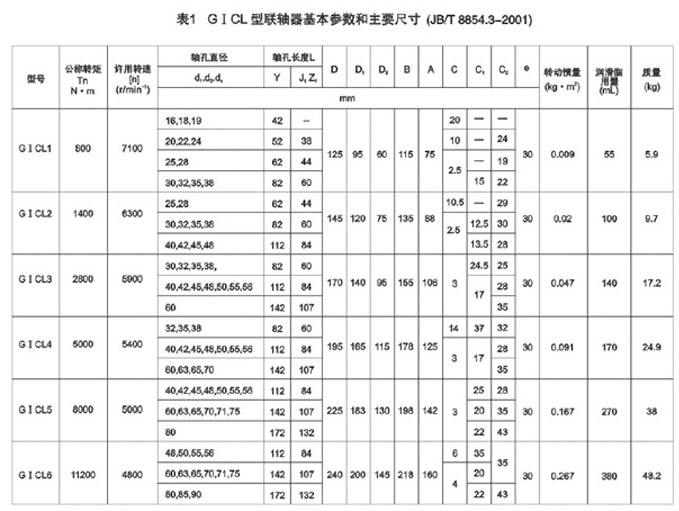

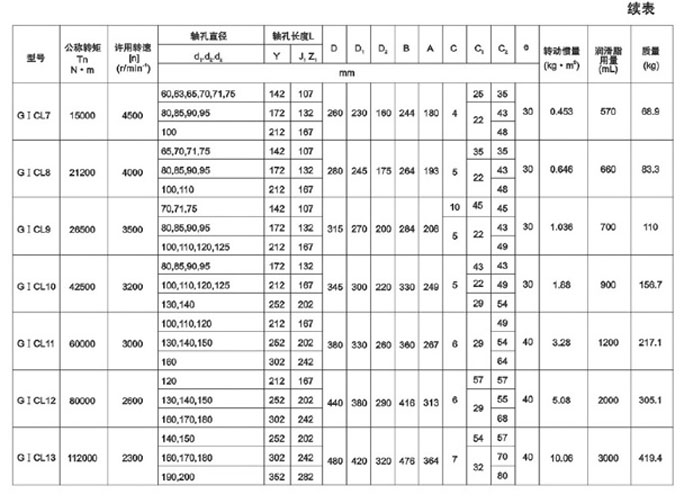

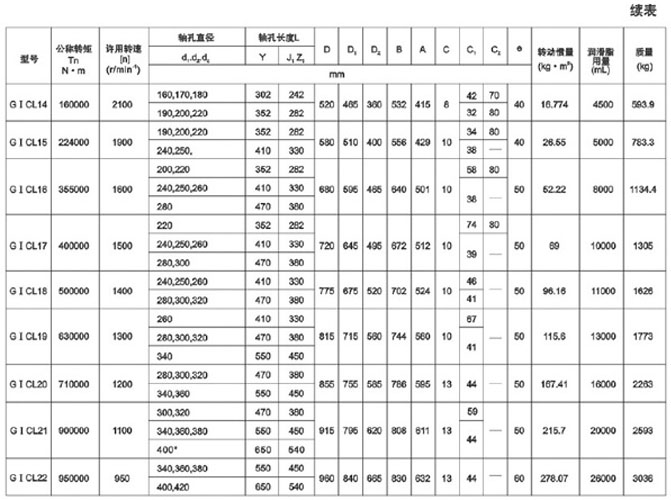

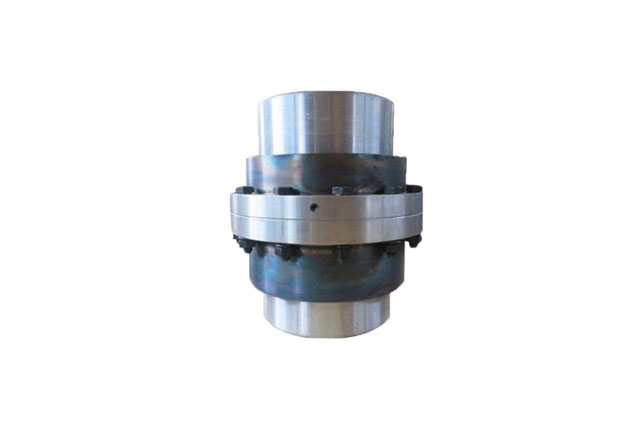

GICL type-drum gear coupling (JB/T 8845.3-2001) is a rigid-flexible coupling. The gear coupling consists of an internal gear ring with the same number of teeth and a flange half coupling with external teeth. And other parts.The external teeth are divided into straight teeth and drum teeth. The so-called drum teeth means that the external teeth are made into a spherical surface. The center of the spherical surface is on the gear axis. The tooth side clearance is larger than that of ordinary gears. Allows a larger angular displacement (compared to the straight tooth coupling), which can improve the contact conditions of the teeth, increase the torque transmission capacity, and prolong the service life.The contact state along the tooth width when there is an angular displacement.It has the ability to compensate for axis deviation in radial, axial and angular directions, and has the advantages of compact structure, small turning radius, large carrying capacity, high transmission efficiency, low noise and long maintenance period. It is especially suitable for low-speed and heavy-duty conditions, such as Metallurgy, mining, lifting and transportation industries, and also suitable for shafting transmission of various machinery such as petroleum, chemical industry, general machinery and so on.