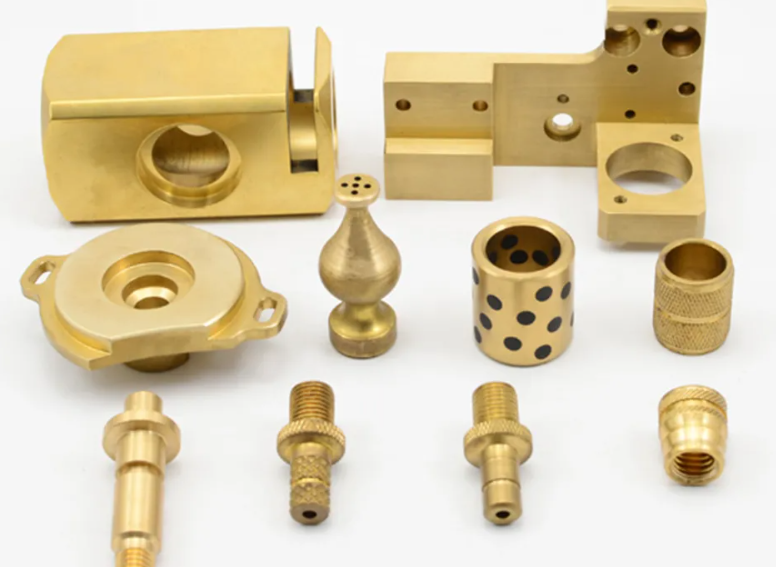

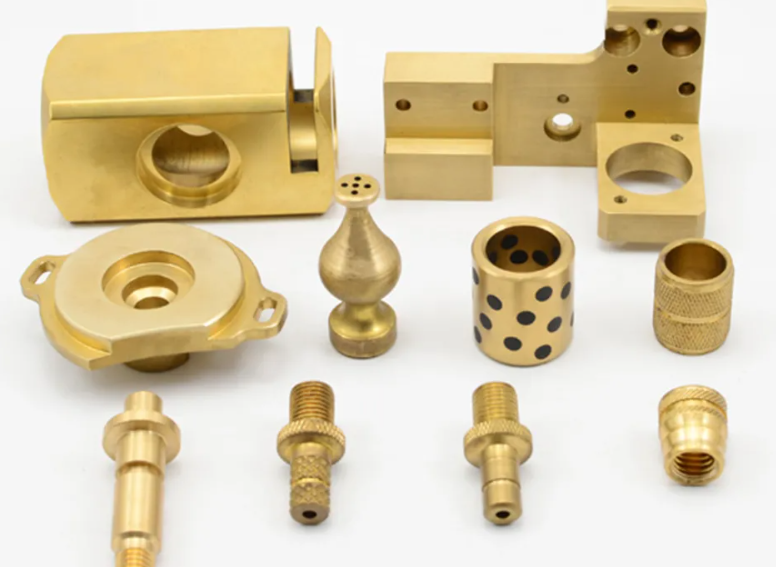

Product Description

Our Services

Product Design Material Selection

Mold Design Mold Making

Bulk Production Logo Printing

Surface Treatment Assembling

Packaging Door to Door Delivery

Product Details

| Material | Nylon ,mc nylon, POM,ABS,PU,PP,PE,PTFE,UHMWPE,HDPE,LDPE, PVC,etc. |

| Color | Black, white, red, green, transparent or any color according to Pantone code |

| Size | As per customer’s requirements |

| Technology | Injection molding, CNC machining, Extrusion |

| Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

| Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

| Shippment | We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured |

Detail Image

Our Factory

Our Certification

Zhongde is an SGS-verified manufacturer. We have passed ISO9001:2005 quality control certification as well as environment management certification.

Our Factory

CHINAMFG is a leading manufacture of OEM parts in rubber & plastic & metal parts. We are always pursuing providing better quality products in shorter period. With a knowledgeable team which has experience in molding and production, we are confident to help you develop and manufacture your product.

Our Machine

We have different types of machines to meet different requriements. Most our machines were imported from overseal. The highest rotate speed of CNC machining center can reach to 20,000RPM. The largest vulcanize rubber machine can produce rubber parts within 3000mm.

Customization Capabilities

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Comparison of Helical Couplings with Beam Couplings and Oldham Couplings

Helical couplings, beam couplings, and Oldham couplings are all flexible coupling types used in mechanical systems, but they differ in design and characteristics:

- Helical Couplings: Helical couplings offer high torque transmission, axial flexibility, and some angular misalignment compensation. They are known for their helical-cut grooves that provide flexibility and compensate for misalignment, making them suitable for applications with moderate misalignment.

- Beam Couplings: Beam couplings consist of one or more flexible beams that provide radial flexibility and angular misalignment compensation. They excel in applications requiring high precision and low torque. However, they have limitations in transmitting high torque and axial misalignment.

- Oldham Couplings: Oldham couplings use two hubs and a center disc to transmit torque while accommodating angular misalignment. They offer higher torsional stiffness compared to helical and beam couplings. Oldham couplings are suitable for applications with moderate torque transmission and angular misalignment.

When comparing these coupling types:

- Helical couplings are preferred for applications with moderate torque, axial flexibility, and moderate angular misalignment.

- Beam couplings are chosen for applications requiring precision motion, low torque, and minimal angular misalignment.

- Oldham couplings are used when higher torsional stiffness and moderate angular misalignment compensation are needed.

The choice depends on factors such as torque requirements, misalignment, precision, and the specific needs of the application. Each coupling type offers unique benefits and limitations, allowing engineers to select the most suitable coupling for their machinery systems.

Utilization of Helical Couplings in Mechanical Systems

A helical coupling, also known as a beam coupling, is a type of flexible coupling that is used in mechanical systems to transmit torque and motion between shafts while accommodating misalignment. Here’s how it is utilized:

Helical couplings consist of two hubs, each with helical slots that interlock with the other hub’s slots. The interlocking design allows for flexibility in multiple directions while maintaining torsional rigidity.

When utilized in mechanical systems:

- Misalignment Compensation: Helical couplings can handle angular, axial, and parallel misalignments between shafts. The helical slots provide flexibility, allowing for small amounts of misalignment without transmitting excessive stress to connected components.

- Torque Transmission: Helical couplings transmit torque from one shaft to another while minimizing backlash. The helical slot design distributes torque evenly across the coupling’s surface, ensuring efficient power transmission.

- Reduced Vibration: The helical design of the coupling helps absorb shocks and vibrations, contributing to smoother operation and reduced wear on connected components.

- Compact Design: Helical couplings have a compact and lightweight design, making them suitable for applications with limited space.

- Simple Installation: These couplings are relatively easy to install, with minimal maintenance requirements.

- Various Applications: Helical couplings are commonly used in robotics, motion control systems, CNC machines, and other applications where precision and flexibility are essential.

In summary, helical couplings provide an effective solution for transmitting torque and motion between shafts while accommodating misalignment and reducing vibrations in various mechanical systems.

Elaboration on Torsional Stiffness in Relation to Helical Couplings and Its Significance

Torsional stiffness refers to the resistance of a helical coupling to twisting or rotational deformation under a certain amount of torque. It is a crucial mechanical property that impacts the performance of helical couplings:

- Response to Torque: A coupling with higher torsional stiffness can transmit torque more efficiently and accurately, resulting in better power transmission.

- Reduced Torsional Deflection: High torsional stiffness minimizes torsional deflection, which is the angular twist experienced by the coupling under torque. This is especially important in precision applications where accurate angular positioning is required.

- Minimized Backlash: Torsional stiffness helps reduce backlash, which is the angular play or movement between connected shafts when the direction of torque changes.

- Dynamic Performance: Torsional stiffness contributes to the coupling’s ability to respond quickly to changes in torque, making it suitable for applications with rapidly changing loads.

- Vibration Damping: While helical couplings provide some level of flexibility to accommodate misalignment, their torsional stiffness helps dampen vibrations and resonances.

- Torsional Resonances: In applications where torsional resonances can occur, a well-matched torsional stiffness can help avoid critical speeds and potential mechanical failures.

When selecting a helical coupling, considering its torsional stiffness in relation to the application’s torque requirements and performance demands is essential to ensure optimal functionality and durability.

editor by CX 2024-02-10

OEM made in China – replacement parts – in Bhiwandi India Machining Worm Spur Bevel Gear with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 distinct branches. For much more information: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Q:What`s the MOQ of your goods?

A:1 set,we can also offer with the sample get. and the huge-quantity.

Q:How could i know if the item suitable for my machine?

A:Our revenue will speak to with you to make positive the certain dimensions,information and EPT critical detai EPT of your aimed items.We make sure all the items fit for your equipment.

Q:I want to uncover a new supplier for goods,can you?

A:Certain,we can give the whole working day service for your consulting,we goal at becoming your mo EPT important supplier.

Q:What`s the payment phrases of the get?

A:As your necessity,we can acknowledge numerous kinds of payment phrases.

The use of original products manufacturer’s (OEM) element quantities or trademarks , e.g. CASE® and John Deere® are for reference needs only and for indicating product use and compatibility. Our business and the shown alternative areas contained herein are not sponsored, approved, or created by the OEM.

OEM made in China – replacement parts – in Chon Buri Thailand Conveyor Sprocket with Carbon Structural Steel Advanced Gear Milling with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Specification

1.Solution name: EPT Sprocket with Carbon Structural Steel Advanced Equipment Milling

Simplex, Duplex, Triplex sprocket

2.Content:Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

Steel:C45(K1045), C46(K1046),C20.

Brass:C36000 ( C26800), C37700 ( HPb59),

Iron: 1213, 12L14,1215

Aluminum: Al6061, Al6063

3.Normal:ISO606ANSI B29.1DIN8187And GB124-97We have proven Good quality system Management in accordance with ISO9001-2000.

4.Origin:HangZhou, Jiansu, China.

5.Surface area Remedy:Teeth Harden, carburizing, chemical black end, paint spraying.

6.Customer’s drawings of sprockets are welcome.

seven.We can provide products according to customer’s drawing, which includes gears, sprockets, shafts, taper bush, castings, forgings, and EPT transmission components manufacturing.

Software

These industrial Equipment & Parts are used in large scale machinery and equipment, such as electricity driving, conveyor, lifting, mine, agricultural, foodstuff industry and so forth.

The use of first products manufacturer’s (OEM) element numbers or trademarks , e.g. CASE® and John Deere® are for reference needs only and for indicating product use and compatibility. Our firm and the detailed substitute elements contained herein are not sponsored, accredited, or created by the OEM.

Best China manufacturer & factory Supply customized OEM precision precision cnc machining service gear wheel material With high quality best price

EPG is one of the biggest manufacturers in China. We have advanced machines for production and new technology testing ability . Through adopting new technology from British, German, U.S.A, our products are best sellers all over European, America, and Southeast Asia.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

- Local Service Location:

-

None

- OEM Service:

-

Support

- Tolerance:

-

PTO Shaft A PTO Adapter will be useful when operating Victory’s EMSD and EMHD Embankment Flail mowers. The absence of a PTO Adapter could cause the PTO shaft to conflict with the arm weldment, which connects to the CAT I/II 3 point hitch.

0.01-0.05mm or Customized

- Certification:

-

ISO9001, SGS

- Surface Treatment:

-

Sandblasting,Polishing,Anodize, Zinc,Nickel,Chrome,Plating, etc.

- Application:

-

Automobile,Medical Equipments,Electric Appliance,Hardware,etc.

-

Dimension:

Our company has solid economic strength, builds up a technician team contingent with high quality, possesses the production assembly line of technicalization in China and perfect system checking on product quality and runs marketing networks throughout the country. -

As Customers’ Request

- Equipment:

-

Milling/Lathe/Drilling/Four/Three Axis CNC Machining Center

-

The range covers: torque ratings up to 4700Nm continuous torque ratings up to 7800Nm peak (12,800Nm maximum emergency stop torque) input speed 6000 maximum backlash down to 0.5 arc-min solid, hollow and robot flange output shaft options

- Drawing Format:

-

PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

Supply Ability

- Supply Ability:

- 10000 Piece/Pieces per Month

Packaging & Delivery

- Port

- nb

-

Lead Time

: -

Quantity(Pieces) 1 – 500 >500 Est. Time(days) 30 To be negotiated

Online Customization

|

Product Name |

Supply customized OEM precision precision cnc machining service gear wheel material |

|

Product Type |

CNC turning, milling, drilling, grinding, wire EDM cutting etc. |

|

Our Services |

CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Making,etc |

|

Material |

Aluminum,Brass,Stainless Steel,Copper,Plastic,Wood,Silicone,Rubber,Or as per the customers’ requirements |

|

Surface Treatment |

Anodizing,Sandblasting,Painting,Powder coating,Plating,Silk Printing,Brushing,Polishing,Laser Engraving |

|

Dimension |

As customers’ request |

|

Service Project |

To provide production design, production and technical service, mould development and processing, etc |

|

Drawing Format |

PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE |

|

Testing Machine |

Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

|

Industry used |

Machinery; heavy duty equipment; electronic device; Auto spare parts; optical telecommunication |

|

Packing |

Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes |

|

Trial sample time |

7-10 days after confirmation |

|

Delivery time |

7-30 days after receive the pre-payments |

|

Payment Terms |

T/T,Western Union,Paypal |