Product Description

| Product Name | Coupling | Place of origin | China |

| Brand | Mighty | Material | Aluminium |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Industry Standards and Guidelines for Helical Couplings

While there are no specific industry standards dedicated solely to helical couplings, their design and application are influenced by general coupling standards and guidelines:

- AGMA Standard: The American Gear Manufacturers Association (AGMA) provides guidelines and standards related to couplings, including helical couplings. Their standards cover aspects like design, selection, and application considerations for flexible couplings.

- ISO Standards: The International Organization for Standardization (ISO) also offers standards related to flexible couplings. ISO standards provide recommendations for design principles, performance characteristics, and testing procedures.

- Manufacturer Recommendations: Coupling manufacturers often provide specific guidelines for the design, installation, and maintenance of their products. These recommendations are based on engineering principles and practical experience.

When designing and using helical couplings, engineers should consider these industry standards and guidelines to ensure proper performance, reliability, and safety. Adhering to recognized standards helps ensure that helical couplings are selected, installed, and operated correctly in various mechanical systems.

Advantages of Using Helical Couplings in Industrial Applications

Helical couplings offer several key advantages when used in industrial applications:

- Misalignment Compensation: Helical couplings can accommodate angular, axial, and parallel misalignments between shafts, helping to extend the lifespan of connected components and reducing the risk of premature failure.

- High Torque Transmission: These couplings are designed to transmit high levels of torque between shafts, making them suitable for applications that require efficient power transmission.

- Backlash Reduction: The helical design minimizes backlash, ensuring accurate positioning and motion control in precision applications.

- Shock and Vibration Absorption: Helical couplings absorb shocks and vibrations, protecting connected equipment from excessive wear and minimizing noise in the system.

- Compact and Lightweight: The compact and lightweight design of helical couplings makes them ideal for applications with limited space and weight constraints.

- Easy Installation: Helical couplings are relatively simple to install, requiring minimal tools and expertise.

- Corrosion Resistance: Many helical couplings are made from materials that offer corrosion resistance, making them suitable for various environmental conditions.

- Cost-Effective: Helical couplings provide a cost-effective solution for flexible shaft connections, reducing the need for complex and expensive alignment procedures.

- Long Service Life: Properly installed and maintained helical couplings can have a long service life, contributing to the reliability of the overall system.

Overall, helical couplings are a versatile and reliable choice for industrial applications that require torque transmission, misalignment compensation, and vibration reduction.

Best Practices for Lubricating and Preserving the Performance of Helical Couplings

Lubrication is crucial for maintaining the performance and longevity of helical couplings. Here are some best practices to consider:

- Choose the Right Lubricant: Select a lubricant that is compatible with the materials of the coupling and provides adequate protection against wear and corrosion.

- Regular Lubrication: Follow the manufacturer’s guidelines for lubrication intervals. Regularly lubricate the coupling to ensure proper operation and prevent excessive wear.

- Clean Before Lubrication: Clean the coupling and the surrounding area before applying lubricant to prevent contamination.

- Apply the Right Amount: Apply the appropriate amount of lubricant as recommended by the manufacturer. Too much lubricant can lead to excess buildup and attract debris.

- Distribute Evenly: Ensure that the lubricant is evenly distributed across the coupling’s surfaces to provide effective lubrication.

- Monitor Performance: Regularly monitor the coupling’s performance for any signs of increased friction or abnormal operation that may indicate the need for relubrication.

- Inspect for Wear: During maintenance checks, inspect the coupling for signs of wear, corrosion, or damage. Replace the coupling if necessary.

- Protect Against Contaminants: Shield the coupling from dust, dirt, and other contaminants that can degrade the lubricant and cause premature wear.

- Environmental Considerations: If the machinery operates in extreme temperatures, wet or corrosive environments, choose a lubricant that can withstand these conditions.

- Follow Manufacturer’s Recommendations: Always follow the manufacturer’s recommendations for lubrication, maintenance, and storage to ensure optimal coupling performance.

By adhering to these best practices, you can maximize the efficiency, reliability, and lifespan of helical couplings in various mechanical systems.

editor by CX 2024-05-15

China supplier Setscrew Couplings High Torque Helical Flexible Shaft Couplings OEM Aluminum

Product Description

Coupling,

1. The couplings offer a range of hub and element selection to meet different demands.

2. They can absorb shock and cater for incidental misalignment and damp out small amplitude vibrations.

3. NBR, Urethane, Hytrel elements.

4. Customized requirement is available.

Main Products:

1. Timing Belt Pulley (Synchronous Pulley), Timing Bar, Clamping Plate;

2. Forging, Casting, Stampling Part;

3. V Belt Pulley and Taper Lock Bush; Sprocket, Idler and Plate Wheel;Spur Gear, Bevel Gear, Rack;

4. Shaft Locking Device: could be alternative for Ringfeder, Sati, Chiaravalli, Tollok, etc.;

5. Shaft Coupling: including Miniature couplings, Curved tooth coupling, Chain coupling, HRC coupling,

Normex coupling, Type coupling, GE Coupling, torque limiter, Universal Joint;

6. Shaft Collars: including Setscrew Type, Single Split and Double Splits;

7. Gear & Rack: Spur gear/rack, bevel gear, helical gear/rack.

8. Other customized Machining Parts according to drawings (OEM) Forging, Casting, Stamping Parts.

PACKING

| Packaging | |

| Packing

|

We use standard export wooden case, carton and pallet, but we can also pack it as per your special requirements. |

OUR COMPANY

ZheJiang Mighty Machinery Co., Ltd. specializes in offering best service and the most competitive price for our customer.

After over 10 years’ hard work, MIGHTY’s business has grown rapidly and become an important partner for oversea clients in the industrial field and become a holding company for 3 manufacturing factories.

MIGHTY’s products have obtained reputation of domestic and oversea customers with taking advantage of technology, management, quality and very competitive price.

Your satisfaction is the biggest motivation for our work, choose us to get high quality products and best service.

OUR FACTORY

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit.To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Identifying Wear or Deterioration in Helical Couplings

Over time, helical couplings may experience wear or deterioration that can affect their performance. Here are signs to watch for and ways to identify them:

- Vibration: Increased vibration or unusual vibrations during operation can indicate misalignment or wear in the coupling.

- Noise: Unusual clicking, rattling, or squeaking noises during operation can point to worn or damaged coupling components.

- Reduced Performance: If the machinery’s performance declines or becomes less precise, it may be due to wear in the coupling affecting torque transmission.

- Excessive Heat: If the coupling becomes unusually hot during operation, it could indicate friction or misalignment issues.

- Visual Inspection: Regularly inspect the coupling for visible signs of wear, such as worn or deformed parts, cracks, or corrosion.

- Measurement: Use precision instruments to measure coupling dimensions and check for dimensional changes, which could indicate wear or deformation.

It’s essential to regularly inspect and maintain helical couplings to ensure their optimal performance and prevent potential issues.

Advantages of Using Helical Couplings in Industrial Applications

Helical couplings offer several key advantages when used in industrial applications:

- Misalignment Compensation: Helical couplings can accommodate angular, axial, and parallel misalignments between shafts, helping to extend the lifespan of connected components and reducing the risk of premature failure.

- High Torque Transmission: These couplings are designed to transmit high levels of torque between shafts, making them suitable for applications that require efficient power transmission.

- Backlash Reduction: The helical design minimizes backlash, ensuring accurate positioning and motion control in precision applications.

- Shock and Vibration Absorption: Helical couplings absorb shocks and vibrations, protecting connected equipment from excessive wear and minimizing noise in the system.

- Compact and Lightweight: The compact and lightweight design of helical couplings makes them ideal for applications with limited space and weight constraints.

- Easy Installation: Helical couplings are relatively simple to install, requiring minimal tools and expertise.

- Corrosion Resistance: Many helical couplings are made from materials that offer corrosion resistance, making them suitable for various environmental conditions.

- Cost-Effective: Helical couplings provide a cost-effective solution for flexible shaft connections, reducing the need for complex and expensive alignment procedures.

- Long Service Life: Properly installed and maintained helical couplings can have a long service life, contributing to the reliability of the overall system.

Overall, helical couplings are a versatile and reliable choice for industrial applications that require torque transmission, misalignment compensation, and vibration reduction.

Best Practices for Lubricating and Preserving the Performance of Helical Couplings

Lubrication is crucial for maintaining the performance and longevity of helical couplings. Here are some best practices to consider:

- Choose the Right Lubricant: Select a lubricant that is compatible with the materials of the coupling and provides adequate protection against wear and corrosion.

- Regular Lubrication: Follow the manufacturer’s guidelines for lubrication intervals. Regularly lubricate the coupling to ensure proper operation and prevent excessive wear.

- Clean Before Lubrication: Clean the coupling and the surrounding area before applying lubricant to prevent contamination.

- Apply the Right Amount: Apply the appropriate amount of lubricant as recommended by the manufacturer. Too much lubricant can lead to excess buildup and attract debris.

- Distribute Evenly: Ensure that the lubricant is evenly distributed across the coupling’s surfaces to provide effective lubrication.

- Monitor Performance: Regularly monitor the coupling’s performance for any signs of increased friction or abnormal operation that may indicate the need for relubrication.

- Inspect for Wear: During maintenance checks, inspect the coupling for signs of wear, corrosion, or damage. Replace the coupling if necessary.

- Protect Against Contaminants: Shield the coupling from dust, dirt, and other contaminants that can degrade the lubricant and cause premature wear.

- Environmental Considerations: If the machinery operates in extreme temperatures, wet or corrosive environments, choose a lubricant that can withstand these conditions.

- Follow Manufacturer’s Recommendations: Always follow the manufacturer’s recommendations for lubrication, maintenance, and storage to ensure optimal coupling performance.

By adhering to these best practices, you can maximize the efficiency, reliability, and lifespan of helical couplings in various mechanical systems.

editor by CX 2024-02-15

China supplier Original Excavator Parts Coupling CF-a Series Rubber Flexible Torsionally Steel Universal Shaft Coupling for Centaflex

Product Description

Original Excavator Parts Coupling CF-a Series Rubber Flexible Torsionally Steel Universal Shaft Coupling for Centafle

Product Display:

| Model | Outer Diameter(mm) | Inner Diameter(mm) | Hight(mm) | Diameter from Hole to Hole(mm) | Weight(kg) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4A/4AS | 103 | 53 | 28 | 68 | 0.18 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8A/8AS | 134 | 71 | 32 | 88 | 0.26 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16A/16AS | 160 | 80 | 41 | 110 | 0.54 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22A/22AS | 165 | 86 | 41 | 128 | 0.66 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25A/25AS | 183 | 102 | 46 | 123 | 0.78 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 28A/AS | 0.88 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30A/30AS | 213 | 117 | 57 | 145 | 1.28 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50A/50AS | 220 | 123 | 57 | 165 | 1.48 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80A/80As | 225 | 120 | 65 | 167 | 1.92 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 90A/90As | 278 | 148 | 70 | 190 | 3.1 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 140A/140AS | 285 | 151 | 71 | 215 | 3.42 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 250A/250AS | 6.6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 284B | 6.34 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4, 4655134, EX3, ZAX460MTH, ZAX480MTH, 4636444, ZX470-3, EX470, ZAX470, ZAX450-3, ZAX450-3F, ZAX5, Atlas Copco,,

AC 385, AC 396, AC415, AC416, AC 455, AC485, AC 486, AC86, AC836, AC976, AC 6-712, 4DNV98 Chinese Brand Excavators: LGK: 6085, 200 CLG 60, 205, 220, 906, 907, 908, 920, 925, 936, CLG906C, CLG922LG YC50-8, YC60-8, YC60-8, YC135-8, YC230, YC230-8, YC230LC-8, YC360, YC85, YC50, YC85-7, YC60-7, YC135 SW50, 60, 70, 150 FR85-7, FR65, FR80, FR150-7, ZL 60, 205, 230, 360 SY55, SY60, SY215, SY230, SY210, SY220, SY310 /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Applications of Helical Couplings in Various IndustriesHelical couplings find wide use in numerous industries and applications due to their versatility, reliability, and ability to handle misalignment and transmit torque:

The broad range of applications highlights the adaptability and reliability of helical couplings across various industries.

Utilization of Helical Couplings in Mechanical SystemsA helical coupling, also known as a beam coupling, is a type of flexible coupling that is used in mechanical systems to transmit torque and motion between shafts while accommodating misalignment. Here’s how it is utilized: Helical couplings consist of two hubs, each with helical slots that interlock with the other hub’s slots. The interlocking design allows for flexibility in multiple directions while maintaining torsional rigidity. When utilized in mechanical systems:

In summary, helical couplings provide an effective solution for transmitting torque and motion between shafts while accommodating misalignment and reducing vibrations in various mechanical systems.

Diagnosing and Addressing Issues with Helical Couplings in Machinery SystemsDiagnosing and addressing issues related to helical couplings in machinery systems require a systematic approach:

By conducting regular inspections, monitoring performance, and addressing issues promptly, you can maintain the optimal functioning of helical couplings in your machinery systems.

China supplier CNC Motor Helical Shaft Coupler Beam Coupling Connect EncoderProduct Description

A beam coupling, also known as helical coupling, is a flexible coupling for transmitting torque between 2 shafts while allowing for angular misalignment, parallel offset and even axial motion, of 1 shaft relative to the other. This design utilizes a single piece of material and becomes flexible by removal of material along a spiral path resulting in a curved flexible beam of helical shape. Since it is made from a single piece of material, the Beam Style coupling does not exhibit thebacklash found in some multi-piece couplings. Another advantage of being an all machined coupling is the possibility to incorporate features into the final product while still keep the single piece integrity. Changes to the lead of the helical beam provide changes to misalignment capabilities as well as other performance characteristics such as torque capacity and torsional stiffness. It is even possible to have multiple starts within the same helix. The material used to manufacture the beam coupling also affects its performance and suitability for specific applications such as food, medical and aerospace. Materials are typically aluminum alloy and stainless steel, but they can also be made in acetal, maraging steel and titanium. The most common applications are attaching encoders to shafts and motion control for robotics. Please contact us to learn more.

Applications of Helical Couplings in Various IndustriesHelical couplings find wide use in numerous industries and applications due to their versatility, reliability, and ability to handle misalignment and transmit torque:

The broad range of applications highlights the adaptability and reliability of helical couplings across various industries.

Advantages of Using Helical Couplings in Industrial ApplicationsHelical couplings offer several key advantages when used in industrial applications:

Overall, helical couplings are a versatile and reliable choice for industrial applications that require torque transmission, misalignment compensation, and vibration reduction.

Recent Advancements in Helical Coupling TechnologyRecent years have seen several advancements and innovations in helical coupling technology, aimed at improving performance, reliability, and ease of use:

These advancements continue to make helical couplings a reliable and versatile choice for a wide range of mechanical systems across industries.

China supplier Helical Drive Flexible Coupling for Encoder Shaft Coupling DimensionsProduct Description

Helical Drive Flexible Coupling For Encoder Shaft Coupling Dimensions Coupling refers to a device that connects 2 shafts or shafts and rotating parts, rotates together during the transmission of motion and power, and does not disengage under normal conditions. Sometimes it is also used

Couplings can be divided into rigid couplings and flexible couplings. Rigid couplings do not have buffering property and the ability to compensate the relative displacement of 2 axes. It is required that the 2 axes be strictly aligned. However, such couplings are simple in structure, low in manufacturing cost, convenient in assembly and disassembly, and maintenance, which can ensure that the 2 axes are relatively neutral, have large transmission torque, and are widely used. Commonly used are flange coupling, sleeve coupling and jacket coupling. Flexible coupling can also be divided into flexible coupling without elastic element and flexible coupling with elastic element. The former type only has the ability to compensate the relative displacement of 2 axes, but cannot cushion and reduce vibration. Common types include slider coupling, gear coupling, universal coupling and chain coupling; The latter type contains elastic elements. In addition to the ability to compensate the relative displacement Our leading mainly including universal couplings, drum gear couplings, elastic couplings etc.

Coupling performance

Inspection equipment: How to select the appropriate coupling type Q: Do you provide OEM Service? Q: Do you provide customized machining parts? Q: What is your payment term? If there’s anything we can help, please feel free to contact with us.

Endurance of Helical Couplings for High Torque and Axial MotionHelical couplings are designed to withstand a range of mechanical forces, including high levels of torque and axial motion:

Engineers select helical couplings based on the anticipated torque requirements and axial motion characteristics of the application. It’s important to ensure that the selected coupling has the necessary torque rating and axial flexibility to meet the demands of the specific machinery or system.

Utilization of Helical Couplings in Mechanical SystemsA helical coupling, also known as a beam coupling, is a type of flexible coupling that is used in mechanical systems to transmit torque and motion between shafts while accommodating misalignment. Here’s how it is utilized: Helical couplings consist of two hubs, each with helical slots that interlock with the other hub’s slots. The interlocking design allows for flexibility in multiple directions while maintaining torsional rigidity. When utilized in mechanical systems:

In summary, helical couplings provide an effective solution for transmitting torque and motion between shafts while accommodating misalignment and reducing vibrations in various mechanical systems.

Specialized Maintenance Routines for Ensuring the Longevity of Helical CouplingsTo ensure the longevity of helical couplings, consider implementing specialized maintenance routines:

By following these specialized maintenance routines, you can maximize the longevity and performance of helical couplings in your machinery systems.

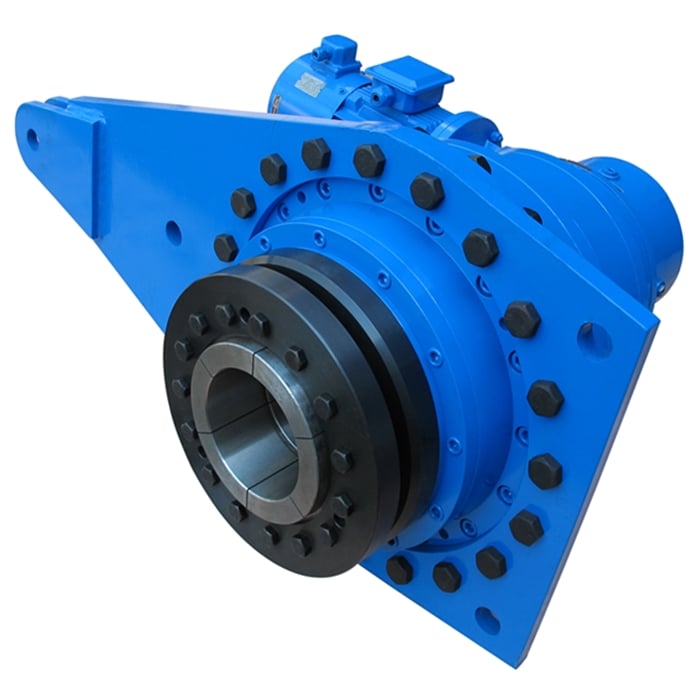

China manufacturer & factory supplier for XG in Perm Russian Federation suspension reducer shaft mounted gearbox for belt drive conveyor drive power transmission 2kd gearbox 90 degree gearbox With high quality best price & service

ISO 9001:2000 certified. Stocking distributor of energy transmission goods like roller & multiple strand roller chains. Items also consist of brakes, generate elements, gears, torque limiters, U-joints, pulleys, sheaves, encoders, belt drives, clutches & motors are also offered.Our solution variety also addresses locking assemblies (clamping elements/locking gadget), taper bushes, QD bushes, bolt-on hubs, pto shaft, agricultural gearboxes,torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, universal joint, rod finishes and yokes.

Overview

Fast Specifics

Our patented coupling mechanism C Line is the outcome of our information and improvement. It enables straightforward coupling and uncoupling of the PTO push shaft. The cover delivers the consumer much more comfort simply because of its ergonomically and compact kind. The users’ protection is assured, since he can not get entangled in protruding parts of the yoke. There is also significantly less grime present at handling and there are much less problems related with it.

Provide Capability

Packaging & Shipping and delivery

On the internet CustomizationTo address these sealing and efficiency concerns, Emerson Electrical power Transmission (EPT) developed several layout and producing recommendations. The ensuing gearboxes are likely to run cooler and leak totally free, when compared with conventional worm equipment units.

Specification

XG suspension reducer shaft mounted gearboAdhering to “Survival by High quality, Improvement by Engineering & Credit”, The firm will constantly improve merchandise performance to meet the rising buyer specifications in the arduous fashion of operate. x for belt drive conveyor

Conveyor & Substance Managing Mining & Quarry

Certifications

trade demonstrate

Packing

Top quality management

Business info

Delivery

Speak to us

Best China manufacturer & factory china supplier K series solid shaft reversing rolls speed reducer With high quality best price

we offer one-stop solution for the purchase of mechanical chain,power transmission parts and pto shaft, agricultural gearboxes products EPG Machinery is located in XiHu Area HangZhou Zhejiang ,China. It is 30km from our factory to HangZhou international airport. in China.

Overview

Quick Details

Packaging & Delivery

Online Customization

Product Description

PROFESSIONAL MANUFACTURE —— SINCE 1995

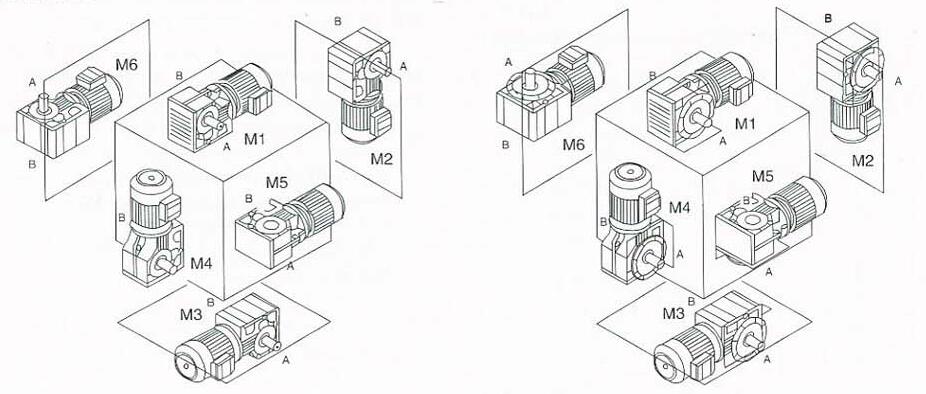

K series Spiral Bevel Gear Reducer Hard Tooth Sureface Gear/Electric Motor Speed Reducer with reduction gear R K F S series spiral bevel gear box tractor pto reverse gearbox for buggy K series solid shaft reversing rolls speed reducer Chinese electric motor speed reducer is widely used in mining machinery, chemical industry,steel metallurgy, light industry,environmental protection, paper making, printing, lifting transport, food industry and so on. Main Series Product: R series helical gear reducer, K series spiral bevel gear reducer, NGW, P series planetary reducer, H B series gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gear reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer, etc. Meanwhile, map sample processing business can be undertaken. K Series Electric Motor Speed Reducer Gearbox Designed on the basis of modular combined system,the gear reducer have abundant combinations of motor,mounting position and structure projects,the classifying class of transmission ratio is detailed,which is suitable for different working situation and realize mechatronics.

Specification K series solid shaft reversing rolls speed reducer: (please contact us for more types & model)

Model selection: Closely using the ideal reduction ratio. Reduction ratio = servo motor speed / reducer output shaft speed Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer. The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide. K series solid shaft reversing rolls speed reducer. Company Information Established in 1995 , HangZhou Ever-Power Machinery is a professional manufacturer and exporter that is concerned with the design, development and production of Gearbox Speed Reducer. We are located in HangZhou of ZheJiang Province, with convenient transportation access. With our own brand “EPG”, all of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world. Our company possesses complete machining center, lathe, gear shaping machine, gear milling machine, gear grinding machine and assembling lines. Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction.

Technology

Our Services Electric Motor Speed Reducer gearbox is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm gearbox, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products. Electric Motor R K F S series spiral bevel gear box tractor pto reverse gearbox for buggy. Packaging & Shipping

FAQ 1.Q:Are you the factory or trading company? A:We are the professional Factory with over 20 years of experience.

2.Q:Can you customize according to our requirements? A:Yes, we can design nonstandard products according to customer’s drawing and sample.

3.Q:How long is the delivery date? A:10-20 working days.

4.Q:Where is your factory? A:We are in HangZhou of ZheJiang Province, you can get here by high speed train or fly to Jinan. Welcome to visit us!

5.Q:What’s your payment terms? A:TT 30% as deposite, 70% banlance paid before delivery.

Wh78 China rav4 drive shaft replacement cost Welded Steel Chain Hardware Supplier with ISO9001 with ce certificate top quality low priceWe – EPG Team the largest agricultural gearbox and pto manufacturing unit in China with 5 different branches. For far more specifics: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

Because its institution, the company has constantly adhered to the mission of “Striving to be a leader in the industry”, Get-Win cooperation, Collaborative Innovation, High quality initial and Buyer very first are the main values of the business. Motivated by the mission and values of the company, we supply bets support to all consumers and distributors. At any time-power specialist in creating all sorts of mechanical transmission and hydraulic transmission like: planetary gearboxes, worm reducers, in-line helical equipment velocity reducers, parallel shaft helical gear reducers, helical bevel reducers, helical worm equipment reducers, agricultural gearboxes, tractor gearboxes, auto gearboxes, pto travel shafts, EPT reducer & relevant gear elements and other relevant products, sprockets, hydraulic method, vaccum pumps, fluid coupling, equipment racks, chains, timing pulleys, udl speed variators, v pulleys, hydraulic cylinder, gear pumps, screw air compressors, shaft collars low backlash worm reducers and so on. moreover, we can create tailored variators, geared motors, electrical motors and other hydraulic items according to customers’ drawings.

Top China Brand In China Factory Made Mitsubishi Pajero Drive Shaft – Supplier Manufacturer wholesaler FactoryFor much more information.: Cell/Whatpp: +8613083988828 The quality of items is for us and for our buyers of substantial significance. This is why we use European made parts in our merchandise. We also execute constant manage of incoming materials and the handle of finished merchandise. In our business we work in accordance to ISO 9001.Our variety of gearboxes is divided into the following types: 1. General Goal packing containers. Normal variety of “T” or “L” configuration gearboxes appropriate for a wide variety of apps.Our products are applied in a lot of fields.Our goods is common exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Center and South The united states, Thailand, Pakistan, Indonesia, much more than sixty nations and areas.

Overview

Quick Details

Provide Capability

Packaging & Shipping and delivery

On-line Customization

Merchandise Data

Solution Information

PTO Shaft

The energy take-off (PTO) is a innovative mechanism, permitting implements to attract vitality from the motor and transmit it to yet another software. It functions as a mechanical gearbox which can be mounted on the vehicle’s transmission. The power consider-off shaft (PTO shaft) is a critical element, designed and produced for steady hefty-obligation use. A very good PTO shaft need to be sturdy sufficient to bear the torsion and shear tension and decrease vibration. Setforge, the forging subsidiary of Ever-Electrical power Team, manufactures chilly extruded PTO shafts for all sorts of agriculture automobiles. Our PTO shafts offer excellent dependability and sturdiness during every day use. EP Group has been internationally identified as a reliable world-wide provider. Our condition-of-the-art production procedure and skilled engineers make certain the top-top quality of all Farinia components.

Merchandise Screen

Merchandise Show

12″ Rock Auger 6″ Rock Auger PTO drive shaft Hello … CompanyInfo

Firm Profile

Ever-Energy Group

EPG have higher-tech machinery and test gear. We can make planet course high precision merchandise. Certifications

Certifications

Shipment & Payment

Our Rewards

A: Your inquiry relevant to our products or prices will be replied in 24 hours. faq

FAQ

one) How can I area get?

two) How can I spend you?

…… EPG – one of the biggest transmission manufacturing unit in China, main goods: worm geared motors, agricultrual gearbox, planetary equipment travel, helical,screw, beve gears and spare parts and agricultural elements manunfacuter in China /For a lot more details.: Cell/Whatpp: +8613083988828

Agricultural China PTO Shaft – Supplier Manufacturer wholesaler Factory

For far more data.: Cell/Whatpp: +8613083988828 Cat three Level Hitch How do I function the PTO on my tractor? Prior to working the PTO, you will need to have your tractor to get to the commencing RPM (revolutions for every moment). After the commencing RPM has been attained you can commence operating the PTO.We have built a huge infrastructural device equipped with innovative engineering devices for creating an unparalleled selection of items, which are in compliance with the industry specifications and the commonplace market place traits. EPG is 1 of the most significant producers in China. We have sophisticated machines for generation and new technologies tests capacity . Through adopting new technological innovation from British, German, U.S.A, our merchandise are very best sellers all more than European, America, and Southeast Asia.Our items are marketing effectively in Chinese markets and some merchandise bought in intercontinental markets are effectively acquired by Chinese and international clients at residence and overseas.

Overview

Fast Information

Provide Capacity

Packaging & Shipping

On the internet Customization

Product Description

Agricultural PTO Generate Shaft

HZPT Group supply a extremely massive variety of spare components, necessary by the end consumer for the regimen routine maintenance of the PTO shafts, that need to be executed at the very least once a week.

The areas of the PTO shafts that are most topic to use are: the safety guards

HZPT Team has a large stock of any spare elements for the PTO shafts, this kind of as: cross joints

Note: Damaged, ruined or badly fitting guards can be just as dangerous as no guard at all.

Relevant Goods

Our Business

At any time-power is specialist in making all sorts of mechanical transmission and hydraulic transmission like: planetary gearboxes, worm gearboxes, in-line helical gear speed gearboxes, parallel shaft helical equipment gearboxes, helical bevel gearboxes, helical worm gear gearboxes, agricultural gearboxes, tractor gearboxes, car gearboxes, pto travel shafts, specific gearbox & relevant gear parts and other related items, sprockets, hydraulic method, vaccum pumps, fluid coupling, equipment racks, chains, timing pulleys, udl pace variators, v pulleys, hydraulic cylinder, equipment pumps, screw air compressors, shaft collars low backlash worm gearboxes and so on. furthermore, we can produce tailored variators, geared motors, electric powered motors and other hydraulic goods according to customers’ drawings. We offers a trustworthy gurantee for the product’ s quality by advanced inspection and testing products. specialist technical group, exquisite processing technological innovation and rigorous management program. In latest many years, the firm has been creating swiftly by its prosperous knowledge in production, adcanced managemant system , standardized administration program, strong specialized force. We constantly adhere the concept of survial by top quality, and decelopment by innovation in science and engineering. At any time-electricity is ready to operate with you hand in hand and develop brilliance collectively!

Grinding Workshop

CNC Tooth Device

CNC Lathe Workshop

Figuring Middle

CNC Workshop

Warmth Therapy Machine

3D Measurement Equipment

Gear Enamel Profile Examination Devices

Heat Therapy Workshop

Tooth Profile Workshop

Materials available

Low carbon steel, C45, 20CrMnTi, 42CrMo, 40Cr, stainless steel. Can be adapted relating to customer demands.

Surface area therapy

Blacking, galvanization, chroming, electrophoresis, colour painting, …

Warmth treatment method

Large frequency quenching warmth treatment method, hardened teeth, carbonizing, nitride, … Certifications

FAQ

Q: Are you buying and selling organization or producer ? Q: Do you provide samples ? is it totally free or added ? Q: How long is your supply time ? What is your conditions of payment ? Q: What is the exact MOQ or price for your product ? If you have an additional concern, remember to truly feel totally free to make contact with us. Packing & Shipping and delivery

Solutions

Also I would like to get this prospect to give a short introduction of our Ever-Electrical power organization: Our firm is a famous maker of agriculture gearbox,worm lessen gearbox, PTO shafts, Sprockets ,rollar chains, bevel equipment, pulleys and racks in china . We have exported several goods to our consumers all over the globe, we have extended-time experience and sturdy technologies help. Some of our buyer : -Ø Our Company with in excess of twelve year’s historical past and a thousand personnel and 20 income. you also can check our internet site to know for much more specifics, if you require our merchandise catalogue, remember to speak to with us.

EPG – 1 of the largest transmission factory in China, primary items: worm geared motors, agricultrual gearbox, planetary equipment drive, helical,screw, beve gears and spare areas and agricultural parts manunfacuter in China /For more information.: Cellular/Whatpp: +8613083988828

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||