We – EPG Team the bigge EPT Chain and agricultural gearbox manufacturing facility in China with 5 various branches. For much more particulars: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Solution specification

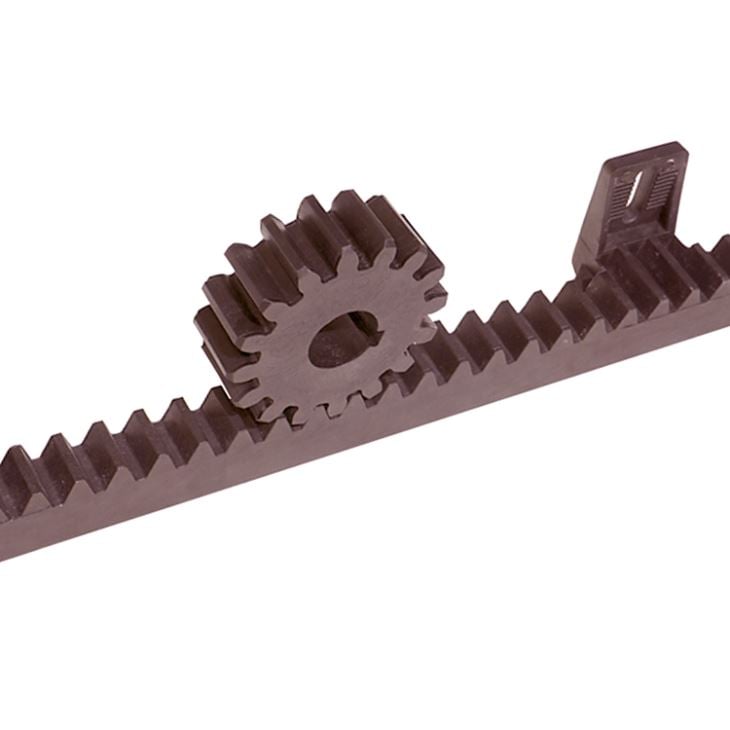

one.Substance:C forty five# metal ,stainless steel or EPT necessary supplies.

two.Gears can be made in accordance the customer’s drawings

three.Heat therapy: Hardening and Tempering, Large Frequency Quenching, Carburizing Quenching and so on in accordance the specifications..

four. Inspection: All items are checked and analyzed thoroughly in the course of each operating process and right after production will be reinspected.

About us

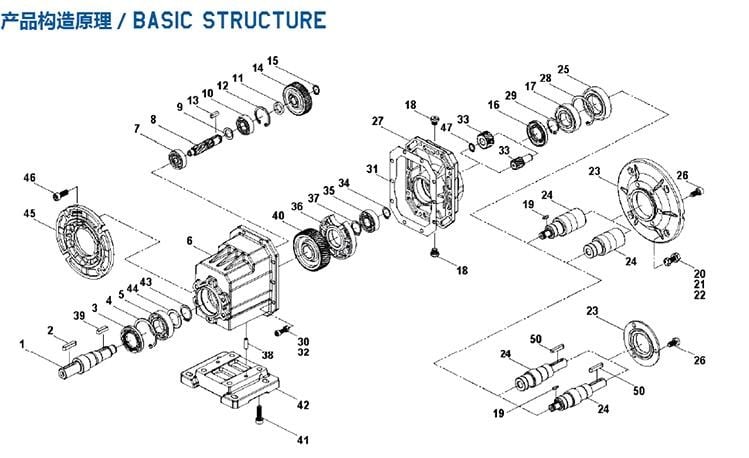

HangZhou EPT Sprocket Co., Ltd. is a specialist maker of numerous sprocket wheels, stainless steel sprocket wheels, non-regular sprocket wheels, big pitch sprocket wheels, coupling sprocket wheels, spur gears, timing belt wheels, gear racks, umbrella Gear, worm equipment, shaft, sleeve and EPT transmission parts producers. And according to consumer drawings, samples, dimension processing personalized manufacturing. The company integrates layout R & D, production and income. In accordance with rigorous generation, inspection and high quality specifications, the organization has established a thorough quality program, production procedure and best quality handle. The company’s sprocket merchandise are of substantial quality, balance and durability.

The business now has 80 sets of different high-precision CNC lathes, equipment hobbing devices, gear shapers, tempering furnaces, quenching gear, gantry planers, common milling, sawing machines, vertical broaching equipment, hydraulic machines and EPT processing tools, with an once-a-year generation potential of 2 million parts . Carburizing and quenching, nitriding, quenching and EPT warmth treatment method, area blackening, galvanizing, electrophoresis, etc. At the identical time, it also has substantial-precision screening gear this sort of as: Rockwell hardness tester, Vickers hardness tester, metallographic microscope, image measuring instrument, Magnetic particle flaw detectors, etc. The products made are widely used in metallurgy, steel, chemical, textile, agricultural machinery, a few-dimensional garages, packaging equipment, chemical machinery, pharmaceutical equipment, industrial and mining machinery and EPT industries. The product indicators meet up with the requirements of importing similar products and are exported to Hong Kong and ZheJiang , Southea EPT Asia, Europe, The usa, the Middle Ea EPT and EPT locations, and are deeply dependable and praised by clients.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How extended is your supply time?

A: Usually it is 5-ten days if the items are in inventory. or it is fifteen-twenty times if the items are not in inventory, it is in accordance to amount.

Q: Do you offer samples ? is it free or further ?

A: Of course, we could offer the sample for free of charge charge but do not pay out the co EPT of freight.

Q: What is your phrases of payment ?

A: Payment thirty%TT in advance. 70% T/T before shippment.

Q:What`s the MOQ of your goods?

A:1 established,we can also deal with the sample get. and the huge-quantity.

The use of authentic products manufacturer’s (OEM) part quantities or emblems , e.g. CASE® and John Deere® are for reference purposes only and for indicating merchandise use and compatibility. Our company and the shown replacement areas contained herein are not sponsored, accredited, or manufactured by the OEM.