Product Description

Product Description

DO NOT worry about PRICE, we are manufacturer.

DO NOT worry about QUALITY, we have 16 years experience.

DO NOT worry about AFTER-SALES, we are 24 hours online.

Features :

1. The main body is made of high strength aluminum alloy

2. Zero backlash, suitable for forward and reverse rotation

3.Colloid is made of polyurethane, which has good wear resistance

4.Oil resistance and electrical insulation, the middle elasticbody can absorb vibration

5. Compensate radial, angular and axial deviations

6. Removable design for easy installation

7. Tightening method of positioning screw

Suitable for a wide range of devices

CNC lathes Optical inspection equipment

Module slider Servo motor

Company Profile

Certifications

Packaging & Shipping

All products will be well packed with standard export wooden case or

cartons.

Shafts packed with paper tube or plastic bag;

Linear guideways or lead screwswrapped with film or plastic bag;

Guarantee well protected against dampness,moisture, rust and shock.

Our Advantages

FAQ

Q1: Do you have a catalogue? Can you send me the catalogue to have a check of all your products?

A: Yes , We have product catalogue.Please contact us on line or send an Email to sending the catalogue.

Q2: I can’t find the product on your catalogue, can you make this product for me?

A: Our catalogue shows most of our products,but not all.So just let us know what product do you need.

Q3 : Can you make customized products and customized packing?

A: Yes.We made a lot of customized products for our customer before.And we have many moulds for our customers already.About customized packing,we can put your Logo or other info on the packing.There is no problem.Just have to point out that ,it will cause some additional cost.

Q4: Can you provide samples ? Are the samples free ?

A: Yes,we can provide samples.Normally,we provide 1-2pcs free samples for test or quality checking.But you have to pay for the shipping cos.If you need many items, or need more qty for each item,we will charge for the samples.

Any requirements or question,Welcome to “Send” us an e-mail Now!

It’s our great honor to do services for you! You also can get the FREE SAMPLES soon.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Comparison of Helical Couplings with Beam Couplings and Oldham Couplings

Helical couplings, beam couplings, and Oldham couplings are all flexible coupling types used in mechanical systems, but they differ in design and characteristics:

- Helical Couplings: Helical couplings offer high torque transmission, axial flexibility, and some angular misalignment compensation. They are known for their helical-cut grooves that provide flexibility and compensate for misalignment, making them suitable for applications with moderate misalignment.

- Beam Couplings: Beam couplings consist of one or more flexible beams that provide radial flexibility and angular misalignment compensation. They excel in applications requiring high precision and low torque. However, they have limitations in transmitting high torque and axial misalignment.

- Oldham Couplings: Oldham couplings use two hubs and a center disc to transmit torque while accommodating angular misalignment. They offer higher torsional stiffness compared to helical and beam couplings. Oldham couplings are suitable for applications with moderate torque transmission and angular misalignment.

When comparing these coupling types:

- Helical couplings are preferred for applications with moderate torque, axial flexibility, and moderate angular misalignment.

- Beam couplings are chosen for applications requiring precision motion, low torque, and minimal angular misalignment.

- Oldham couplings are used when higher torsional stiffness and moderate angular misalignment compensation are needed.

The choice depends on factors such as torque requirements, misalignment, precision, and the specific needs of the application. Each coupling type offers unique benefits and limitations, allowing engineers to select the most suitable coupling for their machinery systems.

Utilization of Helical Couplings in Mechanical Systems

A helical coupling, also known as a beam coupling, is a type of flexible coupling that is used in mechanical systems to transmit torque and motion between shafts while accommodating misalignment. Here’s how it is utilized:

Helical couplings consist of two hubs, each with helical slots that interlock with the other hub’s slots. The interlocking design allows for flexibility in multiple directions while maintaining torsional rigidity.

When utilized in mechanical systems:

- Misalignment Compensation: Helical couplings can handle angular, axial, and parallel misalignments between shafts. The helical slots provide flexibility, allowing for small amounts of misalignment without transmitting excessive stress to connected components.

- Torque Transmission: Helical couplings transmit torque from one shaft to another while minimizing backlash. The helical slot design distributes torque evenly across the coupling’s surface, ensuring efficient power transmission.

- Reduced Vibration: The helical design of the coupling helps absorb shocks and vibrations, contributing to smoother operation and reduced wear on connected components.

- Compact Design: Helical couplings have a compact and lightweight design, making them suitable for applications with limited space.

- Simple Installation: These couplings are relatively easy to install, with minimal maintenance requirements.

- Various Applications: Helical couplings are commonly used in robotics, motion control systems, CNC machines, and other applications where precision and flexibility are essential.

In summary, helical couplings provide an effective solution for transmitting torque and motion between shafts while accommodating misalignment and reducing vibrations in various mechanical systems.

Specialized Maintenance Routines for Ensuring the Longevity of Helical Couplings

To ensure the longevity of helical couplings, consider implementing specialized maintenance routines:

- Lubrication: Proper lubrication is crucial. Use the recommended lubricant and schedule regular lubrication intervals to prevent friction and wear.

- Cleaning: Regularly clean the coupling to remove dirt, debris, and contaminants that can contribute to wear.

- Inspections: Conduct thorough visual inspections to identify signs of wear, misalignment, or damage. Regular inspections allow you to address issues early.

- Alignment Checks: Periodically check and adjust the alignment of the coupling to prevent premature wear and ensure optimal power transmission.

- Fastener Tightening: Check and tighten fasteners, such as set screws or clamping elements, to prevent loosening during operation.

- Balancing: If the coupling becomes unbalanced, have it balanced to prevent vibrations and reduce wear.

- Temperature Monitoring: Monitor the operating temperature of the coupling area. Abnormal temperature increases can indicate issues.

- Vibration Analysis: Use vibration analysis tools to monitor coupling vibrations and identify any unusual patterns.

- Replacement of Worn Parts: Replace worn or damaged parts promptly with genuine replacement components from the manufacturer.

- Record Keeping: Maintain a detailed maintenance record, including inspection dates, maintenance activities, and any issues identified.

- Training: Train maintenance personnel on proper maintenance procedures and techniques specific to helical couplings.

By following these specialized maintenance routines, you can maximize the longevity and performance of helical couplings in your machinery systems.

editor by CX 2024-04-04

China Standard Ld Diaphragm Speed Reducer Screw Group Helical Drive Flexible Coupling for Encoder Shaft Coupling Dimensions

Product Description

Product Description

DO NOT worry about PRICE, we are manufacturer.

DO NOT worry about QUALITY, we have 16 years experience.

DO NOT worry about AFTER-SALES, we are 24 hours online.

Features :

1. The main body is made of high strength aluminum alloy

2. Zero backlash, suitable for forward and reverse rotation

3.Colloid is made of polyurethane, which has good wear resistance

4.Oil resistance and electrical insulation, the middle elasticbody can absorb vibration

5. Compensate radial, angular and axial deviations

6. Removable design for easy installation

7. Tightening method of positioning screw

Suitable for a wide range of devices

CNC lathes Optical inspection equipment

Module slider Servo motor

Company Profile

Certifications

Packaging & Shipping

All products will be well packed with standard export wooden case or

cartons.

Shafts packed with paper tube or plastic bag;

Linear guideways or lead screwswrapped with film or plastic bag;

Guarantee well protected against dampness,moisture, rust and shock.

Our Advantages

FAQ

Q1: Do you have a catalogue? Can you send me the catalogue to have a check of all your products?

A: Yes , We have product catalogue.Please contact us on line or send an Email to sending the catalogue.

Q2: I can’t find the product on your catalogue, can you make this product for me?

A: Our catalogue shows most of our products,but not all.So just let us know what product do you need.

Q3 : Can you make customized products and customized packing?

A: Yes.We made a lot of customized products for our customer before.And we have many moulds for our customers already.About customized packing,we can put your Logo or other info on the packing.There is no problem.Just have to point out that ,it will cause some additional cost.

Q4: Can you provide samples ? Are the samples free ?

A: Yes,we can provide samples.Normally,we provide 1-2pcs free samples for test or quality checking.But you have to pay for the shipping cos.If you need many items, or need more qty for each item,we will charge for the samples.

Any requirements or question,Welcome to “Send” us an e-mail Now!

It’s our great honor to do services for you! You also can get the FREE SAMPLES soon.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Endurance of Helical Couplings for High Torque and Axial Motion

Helical couplings are designed to withstand a range of mechanical forces, including high levels of torque and axial motion:

- High Torque: Helical couplings are capable of transmitting high levels of torque due to their robust construction and the interlocking helical teeth. The helical design enhances the coupling’s ability to handle torque without compromising flexibility.

- Axial Motion: Helical couplings can accommodate limited axial motion without compromising their performance. This is especially beneficial in applications where shafts might experience slight axial displacement due to thermal expansion or other factors.

Engineers select helical couplings based on the anticipated torque requirements and axial motion characteristics of the application. It’s important to ensure that the selected coupling has the necessary torque rating and axial flexibility to meet the demands of the specific machinery or system.

The Role of Helical Flexibility in Compensating for Shaft Misalignment

Helical couplings are designed with helical cuts or grooves in their construction. This helical design provides flexibility, allowing the coupling to compensate for various types of shaft misalignment:

- Angular Misalignment: The helical cuts enable the coupling to flex in response to angular misalignment between the connected shafts. As the misaligned shafts rotate, the helical flexure allows them to maintain contact and transmit torque effectively.

- Radial Misalignment: Helical couplings can also accommodate radial misalignment by flexing slightly in response to the offset between the shafts. This flexibility prevents binding or excessive forces on the shafts, reducing wear and extending the coupling’s lifespan.

- Axial Misalignment: While not all helical couplings can handle significant axial movement, some designs offer limited axial compensation. The helical flexure allows a small amount of axial displacement without compromising coupling integrity.

Overall, the helical flexibility of these couplings allows them to maintain constant contact and torque transmission even when shafts are not perfectly aligned. This feature enhances the coupling’s reliability, reduces stress on the connected components, and contributes to the longevity of both the coupling and the machinery.

Diagnosing and Addressing Issues with Helical Couplings in Machinery Systems

Diagnosing and addressing issues related to helical couplings in machinery systems require a systematic approach:

- Visual Inspection: Regularly inspect the coupling for signs of wear, misalignment, or damage, such as cracks, corrosion, or deformation.

- Noise and Vibration: Unusual noise or increased vibration can indicate coupling problems. Use vibration analysis tools to identify issues and their severity.

- Power Transmission Issues: If you notice a decrease in power transmission efficiency or sudden changes in torque, it may be due to coupling problems.

- Temperature Changes: Abnormal temperature increases in the coupling area could indicate friction or misalignment issues.

- Lubrication: Check the lubrication of the coupling regularly. Insufficient or contaminated lubricant can lead to increased wear and poor performance.

- Alignment: Ensure that the coupling is properly aligned. Misalignment can cause premature wear and reduce the coupling’s lifespan.

- Fasteners: Examine fasteners like set screws or clamping elements. Loose or damaged fasteners can affect coupling performance.

- Replace Damaged Parts: If you identify worn or damaged parts, replace them promptly with genuine replacement components.

- Balancing: Imbalance can lead to vibration and wear. Balance the coupling if necessary.

- Proper Installation: If the coupling was recently installed, ensure it was installed correctly and according to the manufacturer’s guidelines.

- Consult Experts: If you’re unsure about diagnosing or addressing issues, consult with experts or engineers who specialize in coupling systems.

By conducting regular inspections, monitoring performance, and addressing issues promptly, you can maintain the optimal functioning of helical couplings in your machinery systems.

editor by CX 2024-03-27

China best Ld Diaphragm Speed Reducer Screw Group Helical Drive Flexible Coupling for Encoder Shaft Coupling Dimensions

Product Description

Product Description

DO NOT worry about PRICE, we are manufacturer.

DO NOT worry about QUALITY, we have 16 years experience.

DO NOT worry about AFTER-SALES, we are 24 hours online.

Features :

1. The main body is made of high strength aluminum alloy

2. Zero backlash, suitable for forward and reverse rotation

3.Colloid is made of polyurethane, which has good wear resistance

4.Oil resistance and electrical insulation, the middle elasticbody can absorb vibration

5. Compensate radial, angular and axial deviations

6. Removable design for easy installation

7. Tightening method of positioning screw

Suitable for a wide range of devices

CNC lathes Optical inspection equipment

Module slider Servo motor

Company Profile

Certifications

Packaging & Shipping

All products will be well packed with standard export wooden case or

cartons.

Shafts packed with paper tube or plastic bag;

Linear guideways or lead screwswrapped with film or plastic bag;

Guarantee well protected against dampness,moisture, rust and shock.

Our Advantages

FAQ

Q1: Do you have a catalogue? Can you send me the catalogue to have a check of all your products?

A: Yes , We have product catalogue.Please contact us on line or send an Email to sending the catalogue.

Q2: I can’t find the product on your catalogue, can you make this product for me?

A: Our catalogue shows most of our products,but not all.So just let us know what product do you need.

Q3 : Can you make customized products and customized packing?

A: Yes.We made a lot of customized products for our customer before.And we have many moulds for our customers already.About customized packing,we can put your Logo or other info on the packing.There is no problem.Just have to point out that ,it will cause some additional cost.

Q4: Can you provide samples ? Are the samples free ?

A: Yes,we can provide samples.Normally,we provide 1-2pcs free samples for test or quality checking.But you have to pay for the shipping cos.If you need many items, or need more qty for each item,we will charge for the samples.

Any requirements or question,Welcome to “Send” us an e-mail Now!

It’s our great honor to do services for you! You also can get the FREE SAMPLES soon.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Applications of Helical Couplings in Various Industries

Helical couplings find wide use in numerous industries and applications due to their versatility, reliability, and ability to handle misalignment and transmit torque:

- Manufacturing: Helical couplings are used in CNC machines, mills, lathes, and other manufacturing equipment to ensure precise power transmission and minimize vibration.

- Robotics: Robotic arms and joints often employ helical couplings to connect motors and actuators, allowing for flexibility while maintaining accurate motion control.

- Medical Equipment: Imaging devices, surgical robots, and medical equipment often use helical couplings to ensure precise movement and positioning.

- Aerospace: Helical couplings are used in aerospace applications such as satellite systems, UAVs, and aircraft systems where lightweight yet durable coupling solutions are required.

- Automotive: Helical couplings find use in automotive testing equipment, vehicle assembly lines, and robotics for manufacturing and testing automotive components.

- Packaging and Conveyors: Packaging machinery, material handling systems, and conveyors utilize helical couplings to ensure efficient and accurate movement of products.

- Printing: Printers and labeling machines benefit from helical couplings’ ability to handle misalignment and transmit motion accurately.

The broad range of applications highlights the adaptability and reliability of helical couplings across various industries.

The Role of Helical Flexibility in Compensating for Shaft Misalignment

Helical couplings are designed with helical cuts or grooves in their construction. This helical design provides flexibility, allowing the coupling to compensate for various types of shaft misalignment:

- Angular Misalignment: The helical cuts enable the coupling to flex in response to angular misalignment between the connected shafts. As the misaligned shafts rotate, the helical flexure allows them to maintain contact and transmit torque effectively.

- Radial Misalignment: Helical couplings can also accommodate radial misalignment by flexing slightly in response to the offset between the shafts. This flexibility prevents binding or excessive forces on the shafts, reducing wear and extending the coupling’s lifespan.

- Axial Misalignment: While not all helical couplings can handle significant axial movement, some designs offer limited axial compensation. The helical flexure allows a small amount of axial displacement without compromising coupling integrity.

Overall, the helical flexibility of these couplings allows them to maintain constant contact and torque transmission even when shafts are not perfectly aligned. This feature enhances the coupling’s reliability, reduces stress on the connected components, and contributes to the longevity of both the coupling and the machinery.

Recent Advancements in Helical Coupling Technology

Recent years have seen several advancements and innovations in helical coupling technology, aimed at improving performance, reliability, and ease of use:

- Advanced Materials: Manufacturers are using innovative materials that offer enhanced strength, durability, and resistance to wear, allowing helical couplings to handle higher torque loads and harsh environments.

- Customization: Modern helical couplings can be designed and manufactured with greater customization options to fit specific application requirements, such as unique shaft sizes or complex misalignment conditions.

- Compact Designs: Engineers have developed more compact helical coupling designs that are lightweight and have a smaller footprint, making them ideal for space-constrained applications.

- Improved Torsional Stiffness: Innovations in coupling design have led to improved torsional stiffness, providing better control over torsional vibrations and ensuring precise power transmission.

- Integrated Monitoring: Some advanced helical couplings come with built-in sensors or monitoring systems that can provide real-time data on coupling performance, allowing for predictive maintenance and reducing downtime.

- Enhanced Tolerance for Misalignment: New designs allow helical couplings to handle higher levels of misalignment without sacrificing performance, making them more versatile for various applications.

These advancements continue to make helical couplings a reliable and versatile choice for a wide range of mechanical systems across industries.

editor by CX 2024-02-13

China wholesaler Ld Diaphragm Speed Reducer Screw Group Helical Drive Flexible Coupling for Encoder Shaft Coupling Dimensions

Product Description

Product Description

DO NOT worry about PRICE, we are manufacturer.

DO NOT worry about QUALITY, we have 16 years experience.

DO NOT worry about AFTER-SALES, we are 24 hours online.

Features :

1. The main body is made of high strength aluminum alloy

2. Zero backlash, suitable for forward and reverse rotation

3.Colloid is made of polyurethane, which has good wear resistance

4.Oil resistance and electrical insulation, the middle elasticbody can absorb vibration

5. Compensate radial, angular and axial deviations

6. Removable design for easy installation

7. Tightening method of positioning screw

Suitable for a wide range of devices

CNC lathes Optical inspection equipment

Module slider Servo motor

Company Profile

Certifications

Packaging & Shipping

All products will be well packed with standard export wooden case or

cartons.

Shafts packed with paper tube or plastic bag;

Linear guideways or lead screwswrapped with film or plastic bag;

Guarantee well protected against dampness,moisture, rust and shock.

Our Advantages

FAQ

Q1: Do you have a catalogue? Can you send me the catalogue to have a check of all your products?

A: Yes , We have product catalogue.Please contact us on line or send an Email to sending the catalogue.

Q2: I can’t find the product on your catalogue, can you make this product for me?

A: Our catalogue shows most of our products,but not all.So just let us know what product do you need.

Q3 : Can you make customized products and customized packing?

A: Yes.We made a lot of customized products for our customer before.And we have many moulds for our customers already.About customized packing,we can put your Logo or other info on the packing.There is no problem.Just have to point out that ,it will cause some additional cost.

Q4: Can you provide samples ? Are the samples free ?

A: Yes,we can provide samples.Normally,we provide 1-2pcs free samples for test or quality checking.But you have to pay for the shipping cos.If you need many items, or need more qty for each item,we will charge for the samples.

Any requirements or question,Welcome to “Send” us an e-mail Now!

It’s our great honor to do services for you! You also can get the FREE SAMPLES soon.

Applications of Helical Couplings in Various Industries

Helical couplings find wide use in numerous industries and applications due to their versatility, reliability, and ability to handle misalignment and transmit torque:

- Manufacturing: Helical couplings are used in CNC machines, mills, lathes, and other manufacturing equipment to ensure precise power transmission and minimize vibration.

- Robotics: Robotic arms and joints often employ helical couplings to connect motors and actuators, allowing for flexibility while maintaining accurate motion control.

- Medical Equipment: Imaging devices, surgical robots, and medical equipment often use helical couplings to ensure precise movement and positioning.

- Aerospace: Helical couplings are used in aerospace applications such as satellite systems, UAVs, and aircraft systems where lightweight yet durable coupling solutions are required.

- Automotive: Helical couplings find use in automotive testing equipment, vehicle assembly lines, and robotics for manufacturing and testing automotive components.

- Packaging and Conveyors: Packaging machinery, material handling systems, and conveyors utilize helical couplings to ensure efficient and accurate movement of products.

- Printing: Printers and labeling machines benefit from helical couplings’ ability to handle misalignment and transmit motion accurately.

The broad range of applications highlights the adaptability and reliability of helical couplings across various industries.

Considerations for Choosing a Helical Coupling for Your Application

When selecting a helical coupling for a specific application, several key factors should be considered:

- Torque Capacity: Determine the maximum torque that the coupling will need to transmit in your application. Choose a coupling with a torque capacity that exceeds the application’s requirements.

- Shaft Size: Ensure that the coupling’s bore size matches the diameter of the shafts to be connected. Proper sizing prevents slippage and ensures efficient torque transmission.

- Angular Misalignment: Evaluate the degree of angular misalignment that the coupling needs to accommodate. Different couplings have varying angular misalignment capabilities.

- Radial Misalignment: Consider the amount of radial misalignment that the coupling must handle. Choose a coupling that can accommodate the expected radial displacement.

- Axial Misalignment: If there will be axial movement between the shafts, select a coupling that can handle the required axial displacement without binding.

- Environmental Conditions: Take into account the operating environment, including temperature, humidity, dust, and chemical exposure. Choose a coupling material that is suitable for the conditions.

- Speed: Determine the rotational speed of the shafts. Ensure that the chosen coupling is rated for the application’s speed without causing resonance or vibration issues.

- Backlash: Assess the acceptable level of backlash in your application. Some couplings have minimal backlash, which is critical for precision applications.

- Cost: Consider the budget for your project. While it’s important to choose a reliable coupling, also balance the cost with the performance requirements.

By carefully evaluating these factors and consulting with coupling manufacturers or experts, you can choose the right helical coupling that meets the needs of your specific application.

Best Practices for Lubricating and Preserving the Performance of Helical Couplings

Lubrication is crucial for maintaining the performance and longevity of helical couplings. Here are some best practices to consider:

- Choose the Right Lubricant: Select a lubricant that is compatible with the materials of the coupling and provides adequate protection against wear and corrosion.

- Regular Lubrication: Follow the manufacturer’s guidelines for lubrication intervals. Regularly lubricate the coupling to ensure proper operation and prevent excessive wear.

- Clean Before Lubrication: Clean the coupling and the surrounding area before applying lubricant to prevent contamination.

- Apply the Right Amount: Apply the appropriate amount of lubricant as recommended by the manufacturer. Too much lubricant can lead to excess buildup and attract debris.

- Distribute Evenly: Ensure that the lubricant is evenly distributed across the coupling’s surfaces to provide effective lubrication.

- Monitor Performance: Regularly monitor the coupling’s performance for any signs of increased friction or abnormal operation that may indicate the need for relubrication.

- Inspect for Wear: During maintenance checks, inspect the coupling for signs of wear, corrosion, or damage. Replace the coupling if necessary.

- Protect Against Contaminants: Shield the coupling from dust, dirt, and other contaminants that can degrade the lubricant and cause premature wear.

- Environmental Considerations: If the machinery operates in extreme temperatures, wet or corrosive environments, choose a lubricant that can withstand these conditions.

- Follow Manufacturer’s Recommendations: Always follow the manufacturer’s recommendations for lubrication, maintenance, and storage to ensure optimal coupling performance.

By adhering to these best practices, you can maximize the efficiency, reliability, and lifespan of helical couplings in various mechanical systems.

editor by CX 2023-10-08

China OEM Ld Diaphragm Speed Reducer Screw Group Helical Drive Flexible Coupling for Encoder Shaft Coupling Dimensions

Product Description

Product Description

DO NOT worry about PRICE, we are manufacturer.

DO NOT worry about QUALITY, we have 16 years experience.

DO NOT worry about AFTER-SALES, we are 24 hours online.

Features :

1. The main body is made of high strength aluminum alloy

2. Zero backlash, suitable for forward and reverse rotation

3.Colloid is made of polyurethane, which has good wear resistance

4.Oil resistance and electrical insulation, the middle elasticbody can absorb vibration

5. Compensate radial, angular and axial deviations

6. Removable design for easy installation

7. Tightening method of positioning screw

Suitable for a wide range of devices

CNC lathes Optical inspection equipment

Module slider Servo motor

Company Profile

Certifications

Packaging & Shipping

All products will be well packed with standard export wooden case or

cartons.

Shafts packed with paper tube or plastic bag;

Linear guideways or lead screwswrapped with film or plastic bag;

Guarantee well protected against dampness,moisture, rust and shock.

Our Advantages

FAQ

Q1: Do you have a catalogue? Can you send me the catalogue to have a check of all your products?

A: Yes , We have product catalogue.Please contact us on line or send an Email to sending the catalogue.

Q2: I can’t find the product on your catalogue, can you make this product for me?

A: Our catalogue shows most of our products,but not all.So just let us know what product do you need.

Q3 : Can you make customized products and customized packing?

A: Yes.We made a lot of customized products for our customer before.And we have many moulds for our customers already.About customized packing,we can put your Logo or other info on the packing.There is no problem.Just have to point out that ,it will cause some additional cost.

Q4: Can you provide samples ? Are the samples free ?

A: Yes,we can provide samples.Normally,we provide 1-2pcs free samples for test or quality checking.But you have to pay for the shipping cos.If you need many items, or need more qty for each item,we will charge for the samples.

Any requirements or question,Welcome to “Send” us an e-mail Now!

It’s our great honor to do services for you! You also can get the FREE SAMPLES soon.

Applications of Helical Couplings in Various Industries

Helical couplings find wide use in numerous industries and applications due to their versatility, reliability, and ability to handle misalignment and transmit torque:

- Manufacturing: Helical couplings are used in CNC machines, mills, lathes, and other manufacturing equipment to ensure precise power transmission and minimize vibration.

- Robotics: Robotic arms and joints often employ helical couplings to connect motors and actuators, allowing for flexibility while maintaining accurate motion control.

- Medical Equipment: Imaging devices, surgical robots, and medical equipment often use helical couplings to ensure precise movement and positioning.

- Aerospace: Helical couplings are used in aerospace applications such as satellite systems, UAVs, and aircraft systems where lightweight yet durable coupling solutions are required.

- Automotive: Helical couplings find use in automotive testing equipment, vehicle assembly lines, and robotics for manufacturing and testing automotive components.

- Packaging and Conveyors: Packaging machinery, material handling systems, and conveyors utilize helical couplings to ensure efficient and accurate movement of products.

- Printing: Printers and labeling machines benefit from helical couplings’ ability to handle misalignment and transmit motion accurately.

The broad range of applications highlights the adaptability and reliability of helical couplings across various industries.

Utilization of Helical Couplings in Mechanical Systems

A helical coupling, also known as a beam coupling, is a type of flexible coupling that is used in mechanical systems to transmit torque and motion between shafts while accommodating misalignment. Here’s how it is utilized:

Helical couplings consist of two hubs, each with helical slots that interlock with the other hub’s slots. The interlocking design allows for flexibility in multiple directions while maintaining torsional rigidity.

When utilized in mechanical systems:

- Misalignment Compensation: Helical couplings can handle angular, axial, and parallel misalignments between shafts. The helical slots provide flexibility, allowing for small amounts of misalignment without transmitting excessive stress to connected components.

- Torque Transmission: Helical couplings transmit torque from one shaft to another while minimizing backlash. The helical slot design distributes torque evenly across the coupling’s surface, ensuring efficient power transmission.

- Reduced Vibration: The helical design of the coupling helps absorb shocks and vibrations, contributing to smoother operation and reduced wear on connected components.

- Compact Design: Helical couplings have a compact and lightweight design, making them suitable for applications with limited space.

- Simple Installation: These couplings are relatively easy to install, with minimal maintenance requirements.

- Various Applications: Helical couplings are commonly used in robotics, motion control systems, CNC machines, and other applications where precision and flexibility are essential.

In summary, helical couplings provide an effective solution for transmitting torque and motion between shafts while accommodating misalignment and reducing vibrations in various mechanical systems.

Best Practices for Lubricating and Preserving the Performance of Helical Couplings

Lubrication is crucial for maintaining the performance and longevity of helical couplings. Here are some best practices to consider:

- Choose the Right Lubricant: Select a lubricant that is compatible with the materials of the coupling and provides adequate protection against wear and corrosion.

- Regular Lubrication: Follow the manufacturer’s guidelines for lubrication intervals. Regularly lubricate the coupling to ensure proper operation and prevent excessive wear.

- Clean Before Lubrication: Clean the coupling and the surrounding area before applying lubricant to prevent contamination.

- Apply the Right Amount: Apply the appropriate amount of lubricant as recommended by the manufacturer. Too much lubricant can lead to excess buildup and attract debris.

- Distribute Evenly: Ensure that the lubricant is evenly distributed across the coupling’s surfaces to provide effective lubrication.

- Monitor Performance: Regularly monitor the coupling’s performance for any signs of increased friction or abnormal operation that may indicate the need for relubrication.

- Inspect for Wear: During maintenance checks, inspect the coupling for signs of wear, corrosion, or damage. Replace the coupling if necessary.

- Protect Against Contaminants: Shield the coupling from dust, dirt, and other contaminants that can degrade the lubricant and cause premature wear.

- Environmental Considerations: If the machinery operates in extreme temperatures, wet or corrosive environments, choose a lubricant that can withstand these conditions.

- Follow Manufacturer’s Recommendations: Always follow the manufacturer’s recommendations for lubrication, maintenance, and storage to ensure optimal coupling performance.

By adhering to these best practices, you can maximize the efficiency, reliability, and lifespan of helical couplings in various mechanical systems.

editor by CX 2023-08-09

China wholesaler UL Listed Set Screw Steel Pipe Fitting Coupling From Factory energy coupling

Product Description

EMT Pipe Set Screw Coupling

1. American Standard: UL Standard 514B

2. Material: Zine Die Cast

3. Size: 1/2″ to 4″

4. OEM Service

5. Application: Used to bond electrical metallic tubing

| Type: | Die Cast |

|---|---|

| Technique: | Casting |

| Material: | Zinc |

| Usage: | Construction & Decoration, Electrical |

| Section Shape: | Round |

| Size: | From 1/2" to 4" |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What Is a Coupling?

A coupling is a device used to connect two shafts. It transmits power between them and allows for some misalignment or end movement. There are several types of couplings. The most common ones are gear couplings and planetary couplings. However, there are many others as well.

Transfer of energy

Energy coupling is a process by which two biological reactions are linked by sharing energy. The energy released during one reaction can be used to drive the second. It is a very useful mechanism that synchronizes two biological systems. All cells have two types of reactions, exergonic and endergonic, and they are connected through energy coupling.

This process is important for a number of reasons. The first is that it allows the exchange of electrons and their energy. In a single molecule, this energy transfer involves the exchange of two electrons of different energy and spin. This exchange occurs because of the overlap interaction of two MOs.

Secondly, it is possible to achieve quadratic coupling. This is a phenomenon that occurs in circular membrane resonators when the system is statically deflected. This phenomenon has been gaining a great deal of interest as a mechanism for stronger coupling. If this mechanism is employed in a physical system, energy can be transferred on a nanometer scale.

The magnetic field is another important factor that affects the exchange of energy between semiconductor QWs. A strong magnetic field controls the strength of the coupling and the energy order of the exciton. The magnetic field can also influence the direction of polariton-mediated energy transfer. This mechanism is very promising for controlling the routing of excitation in a semiconductor.

Functions

Couplings play a variety of functions, including transferring power, compensating for misalignment, and absorbing shock. These functions depend on the type of shaft being coupled. There are four basic types: angular, parallel, and symmetrical. In many cases, coupling is necessary to accommodate misalignment.

Couplings are mechanical devices that join two rotating pieces of equipment. They are used to transfer power and allow for a small degree of end-to-end misalignment. This allows them to be used in many different applications, such as the transmission from the gearbox to the differential in an automobile. In addition, couplings can be used to transfer power to spindles.

Types

There are two main types of couplings: rigid and flexible. Rigid couplings are designed to prevent relative motion between the two shafts and are suitable for applications where precise alignment is required. However, high stresses in the case of significant misalignment can cause early failure of the coupling. Flexible couplings, on the other hand, allow for misalignment and allow for torque transmission.

A software application may exhibit different types of coupling. The first type involves the use of data. This means that one module may use data from another module for its operation. A good example of data coupling is the inheritance of an object. In a software application, one module can use another module’s data and parameters.

Another type of coupling is a rigid sleeve coupling. This type of coupling has a pipe with a bore that is finished to a specified tolerance. The pipe contains two threaded holes for transmitting torque. The sleeve is secured by a gib head key. This type of coupling may be used in applications where a couple of shafts are close together.

Other types of coupling include common and external. Common coupling occurs when two modules share global data and communication protocols. This type of coupling can lead to uncontrollable error propagation and unforeseen side effects when changes are made to the system. External coupling, on the other hand, involves two modules sharing an external device interface or communication protocol. Both types of coupling involve a shared code structure and depend on the external modules or hardware.

Mechanical couplings are essential in power transmission. They connect rotating shafts and can either be rigid or flexible, depending on the accuracy required. These couplings are used in pumps, compressors, motors, and generators to transmit power and torque. In addition to transferring power, couplings can also prevent torque overload.

Applications

Different coupling styles are ideal for different applications, and they have different characteristics that influence the coupling’s reliability during operation. These characteristics include stiffness, misalignment capability, ease of installation and maintenance, inherent balance, and speed capability. Selecting the right coupling style for a particular application is essential to minimize performance problems and maximize utility.

It is important to know the requirements for the coupling you choose before you start shopping. A proper selection process takes into account several design criteria, including torque and rpm, acoustic signals, and environmental factors. Once you’ve identified these parameters, you can select the best coupling for the job.

A gear coupling provides a mechanical connection between two rotating shafts. These couplings use gear mesh to transmit torque and power between two shafts. They’re typically used on large industrial machines, but they can also be used in smaller motion control systems. In smaller systems, a zero-backlash coupling design is ideal.

Another type of coupling is the flange coupling. These are easy to manufacture. Their design is similar to a sleeve coupling. But unlike a sleeve coupling, a flange coupling features a keyway on one side and two threaded holes on the other. These couplings are used in medium-duty industrial applications.

Besides being useful for power transmission, couplings can also prevent machine vibration. If vibration occurs in a machine, it can cause it to deviate from its predetermined position, or damage the motor. Couplings, however, help prevent this by absorbing the vibration and shock and preventing damage to expensive parts.

Couplings are heavily used in the industrial machinery and electrical industries. They provide the necessary rotation mechanism required by machinery and other equipment. Coupling suppliers can help customers find the right coupling for a specific application.

Criteria for selecting a coupling

When selecting a coupling for a specific application, there are a number of different factors to consider. These factors vary greatly, as do operating conditions, so selecting the best coupling for your system can be challenging. Some of these factors include horsepower, torque, and speed. You also need to consider the size of the shafts and the geometry of the equipment. Space restrictions and maintenance and installation requirements should also be taken into account. Other considerations can be specific to your system, such as the need for reversing.

First, determine what size coupling you need. The coupling’s size should be able to handle the torque required by the application. In addition, determine the interface connection, such as straight or tapered keyed shafts. Some couplings also feature integral flange connections.

During the specification process, be sure to specify which materials the coupling will be made of. This is important because the material will dictate most of its performance characteristics. Most couplings are made of stainless steel or aluminum, but you can also find ones made of Delrin, titanium, or other engineering-grade materials.

One of the most important factors to consider when selecting a coupling is its torque capability. If the torque rating is not adequate, the coupling can be damaged or break easily. Torque is a major factor in coupling selection, but it is often underestimated. In order to ensure maximum coupling performance, you should also take into consideration the size of the shafts and hubs.

In some cases, a coupling will need lubrication throughout its lifecycle. It may need to be lubricated every six months or even once a year. But there are couplings available that require no lubrication at all. An RBI flexible coupling by CZPT is one such example. Using a coupling of this kind can immediately cut down your total cost of ownership.

editor by CX 2023-07-11

China EMT Fittings Set Screw Coupling UL List coupling distance

Merchandise Description

EMT Established Screw Coupling Zinc

Standard particulars:

| Substance: | Zinc |

| End: | Galvanized |

| Color: |

Silver |

| Variety: | Set Screw / Comperssion |

|

Use: |

For use to bouple 2 finishes of EMT |

| Model Identify: |

TOPELE |

| UL Certificate: | UL No.E506415 |

Specifications:

| Item No: | Measurement: | Dim A(Inch) | Dim B(Inch) |

|

SSCP-fifty |

one/2″ |

one.five hundred | .720 |

|

SSCP-75 |

3/4″ |

1.880 | .945 |

|

SSCP-one hundred |

one” |

two.059 | one.181 |

|

SSCP-a hundred twenty five |

one-1/4″ |

two.504 | one.522 |

|

SSCP-a hundred and fifty |

one-1/2″ |

2.883 | 1.753 |

|

SSCP-200 |

2″ |

3.405 | two.220 |

|

SSCP-250 |

two-1/2″ |

four.000 | 2.913 |

|

SSCP-300 |

three” |

four.488 | 3.563 |

|

SSCP-400 |

4″ |

five.236 | four.488 |

TOPELE EMT Set Screw Coupling Zinc are used in dry area to hook up the ends of 2 unthreaded EMT conduits jointly. CZPT EMT zinc set-screw couplings give concrete limited connections when taped. Furthermore, These set-screw couplings get rid of the need to thread bald conduits to match outdated threaded couplings. EMT conduit couplings are pure zinc material for superb corrosion security in moist place.

FAQ

Q1: Are you manufacture?

A: Indeed,we have manufacturing unit and warehouse in HangZhou HangZhou metropolis.

Q2: How can I request solution samples?

A: The samples are free of charge but courier charge will be collected. Make sure you send out us samples list and courier account quantity.

Q3: How can I ask for a merchandise catalog?

A: The challenging copies of catalogs are free of charge but courier demand will be gathered.

The PDF catalog we can send to you by electronic mail or WeTransfer.

This autumn: What is your payment terms?

A: thirty% T/T deposit,equilibrium against B/L faxed copy

Irrevocable L/C a hundred% at sight and irrevocable.

Q5: How about the shipping and delivery time?

A: Accord to your purchase checklist and amount,mainly supply in 30days.

Why choose us?

one. We are China Leading provide of Electrical Pipe,Strut Channel and Fittings.

two. CZPT is popular model and currently accredited by project engineer in distinct place.

3. Inspected by the Inspection Institution of UL Certification.

4. 100% QC inspection prior to Shipment.

5. Ideal High quality & Ideal Services with Competitive value.

|

US $0.07-2.5 / Piece | |

1,000 Pieces (Min. Order) |

###

| Color: | Silver |

|---|---|

| IP Rating: | IP68 |

| Surface Treatment: | Galvanised |

| Application: | Bouple Two Ends of EMT |

| Material: | Zinc |

| Certification: | UL No.E506415 |

###

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Material: | Zinc |

| Finish: | Galvanized |

| Color: |

Silver |

| Type: | Set Screw / Comperssion |

|

Usage: |

For use to bouple two ends of EMT |

| Brand Name: |

TOPELE |

| UL Certificate: | UL No.E506415 |

###

| Item No: | Size: | Dim A(Inch) | Dim B(Inch) |

|

SSCP-50 |

1/2" |

1.500 | 0.720 |

|

SSCP-75 |

3/4" |

1.880 | 0.945 |

|

SSCP-100 |

1" |

2.059 | 1.181 |

|

SSCP-125 |

1-1/4" |

2.504 | 1.522 |

|

SSCP-150 |

1-1/2" |

2.883 | 1.753 |

|

SSCP-200 |

2" |

3.405 | 2.220 |

|

SSCP-250 |

2-1/2" |

4.000 | 2.913 |

|

SSCP-300 |

3" |

4.488 | 3.563 |

|

SSCP-400 |

4" |

5.236 | 4.488 |

|

US $0.07-2.5 / Piece | |

1,000 Pieces (Min. Order) |

###

| Color: | Silver |

|---|---|

| IP Rating: | IP68 |

| Surface Treatment: | Galvanised |

| Application: | Bouple Two Ends of EMT |

| Material: | Zinc |

| Certification: | UL No.E506415 |

###

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Material: | Zinc |

| Finish: | Galvanized |

| Color: |

Silver |

| Type: | Set Screw / Comperssion |

|

Usage: |

For use to bouple two ends of EMT |

| Brand Name: |

TOPELE |

| UL Certificate: | UL No.E506415 |

###

| Item No: | Size: | Dim A(Inch) | Dim B(Inch) |

|

SSCP-50 |

1/2" |

1.500 | 0.720 |

|

SSCP-75 |

3/4" |

1.880 | 0.945 |

|

SSCP-100 |

1" |

2.059 | 1.181 |

|

SSCP-125 |

1-1/4" |

2.504 | 1.522 |

|

SSCP-150 |

1-1/2" |

2.883 | 1.753 |

|

SSCP-200 |

2" |

3.405 | 2.220 |

|

SSCP-250 |

2-1/2" |

4.000 | 2.913 |

|

SSCP-300 |

3" |

4.488 | 3.563 |

|

SSCP-400 |

4" |

5.236 | 4.488 |

Programming With Couplings

A coupling is a mechanical device that connects two shafts together and transmits power. Its purpose is to join rotating equipment and allows some degree of end-movement or misalignment. There are many different types of couplings. It’s important to choose the right one for your application.

Mechanical connection between two shafts

There are many ways to achieve mechanical connection between two shafts, including the use of a coupling. One common type is the beam coupling, which is also known as a helical coupling. It is used for transmission of torque between two shafts. This type of connection accommodates axial, parallel and angular misalignments.

The hubs and shafts of a worm gear are connected together by a coupling. This mechanical connection allows one shaft to turn another without causing a mechanical failure. This type of coupling is made from sliding or rubbing parts to transfer torque. However, the coupling is not designed to withstand jerks, so it isn’t suitable for high-speed applications.

The use of a coupling is common in machinery and equipment. It helps transmit power from one drive shaft to the other, while adding mechanical flexibility. It is also useful for reducing the impact and vibration caused by misalignment. It also protects the drive shaft components from wear and tear.

A double-hook coupling can be used to provide a uniform angular velocity at the driven shaft. Another example is a double-jointed coupling. A double-jointed coupling can be used to connect shafts that are not directly intersecting. The double-jointed yoke can be used for the same purpose.

A shaft coupling is a device that maintains a strong mechanical connection between two shafts. It transfers motion from one shaft to another, at all loads and misalignments. Unlike a conventional linkage, a shaft coupling isn’t designed to allow relative motion between the two shafts. Couplings often serve several purposes in a machine, but their primary use is torque and power transmission.

Functions that control the flow of another function

One of the simplest programming constructs is a function that controls the flow of another function. A function can take an argument and return a different value, but it must be ready to return before it can pass that value to another function. To do this, you can use the goto statement and the if statement. Another way to control flow is to use a conditional statement.

Criteria for selecting a coupling

There are several important factors to consider when choosing the right coupling. One of the most important factors is coupling stiffness, which depends on the material used and the shape. The stiffness of a coupling determines its ability to resist elastic deformation. A stiff coupling is desirable for certain types of applications, but it’s undesirable for others. Stiffness can reduce the performance of a system if there’s too much inertia. To avoid this, ensure that the coupling you choose is within the recommended limits.

The size of a coupling is also important. Different coupling types can accommodate different shaft sizes and shapes. Some couplings have special features, such as braking and shear pin protection. When choosing a coupling, you should also consider the type of driven equipment. If you need to connect a high-torque motor, for example, you’ll want to choose a gear coupling. Likewise, a high-speed machine may require a disc coupling.

Another factor to consider when selecting a coupling is the torque rating. Despite its importance, it’s often underestimated. The torque rating is defined as the torque of the coupling divided by its OD. In some cases, torque may fluctuate during a cycle, requiring a coupling with a higher torque rating.

Torsionally flexible couplings are also important to consider. Their design should be able to withstand the torque required during operation, as well as the required speed. The coupling should also have a high degree of torsional stiffness, as well as damping. Furthermore, a damping coupling can reduce the energy wasted through vibration.

The sizing of a coupling is also determined by the torque. Many engineers use torque to select the correct coupling size, but they also take into consideration torsional flexibility and torsional stiffness. For example, a shaft may be able to handle large torque without damaging the coupling, while a disk may be unable to handle large amounts of torque.

Besides torque, another important consideration in coupling selection is the cost. While a coupling may be cheaper, it may be less reliable or easier to maintain. Couplings that are difficult to service may not last as long. They may also require frequent maintenance. If that’s the case, consider purchasing a coupling with a low service factor.

There are many different types of couplings. Some require additional lubrication throughout their lifetime, while others are 100% lubrication-free. An example of a 100% lubrication-free coupling is the RBI flexible coupling from CZPT. This type of coupling can significantly reduce your total cost of ownership.

In addition to the above-mentioned benefits, elastomeric couplings are low-cost and need little maintenance. While they are often cheaper than metallic couplings, they also have excellent shock absorption and vibration dampening properties. However, they are susceptible to high temperatures. Also, they are difficult to balance as an assembly, and have limited overload torque capacity.

editor by czh 2022-12-29

China Chain and sprocket factory : Accept industrial roller chain tensioner in Havana Cuba Custom Powder Screw Filling Machine with Hopper with ce certificate top quality low price

We – EPG Team the biggest Chain and agricultural gearbox manufacturing unit in China with 5 distinct branches. For a lot more information: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

We are seeking forward to developing successful organization relationships with new consumers around the world in the long term.engineering EPG is a specialist producer and exporter that is worried with the layout, advancement and production.course chains & precision roller chains. Single strand chain, multi-strand chains, double pitch chains, corrosion resistant chains, self-lubricating chains, attachment chains, leaf chains, and specialty chains. EPG is a leading provider of high top quality, price-successful power transmission components. As our merchandise strains proceed to increase to fulfill our customer’s wants, our commitment to customized buyer support and on-time delivery continues to be next to none. Application:

It is applied in different market: In food processing market, it is for conveying flour, powder additives, seasoning powder ect. In chemical coatings sector, it is go well with for cement, putty powder, raw substance and so forth.

Introductions:

This is inclined screw elevator used to transport powder solution from a single station to the other! The auger conveyor machine’s primary component is the screw auger, conveyor tube and the motorgear. The screw auger flight is configurated inside the conveyor tube, it is driven by the motor. When the auger shaft rotates the auger will revolute and driven the powder moves. Auger conveyor is edge is match for powder merchandise that is bad fluidity. Also it is go well with for fantastic granule merchandise, these kinds of as sand.

StHangZhourd Characteristics:

1: Electrical power Supply: 3 Period 208-415V 50-60Hz

2: Charging angle: StHangZhourd forty five diploma, 30~60 diploma are also offered.

3: Lifting Peak: StHangZhourd 1.eighty five meters,1 – 5 M could be developed and created

4:Foods quality Conveying screw, Mixer and power box are optional.

5: StHangZhourd hopper quantity 200L, 50-500L are optional

six.The workbench is made of PVC material which can protect the external appearance of products.

seven. Conveyor speed can be adjusted freely from 0~6m/min, operate easily and use conveniently.

eight. It adapts universal castors with brake which can fix and move easily.

nine. It is not only can realize automation to work with robot by connecting peripheral signal but also can work independently.

ten.The THCM Series conveyor belt adjusted aluminum alloy frame which the height can be adjusted according to requirements.

eleven.Customized spec is available according to customers’ special requirement.

Complex information:

| Title | Design | Size (mm) | Weight (kg) | Powervoltage (kw/v) | Capability |

| Horizontal ribbon mixer (spherical) | RHDF-440 | 2250*720*1700 | 260 | 2.2/380 | 350L/time |

| Horizontal ribbon mixer (U type) | RHDF-550 | 2250*800*1700 | 380 | three/380 | 450L/time |

| Horizontal ribbon mixer (round) | RHDF-870 | 2600*920*1980 | 560 | five.5/380 | 750L/time |

| Horizontal ribbon mixer (U sort) | RHDF-1160 | 2600*1571*2050 | seven-hundred | seven.5/380 | 1000L/time |

| Horizontal ribbon mixer (round) | RHDF-1650 | 2800*1160*2200 | 800 | eleven/380 | 1500Ltime |

| Horizontal ribbon mixer (U variety) | RHDF-2100 | 2800*1280*2300 | 850 | fifteen/380 | 2000Ltime |

EPT manner EPT can be personalized:

|

|

Welcome to speak to us for far more specifics!

The use of original products manufacturer’s (OEM) part numbers or emblems , e.g. CASE® and John Deere® are for reference needs only and for indicating item use and compatibility. Our organization and the shown substitution elements contained herein are not sponsored, approved, or made by the OEM.

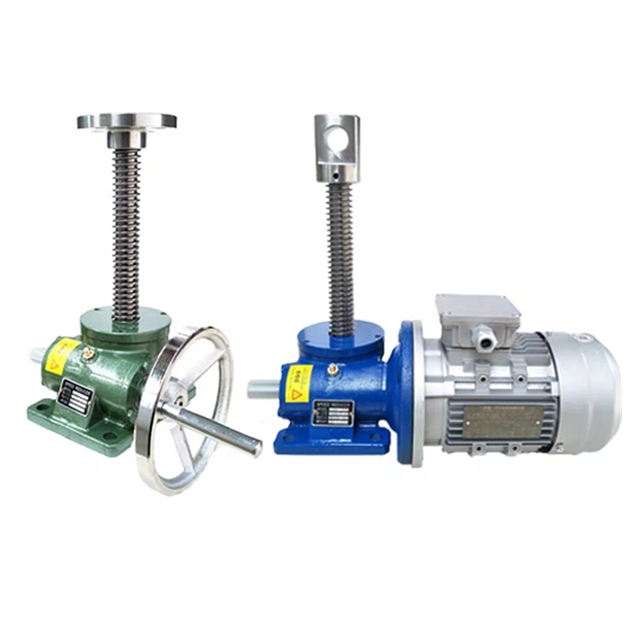

SWL manufacturer exporter type lifting worm gear screw jack SWL 2.5 screw elevator for 0.37kw motor

We have exported our goods to Korea, Turkey, Bulgaria, Romania, Russia, Italy, Norway, the Usa, Canada, and so on.

Overview

Fast Information

- Relevant Industries:

-

Manufacturing Plant

- Manufacturer Title:

-

OEM

- Item NO:

-

SYF

- Design:

-

SWL2.5-SWL35

- Software:

-

Lifting

- Content:

-

Forged Iron

- Guarantee:

-

1-2 Several years

- Shade:

-

Buyer Ask for

- Certification:

-

ISO9001

Packaging & Delivery

-

Lead Time

: -

Amount(Pieces) one – two three – 5 >5 Est. Time(days) 4 12 To be negotiated

On the web Customization

Merchandise Description

SWL Worm Gear Screw Jack

SWL series worm wheel screw elevator is extensively utilized in idustries this kind of as equipment. meallurgy, design, and hydraulie gear, and has a lot of functions this sort of as lfting and pushing and turming with the assist of acessories or modifying peak and placement.

This collection worm screw elevator is one model of standard hoisting components and has numerous features of compact framework, small volume, light weight, wide generate sources, low sound, high reliabilit, and lengthy lifespan. In addition, they are straightforward to be mounted,versatile in use and enjoy multiple functions.

This series, driven by motor or other energy or manually, can be used both solitary and mixed with other folks to correctly control the adjustment of top of lfting or pushing by specific applications. For there are several buildings and mounting situation, the lfting height can be modified to the clients rquirements.

|

SWL two.5 M-one A-Ⅱ-500 FZ |

||||||||||||||

|

SWL |

2.5 |

M |

one |

A |

Ⅱ |

500 |

FZ |

|||||||

|

worm equipment screw jack |

bearing capacity(25kN) |

Ratio Code |

structural kind code |

structure |

assembly form |

Screw stroke(mm) |

Protection sort code |

|||||||

SWL Worm Gear Screw Jack Mounting Dimensions

Observe:

1. The allowable energy is a parameter under the problem that the ambient temperature is 20℃ and the doing work length charge is 20% for every hour.The whole effectiveness is the parameter beneath the problem of grease lubrication.3. The allowable torque, energy and velocity are different when lifting different loads, and the energy of distinct commencing length is different4. For the carry with double information sleeve, the screw can bear lateral power as nicely as axial force.The radial force that the worm shaft extension is authorized to bear is permitted to put in equipment, sprocket or pulley.six. Seek advice from the maker for the over information.seven. It can be self-locked at relaxation.

SWL Worm Gear Screw Jack Features:

one. Compact composition, tiny volume and practical set up

2. High dependability and prolonged life.

3. It has numerous capabilities, this kind of as lifting, descending, pushing and flipping with auxiliary components.

four. It can be used by yourself or in mixture.

five.The energy supply is extensive. It can be pushed immediately by motor or other energy or manually.

ninety four Copper Worm Wheel

94 Copper Worm Wheel with Substantial Dress in Resistance.

Substantial High quality SHELL Substance

The box body which is cleaned by skilled screening and washing gear to ensure that the internal cavity of the box body is cleaner with out iron filings.

Our Organization

HANGZHOU Ever-Energy Team, 1 OF THE Most significant GEARBOX Factory IN CHINA, ELECTROMECHANICAL Tools Supply STATION

Our business is located in the city of HangZhou, ZheJiang Province of China.

We take care of the items of electrical power transmission, our strains primarily go over sequence merchandise in velocity reducers, gearboxes , linked electricial motors and other electrical power transmission equipment. Primarily based on the functional functions, our products can be utilized in several fields: equipment of squander h2o therapy, dredgers, chemical market, cranes, metallic functioning mills, conveyors, paper sector, cement sector, cableways and so on.With the superb good quality and affordable price , our items get pleasure from a very good popularity from customers and the peers all more than the globe.

Additionally, the R&D expenditure are yearly rising for the purpose of much better assembly the new demands of our clients and adapting the new inclination of the market.

Relying on the concepts of honestly operating and mutual reward, We sincerely seem ahead to cooperating with you.

Application region

SWL series worm and screw elevators are broadly employed in machinery, metallurgy, construction, drinking water conservancy gear and other industries. They have the functions of lifting, descending, advancing by auxiliary areas, turning above and other peak adjustment features.

Packing&Transportion

PACKING AND TRANSPORTION

●Packaging: In get to ensure the integrity of merchandise look, we will select cartons, wooden pallets and picket pallets in accordance to customer demands.

●Delivery time: Each reducer is made and examined in accordance with stringent and fixed techniques to make sure that the high quality is appropriate prior to leaving the manufacturing facility and delivery on time.

●Transportation method: We will pick the most appropriate manner of transportation for our customers according to the weight and measurement of the items. We can also pick the method of transportation in accordance to the demands of our clients.

●Receiving and following-sales provider: Soon after getting the merchandise, make sure you verify whether or not they are in excellent problem. We will supply buyers with ideal following-revenue services.

FAQ

Q1: Are you a investing company or a company ?

A: We are a manufacturer in ZheJiang Province, China. Our organization owns the capability of producing, processing,creating and R&D. We welcome your go to.

Q2: How we decide on versions and specifications?

A: According to the distinct particulars of the needs from the portion of enquiry, we will suggest the products’ types upon synthesizing the factors of subject of goods utilization, electricity, torque arm and ratio…

Q3: How is your cost? Can you provide any low cost?

A: Our prices are always competitive. If the buyer can area a huge buy, we definitely will enable price cut.

Q4: How extended need to I hold out for the feedback right after I send out the enquiry?

A4: We will reply the enquiries without having any delay, twelve hours at most.

Q5: What is your solution guarantee period of time?

A: We have the certifications of ISO99001,CE, SGS.

Q6: What industries are your gearboxes becoming utilized?

A: Our gearboxes are widely used to metallurgical tools, mining products, automation equipment, foods machinery, packaging gear, tobacco tools and so on.

Ratio China 6 SWL screw lift jack worm screw elevator SWL5 screw jack electric motor 1.1kw – Supplier Manufacturer wholesaler Factory

For a lot more details.: Cell/Whatpp: +8613083988828

One direction Free WHEEL (RA) One direction PAWL torque limiter (SW) Disc torque limiter clutch with spring (FFT)SPECIFICATION eleven HELICAL Gear BOX 90 Diploma SHAFTS Suited FOR AGRICULTURAL IMPLEMENTS Item Description We are a exclusive entity in the industry, actively committed in direction of producing a qualitative range of Agriculture Gearbox.Because of to our extensive item assortment and rich experiences in this market, we are self-assured to provide our clients adaptable and diversified solutions.We warmly welcome the pals from all the entire world!

Overview

Fast Information

- Applicable Industries:

-

Producing Plant

- Brand name Title:

-

OEM

- Product NO:

-

SYF

- Application:

-

Lifting Transpor

- Certificate:

-

ISO 9001

- Housing Materials:

-

Solid Iron HT200

- Output Form:

-

Shaft/Flange Output

- Lifting velocity:

-

.044-two.592m/min

- Worm speed:

-

50-1800rpm

- Mounting Position:

-

Foot Mounted. Flange Mounted

- Substance:

-

Cooper Wheel

Packaging & Shipping and delivery

-

Lead Time

: -

Amount(Sets) 1 – 3 4 – 5 >5 Est. Time(days) five ten To be negotiated

On the web Customization

Item Description

SWL Worm Gear Screw Jack

SWL series worm wheel screw elevator is commonly used in idustries such as machinery. meallurgy, building, and hydraulie tools, and has many functions this kind of as lfting and pushing and turming with the help of acessories or altering height and place.

This collection worm screw elevator is 1 design of standard hoisting components and has numerous characteristics of compact composition, tiny volume, light-weight bodyweight, extensive generate resources, lower sounds, substantial reliabilit, and prolonged lifespan. In addition, they are easy to be mounted,flexible in use and get pleasure from a number of capabilities.

This collection, driven by motor or other electrical power or manually, can be used equally one and combined with other people to properly handle the adjustment of height of lfting or pushing by certain plans. For there are several buildings and mounting situation, the lfting top can be adjusted to the clients rquirements.

|

SWL 2.5 M-1 A-Ⅱ-500 FZ |

||||||||||||||

|

SWL |

2.five |

M |

1 |

A |

Ⅱ |

500 |

FZ |

|||||||

|

worm gear screw jack |

bearing ability(25kN) |

Ratio Code |

structural type code |

framework |

assembly kind |

Screw stroke(mm) |

Security sort code |

|||||||

SWL Worm Gear Screw Jack Mounting Proportions

Note:

1. The allowable electricity is a parameter below the situation that the ambient temperature is 20℃ and the operating length rate is twenty% per hour.The whole efficiency is the parameter underneath the situation of grease lubrication.three. The allowable torque, energy and velocity are different when lifting different masses, and the electrical power of various starting up period is different4. For the lift with double guide sleeve, the screw can bear lateral power as nicely as axial power.The radial power that the worm shaft extension is authorized to bear is permitted to set up gear, sprocket or pulley.6. Check with the producer for the earlier mentioned knowledge.seven. It can be self-locked at relaxation.

SWL Worm Equipment Screw Jack Features:

one. Compact composition, modest volume and handy set up

two. High trustworthiness and prolonged lifestyle.

three. It has several functions, this sort of as lifting, descending, pushing and flipping with auxiliary elements.

four. It can be utilized on your own or in blend.

five.The electrical power supply is in depth. It can be pushed directly by motor or other power or manually.

94 Copper Worm Wheel

ninety four Copper Worm Wheel with Higher Wear Resistance.

High Quality SHELL Materials

The box body which is cleaned by professional screening and washing products to make certain that the interior cavity of the box entire body is cleaner without iron filings.

Our Company

HANGZHOU Ever-Power Group, One particular OF THE Largest GEARBOX Manufacturing unit IN CHINA, ELECTROMECHANICAL Equipment Supply STATION

Our firm is located in the metropolis of HangZhou, ZheJiang Province of China.

We take care of the goods of electrical power transmission, our strains largely include series merchandise in pace gearboxes, gearboxes , related electricial motors and other energy transmission accessories. Primarily based on the functional features, our goods can be used in several fields: devices of squander water treatment method, dredgers, chemical business, cranes, metal doing work mills, conveyors, paper industry, cement business, cableways and so on.With the superb quality and sensible cost , our merchandise get pleasure from a good track record from customers and the peers all above the globe.

Moreover, the R&D expense are every year rising for the function of much better conference the new requires of our consumers and adapting the new inclination of the sector.

Based on the concepts of actually operating and mutual reward, We sincerely appear forward to cooperating with you.

Software location

SWL collection worm and screw elevators are broadly used in equipment, metallurgy, design, water conservancy equipment and other industries. They have the capabilities of lifting, descending, advancing by auxiliary areas, turning over and other top adjustment functions.

Packing&Transportion

PACKING AND TRANSPORTION

●Packaging: In get to ensure the integrity of solution visual appeal, we will decide on cartons, picket pallets and picket pallets according to buyer requirements.

●Delivery time: Each gearbox is produced and tested in accordance with rigorous and set techniques to make sure that the quality is correct ahead of leaving the manufacturing unit and shipping and delivery on time.

●Transportation manner: We will pick the most appropriate manner of transportation for our buyers according to the weight and dimensions of the products. We can also decide on the mode of transportation according to the needs of our customers.

●Receiving and following-revenue services: Following acquiring the goods, please examine whether they are in very good situation. We will supply customers with perfect soon after-product sales support.

FAQ

Q1: Are you a investing business or a maker ?

A: We are a producer in ZheJiang Province, China. Our company owns the capability of producing, processing,creating and R&D. We welcome your visit.

Q2: How we select types and specifications?

A: In accordance to the certain details of the calls for from the element of enquiry, we will recommend the products’ versions upon synthesizing the factors of discipline of products utilization, energy, torque arm and ratio…

Q3: How is your cost? Can you offer you any price cut?

A: Our rates are always competitive. If the client can location a big purchase, we surely will enable price reduction.

This autumn: How long must I hold out for the opinions after I send the enquiry?

A4: We will reply the enquiries with no any delay, twelve hours at most.

Q5: What is your solution guarantee interval?

A: We have the certifications of ISO99001,CE, SGS.

Q6: What industries are your gearboxes becoming employed?

A: Our gearboxes are widely utilized to metallurgical products, mining gear, automation tools, foodstuff equipment, packaging tools, tobacco gear and so on.

EPG – a single of the greatest transmission factory in China, main goods: worm geared motors, agricultrual gearbox, planetary gear push, helical,screw, beve gears and spare components and agricultural parts manunfacuter in China /For far more details.: Cellular/Whatpp: +8613083988828