we offer one-stop solution for the purchase of mechanical chain,power transmission parts and pto shaft, agricultural gearboxes products EPG Machinery is located in XiHu Area HangZhou Zhejiang ,China. It is 30km from our factory to HangZhou international airport. in China.

Overview

Quick Details

-

Applicable Industries:

-

Manufacturing Plant

-

Pole:

-

three stage four stage six Stage

-

Ratio:

-

7.96-16978

-

Housing Material:

-

Cast Iron

-

Working temperature:

-

-40~45℃

-

Application:

-

mining, chemical industry,steel metallurgy,lifting transpor and ect.

-

Process:

-

Carburizing, Nitriding , Grinding

-

Efficiency:

-

94%~98%

-

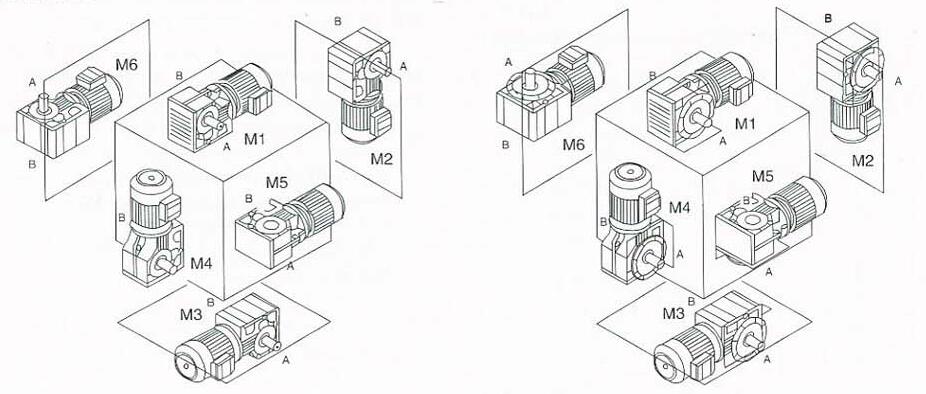

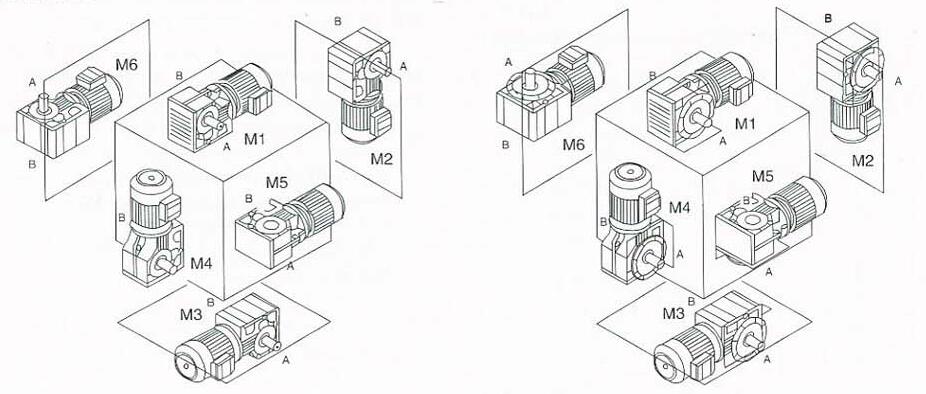

Mounting Position:

-

Horizontal,Vertical,Flange

-

Color:

-

Blue,Green,Gray,Red

-

Type:

-

K series solPTO Shaft Safety Tips The most common PTO related injuries tend to occur when articles of loose clothing become entangled in the shaft. When operating the PTO, never reach over the shaft for any reason and avoid wearing loose-fitting clothing. Injury can occur quickly, providing the operator little time to react, and in some cases resulting in death.id shaft reversing rolls speed reducer

Packaging & Delivery

-

Lead Time

:

-

| Quantity(Bags) |

1 – 20 |

>20 |

| Est. Time(days) |

15 |

To be negotiated |

Online Customization

Product Description

PROFESSIONAL MANUFACTURE

—— SINCE 1995

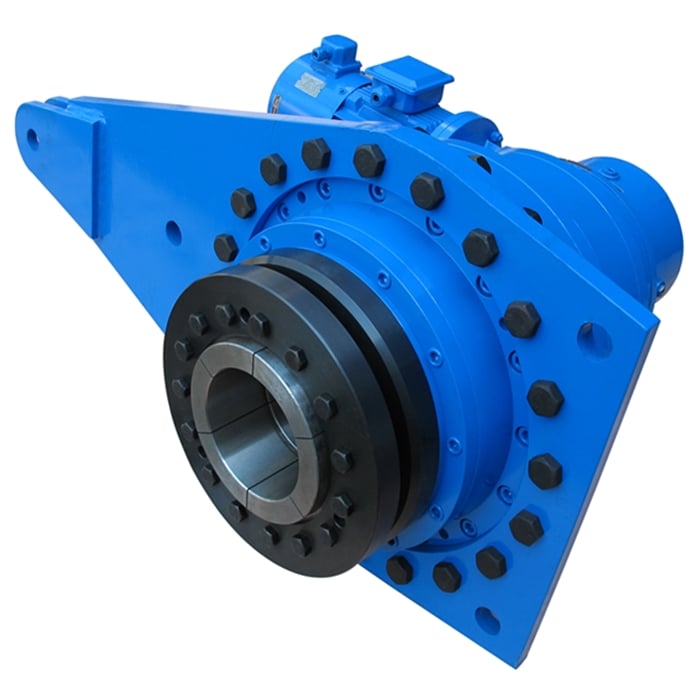

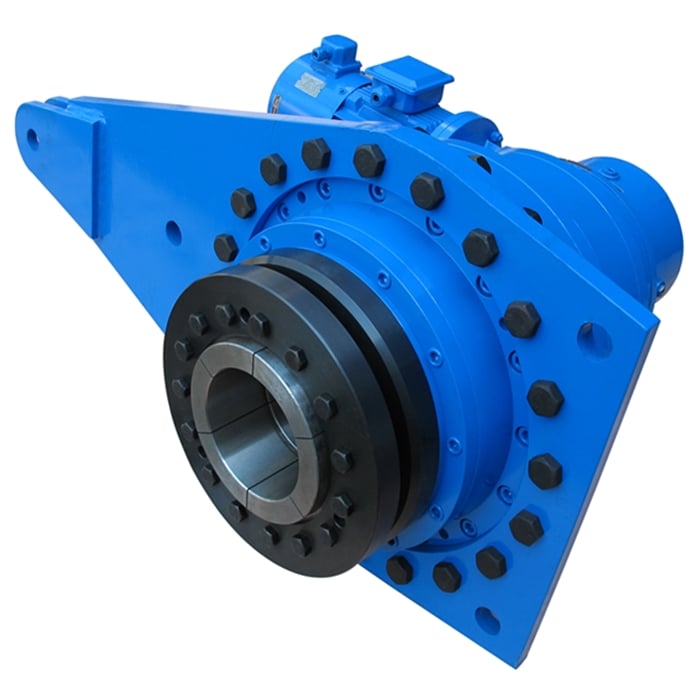

K series Spiral Bevel Gear Reducer

Hard Tooth Sureface Gear/Electric Motor Speed Reducer with reduction gear

R K F S series spiral bevel gear box tractor pto reverse gearbox for buggy

K series solid shaft reversing rolls speed reducer

Chinese electric motor speed reducer is widely used in mining machinery, chemical industry,steel metallurgy, light industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

Main Series Product: R series helical gear reducer, K series spiral bevel gear reducer, NGW, P series planetary reducer, H B series gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gear reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer, etc. Meanwhile, map sample processing business can be undertaken.

K Series Electric Motor Speed Reducer Gearbox Designed on the basis of modular combined system,the gear reducer have abundant combinations of motor,mounting position and structure projects,the classifying class of transmission ratio is detailed,which is suitable for different working situation and realize mechatronics.

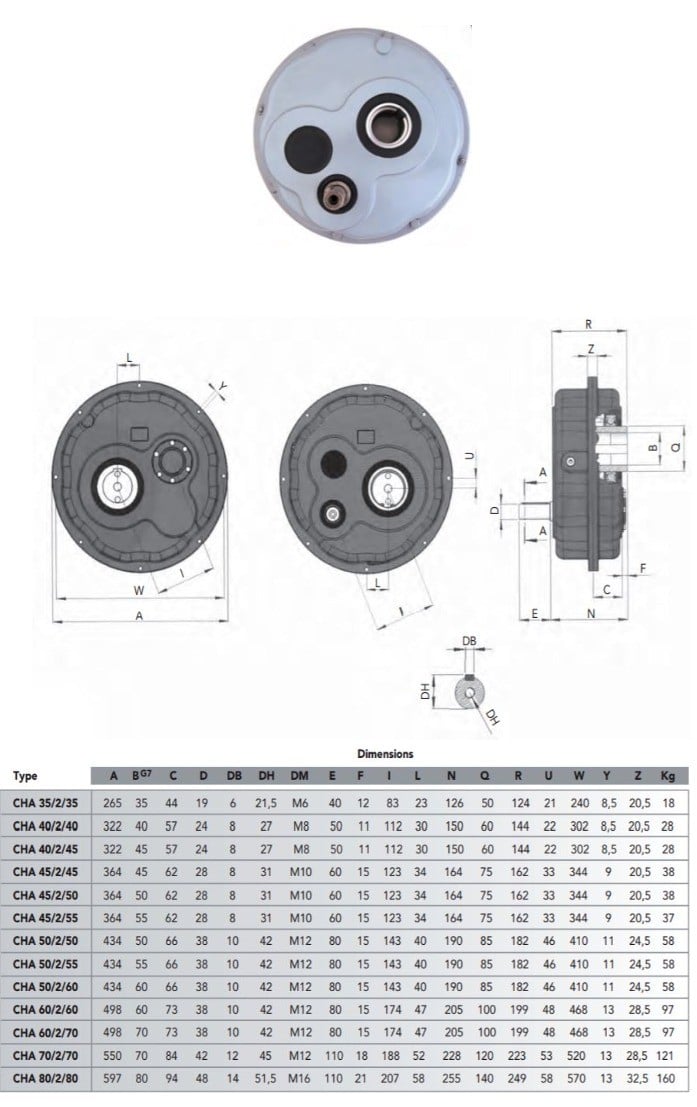

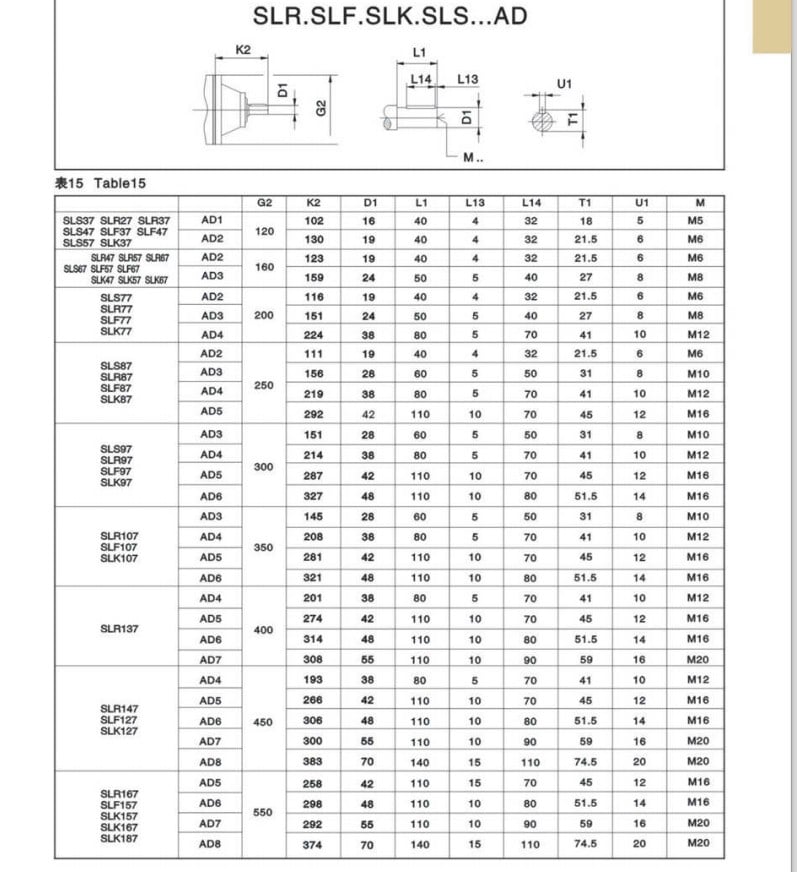

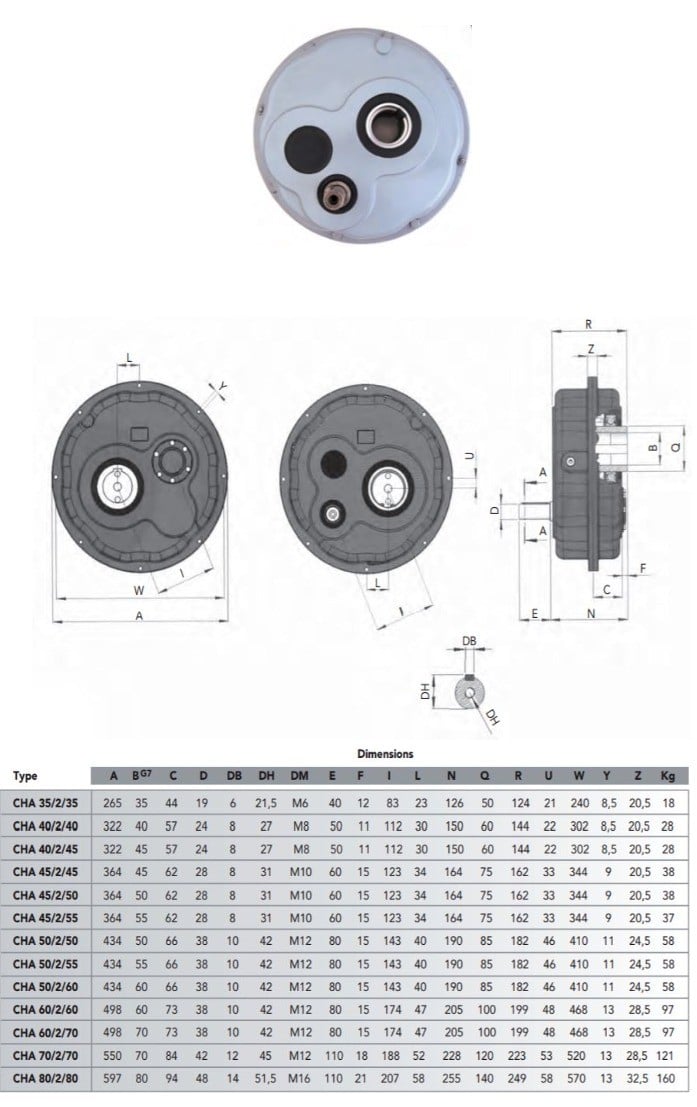

Specification

K series solid shaft reversing rolls speed reducer:

(please contact us for more types & model)

| K Series Specification |

| Size |

37 |

47 |

57 |

67 |

77 |

87 |

97 |

107 |

127 |

157 |

167 |

187 |

| Structure |

K KA KF KAF KAZ KAT KAB |

Input power

rating(kw) |

0.18-3.0 |

0.18-3.0 |

0.18-5.5 |

0.18-5.5 |

0.37-11 |

0.75-22 |

1.1-30 |

3-45 |

7.5-90 |

11-160 |

11-200 |

18.5-200 |

| Ratio |

5.36-106.38 |

5.81-131.87 |

6.57-145.14 |

7.14-144.79 |

7.24-192.18 |

7.19-197.37 |

8.95-176.05 |

8.74-141.46 |

8.68-146.07 |

12.65-150.41 |

17.28-163.91 |

17.27-180.78 |

Permissible torque

N.m |

200 |

400 |

600 |

820 |

1550 |

2700 |

4300 |

8000 |

13000 |

18000 |

32000 |

50000 |

Model selection:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide. K series solid shaft reversing rolls speed reducer.

Company Information

Established in 1995 , HangZhou Ever-Power Machinery is a professional manufacturer and exporter that is concerned with the design, development and production of Gearbox Speed Reducer. We are located in HangZhou of ZheJiang Province, with convenient transportation access. With our own brand “EPG”, all of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Our company possesses complete machining center, lathe, gear shaping machine, gear milling machine, gear grinding machine and assembling lines. Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction.

Technology

- 1. Big Volecity- Reducing Ratio:Ratio of single-stage speed-reducing is 1/11-1/87; Ratio of double stage speed-reducing is 1/112-1/5133;Ratio of three-stage speed-reducing is 1/2057-1/446571;more-stages can be combined according to the requirement.Industrial 5: 1 ratio gearbox reduction gearbox prices for bucket conveyor.

-

2. High driving efficiency:Due to adopting rolling engagement in falling-in part, the driving efficiency can reach above 90%.3Worm Gear reducers are utilized in power transmission applications requiring high ratio speed reduction in a limited space. The gears are used on right angle, non-intersecting shafts. When properly aligned, worms and worm gears are the quietest and smoothest form of gearing. One drawback of worm gearing is as the ratio of this gearing increase, the efficiency of the gearing decreases. A worm gear reducer is a right angle speed reducer that allows the maximum speed reduction in the smallest package.: 1 ratio reduction gearbox prices for belt conveyor.

-

3. Small in size, light weight: with compacted structure,small size and light weight. Due to adopting the principle of planet driving so that the input and output shaft in the same axis which will integrated with the motor.

-

4. Long service life: Has good resistance to abrasion because the main driving engaging parts are made of bearing steel and applying rolling friction.Hypoid Gearing Arrangement gearbox prices for steel and iron industry.

-

5. Stable running: for most driving procedure, we adopt multi-teeth falling-in. Then the running will be stable with low noise.Electric Motor Speed Reducer with reduction gear for conveyor and production line.

-

6. Convenient dismounting:reasonable structure and design.

-

7. Strong overloading ability,anti-compact,suitable for frequently start and double-side rotation.

Our Services

Electric Motor Speed Reducer gearbox is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm gearbox, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products. Electric Motor R K F S series spiral bevel gear box tractor pto reverse gearbox for buggy.

Packaging & Shipping

FAQ

1.Q:Are you the factory or trading company?

A:We are the professional Factory with over 20 years of experience.

2.Q:Can you customize according to our requirements?

A:Yes, we can design nonstandard products according to customer’s drawing and sample.

3.Q:How long is the delivery date?

A:10-20 working days.

4.Q:Where is your factory?

A:We are in HangZhou of ZheJiang Province, you can get here by high speed train or fly to Jinan.

Welcome to visit us!

5.Q:What’s your payment terms?

A:TT 30% as deposite, 70% banlance paid before delivery.