The new products include a series of high-tech and high quality chains and sprockets and gears, such as chains and gearboxes for agricultural machineries, metallurgical chains, escalator step-chains, high-speed tooth chains, timing chains, self-lubrication chains, among which have type high speed tooth chain for car branch dynamic box and aerial chains fill in the blanks of chain in China.

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, Construction works , Energy & Mining, agricultural machiner

- Product name:

-

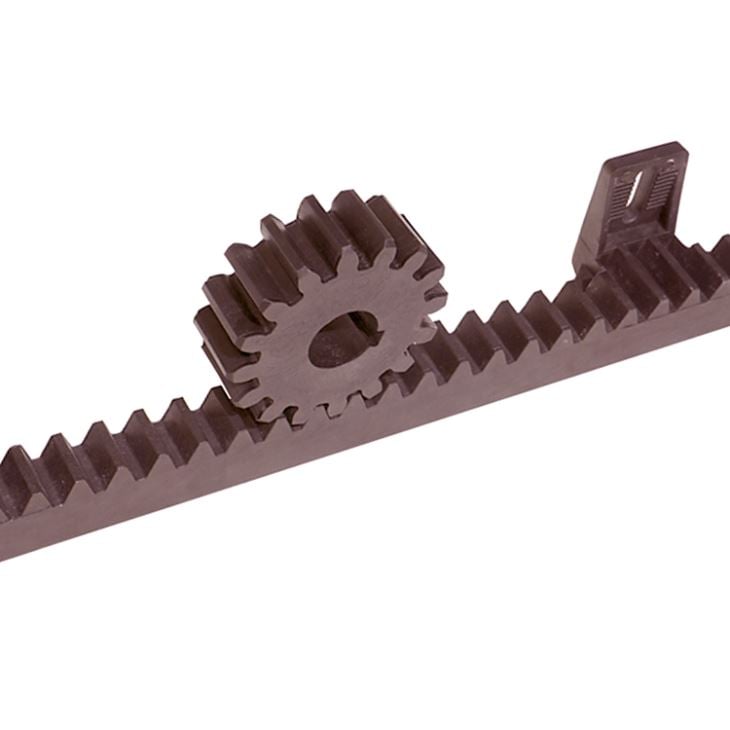

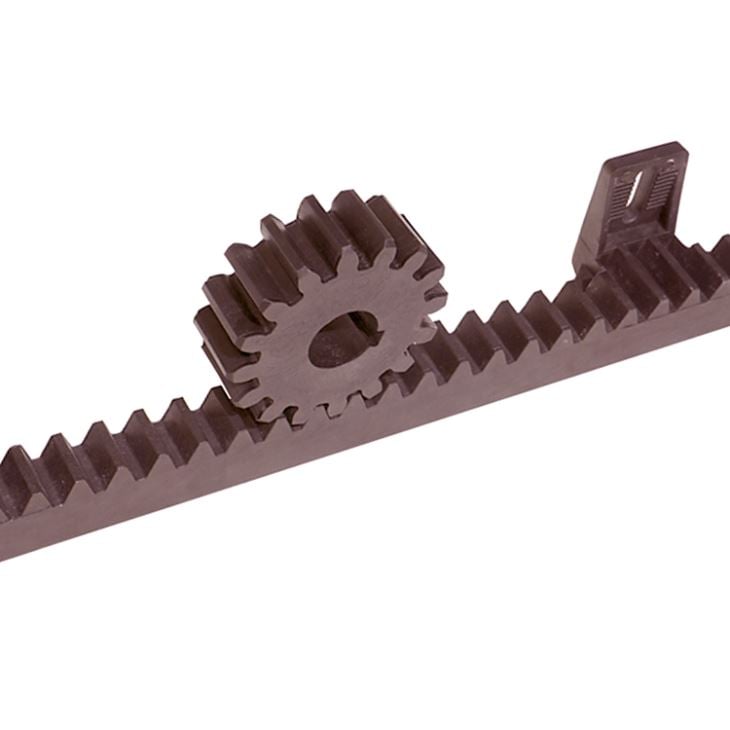

Module 1 Steel Helical Rack Pinion Gear

- Application:

-

Match with the gear rack

- Processing:

-

Hobbing

- Color:

-

Natural or black

- Pressure Angle:

-

20 Degree

- Precision:

-

DIN6/7/8/9/10

The EPG GROUP range of PTO shafts accessories includes various types of yokes for the connection of the tractor power take-off with recessed push button and/or ball collar and/or ball collar for constant velocity joints, with the following spline dimensions: 1”3/8 Z6 – 1”3/8 Z6 -1”3/8 Z21- 1”3/4 Z6- 1”3/4 Z20

- Type:

-

Helical teeth

- Our products are selling well in Chinese markets and some products sold in international markets are well received by Chinese and foreign clients at home and abroad. Surface treatment:

-

Black oxide/Teeth hardened

- Hub:

-

With hub or without hub

- MOQ:

-

5pcs

Supply Ability

- Supply Ability:

- 10000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Carton ,Wooden case or as your need

- Port

- Tianjin/Qingdao/Shanghai Port

-

Lead Time

: -

Quantity(Bags) 1 – 50 51 – 100 >100 Est. Time(days) 15 25 To be negotiated

Online Customization

Specification

|

High Precision Small Gear rack and Pinion Gears |

|

|

Module: |

M0.5-M10 |

|

Material: |

C45/1045/S45C/Stainless steel/Brass/Plastic/POM/Nylon |

|

Pressure angle: |

20 degree |

|

Precision grade: |

DIN6/DIN7/DIN8/DIN9/DIN10 |

|

Machining process: |

Hobbing, Milling, Drilling, Shaving, Grinding |

|

Heat treatment: |

Hardening and Tempering, High Frequency Quenching,Carburizing etc |

|

Surface treatment: |

Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

Product Show

Our Helical Gear

Many Types Gear

Different Materials Pinion Gear

Process

Packing

Usuallu used the suitable for transport by sea, rail, air, and other suitable for import and export customs clearance of free fumigation wooden box of free fumigation wooden pallets (precision products used the collision coating layer in the packaging box, to ensure the goods safe enough).

Remarks:

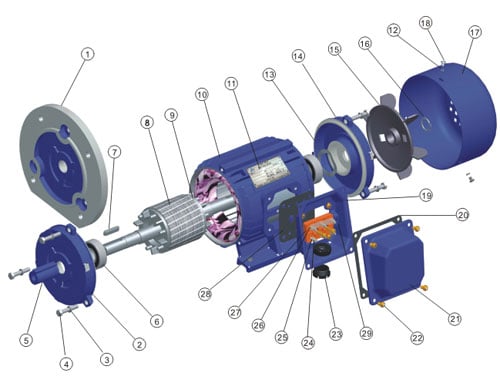

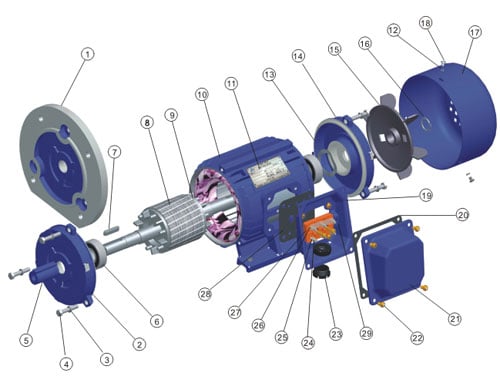

All items are checked and tested thoroughly during eveMachining of the gearbox To make a worm gearbox, first take a blank of an alloy. A bronze bearing is made in the center of the blank. The hobbing cutter is then used to reduce the diameter of the blank relative to the finished height of the tooth tip on the gear wheel, so the depth of the cut needs to be added to the blank’s diameter. The necessary threading tool is grind to cut the worm. The side clearance on the left-hand side of the cutter tip is allowed for the worm’s pitch angle. The best finish is put on the cutting tool using a slip stone. Gear blank is then mounted on a turntable that acts as a bearing support. This bearing support is mounted on the rear of the lathe cross-slide with the hobbing cutter mounted between the centers. The two worms are then machined, out of which one is made the cutter and finally the cutter is used to machine the worm gear.ry working procedure, and after the product is finally manufactured to ensure that the best quality product enter into the market.

Payment & Shipping

Our Other Products

Spur gear

Bevel gear

Gear rack

Sprocket

Timing pulley

Timing belt

Roller chain

Worm gear & shaft

Linear rail & block

Contact Us