EPG will always adhere to it enterprise spirit of being practical, innovative, efficient and excellent to make the top international transmission drive.

Overview

Quick Details

-

Applicable Industries:

-

Building Material Shops, Manufacturing Plant, farms

-

Brand Name:

-

OEM

-

Brand:

-

syf

-

Bore size:

-

200-1300 mm

-

Outside Diameter:

-

300-8000mm

-

Material:

-

50Mn/42CrMo/Customized

-

Warrantee:

-

1 year

-

OEM:

-

syf

-

Dimension:

-

390*654*85 mm

-

Weight:

-

98 KG

Supply Ability

-

Supply Ability:

- 1500 Set/Sets per Month

Packaging & Delivery

- Packaging Details

- 1. Bearing surface is covered with the anti-rust oil first; And then wrapped with the plastic film;

2. And then packed with Kraft paper and professional belts;

3. At last, with wooden box totally at the outer packing to in void the rust or the moist;

4. Packaging can be done according to customer’s requirements.”>HGB Packaging Details:

1. Bearing surface is covered with the anti-rust oil first; And then wrapped with the plastic film;

2. And then packed with Kraft paper and professional belts;

3. At last, with wooden box totally at the outer packing to in void the rust or the moist;

4. Packaging can be done according to customer’s requirements.

- Port

- China any Port

-

Lead Time

:

-

| Quantity(Bags) |

1 – 100 |

>100 |

| Est. Time(days) |

7 |

To be negotiated |

Online Customization

Why Choose Us

Product Description

1,Single row four point contact ball slewing bearing

2,Single row cross roller slewing bearing

3,Double-row ball slewing bearing

4,Three-row roller slewing bearing

5,Roller/Ball Combination Slewing bearing.

Single row four point

contact ball slewing bearing

Single row cross

roller slewing bearing

Double Row

Ball slewing bearing

Three row

roller slewing bearing

Roller/Ball Combination

Slewing bearing

|

Type

|

Single row four point contact ball slewing bearing

|

|

Rollng elements

|

Steel ball / CylindeOur company has solid economic strength, builds up a technician team contingent with high quality, possesses the production assembly line of technicalization in China and perfect system checking on product quality and runs marketing networks throughout the country. r Roller

|

|

Rollng elements Material

|

GCr5/GCr15SiMn/Customized

|

|

Bearing Material

|

50Mn/42CrMo/42CrMo4V /Customized

|

|

Cage Material

|

Nylon/ steel /copper

|

|

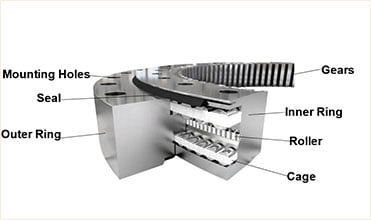

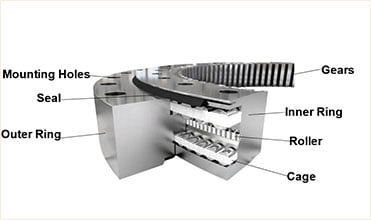

Structure

|

taper pin , Mounting holes,Inner ring ,grease fitting,load plug, seals , roller ,spacer balls or separators

|

|

Outer diameter

|

50-10000mm

|

|

Bore size

|

50-10000mm

|

|

Mounting hole

|

Through hole/Tapped hole

|

|

Raceway hardness

|

55-62HRC

|

|

Inner and outer ring

modulation hardness

|

229-269HB/Customized

|

|

Gear type

|

No gear ,Internal gear , External gear.

|

|

Embellish grease

|

EP2 lithium lubricating grease

|

|

Certificate

|

ABS.BV,DNV,ISO9001,GL

|

|

Application area

|

Ladle turret,Stacker crane,Bucket wheel machine,Solar heliostat Tracking System,port crane, Cabling machine,tower crane , offshore plaTECHNOLOGY LEADER IN THE DRIVES SECTOR Controlling movement with the highest precision – this challenge has been driving WITTENSTEIN for over 30 years now. This great determination has helped us become an undisputed global technology and quality leader.tform,ferris wheel, Palletizing robot,Rotary metallurgical furnace,can packing machine,Wind blade transporter,shield tunneling machine,tube push bench,excavator

|

|

Brand Name

|

HGB

|

|

Place of Origin

|

HangZhou Henan

|

|

Warranty

|

12 months

|

|

Payment term

|

T/T is our first choice

|

|

Packing details

|

1,Filling with anti-rust oil

2.Corved with Plastic paper

3.Corved with kraft paper

4.Corved with Blue tie

5.Put in wooden box

|

Product Details

|

Excavator Slewing Bearings are widely used for all brands of excavators, suit for follows models

|

|

Slewing Bearings For

Hita chi

|

EX40-1 EX60-1-2-3-5 EX70-5 EX90 EX100-1-2-3-5 EX110-5 EX120-1-2-3-5 EX130-5 EX200-1-2-3-5 EX210-5 EX220-5 EX270 EX300-1-2-3-5 EX-330 EX330-3 EX350-5 EX400-3 EX400-5 EX470-3 EX870 ZAX60 ZX55-R ZAX70 ZAX80 ZAX110 ZAX120 ZAX130 ZAX200-3-6 ZAX210 ZAX220-5 ZAX230 ZAX240 ZAX240-3 ZAX250-3 ZAX270-3 ZAX450-1 ZAX450-3 ZAX450-5 ZAX750 UH063 UH07-7 UH083

|

|

Slewing Bearings For E

|

E45 E60 E70B E80 E110 E120B E305 E311 E312B/C E307B/C/D E308 E315 E200 E200B E320 E320B E320C E320D E320L E324D E325/B/C/D E330/B/C E345/B E350 E365 E380 E385

|

|

Slewing Bearings For PC

|

PC30 PC30-2 PC35 PC40 PC45 PC50 PC50-7 PC55 PC60-5-6-7 PC70 PC75 PC78 PC100-3-5 PC120-3-5-6-6E PC128 PC130-7 PC150-5-7 PC160-7 PC200-1-2-3-4-5-6-7-8 PC210-7 PC220-3-5-6 PC240-8 PC227 PC228 PC270-7 PC300-1-2-3-4-5-6-7 PC350-6-7 PC360-6-7 PC400-3-5-6-7-8 PC450-5-6 PC460-7 PC600-6 PC650-3 PC650 PC800 PC1000 PC1200 PC1250

|

|

Slewing Bearings For Sumitomo

|

SH50 SH60-1 SH120-1-2/A1/A2/A3/Z3/C3 SH120C3 SH260 SH200 A1/A2/A3/C2/C3/Z3 SH210-5 SH210-A5 SH220-3 SH225 SH240-3-5 SH280 SH350

|

|

Slewing Bearings For Hyundai

|

R55-5-7 R60-5-7 R70-7 R80-7 R110-7 R130-5-7 R130LC-3-5 R150-7 R170-5 R200-3-5-7 R205-7 R210 R215-7 R220-5-7-9 R225LC-7 R260-7 R280 R290-7 R290LC-3 R290LC-7 R300LC R305LC-7 R320 R330LC R335-7 R375 R360LC-7 R450-7 R450LC R962

|

|

Slewing Bearings For Kato

|

DH35 DH55 DH60 DH80-7 DH150-5-7 DH200 DH215-7 DH220-2-3-5-7-9 DH258-7 DH280-5 DX60 DX200 DX225 DX260 DX300 DH280 DH290-5 DH300LC-7 DH340

DH360-5 DH370LC-7-9 DH420LC-7 DH500-7 DH550 DH600

|

|

Slewing Bearings For Kobelco

|

SK60-3-5 SK100 SK120-1-2-3-5 SK130-8 SK140-8 SK200-6 SK210-6 SK200-6E SK07 SK200-3-5-8 SK210-8 SK220 SK230-6 SK235 SK250-6-8 SK260-8 SK330-6 SK350-8 SK480-8

|

|

Slewing Bearings For LIUGONG & For XCMG

|

CLG906 CLG907 CLG908 CLG915 CLG915D CLG205C CLG225C CLG220LC CLG225 CLG200 CLG200-3 CLG920D CLG922D CLG925D CLG936LC CLG936D

XE60 XE210 XE215 XE150A/B XE230 XE370 210-8 220-8

|

|

Slewing Bearings For SANY

|

SY65 SY75 SY135 SY185 SY195 SY200 SY205 SY210 SY215-7-8-9 SY235 SY300 SY305 SY310 SY335 SY360 SY365 SY420

|

|

Slewing Bearings For Volov

|

EC55 EC210 EC210B EC240 EC290 EC360

|

|

Slewing Bearings For Liebherr

|

R914 R916 R924 R944

|

|

Slewing Bearings For Yuchai

|

YC15 YC20 YC35 YC60 YC6-5T YC85 YC210-8 YC230-8 YC350 YC400-8

|

|

Slewing Bearings For XGMA and For LONKIN

|

XG60 XG808 XG815 XG820 XG822 XG823 XSemi-permanently mounted power take-offs can also be found on industrial and marine engines. These applications typically use a drive shaft and bolted joint to transmit power to a secondary implement or accessory. In the case of a marine application, such shafts may be used to power fire pumps.G825

LG6060 LG6075 LG6085 LG6090 LG6210 LG6230 LG6225 LG6235

|

|

Slewing Bearings For Atlas and For Sunward

|

for Atlas3306LC 2006 TC360 2306

SWE50 SWE60 SWE70 SWE80 SWE90 SWE150

|

|

More Models for

|

For LovolFR85 FR150 FR210 For Bobcat80

For SW210 SW230 For Takeuchi135 175

For CASE CX210B For JCM906D JCM921 JCM922

For EPG75 161 For ZY80 ZY210

For JCB8056 JCB220 For ZW60 ZE80 JV60 SC360 HL60

|

Bearing Parts

Steel ball/Roller:carbon-chromium bearing steel GCr15SiMn or GCr15 for rolling Material

Cage: include integral cage, segment cage and spacer-type cage. 20# steel or copper for integral and segment cages, PA 1010 resin or QA110-3-105 albronze for spacer-type cages.

Seals:uses NBR or VITON, few felted wool.

Single row cross roller slewing bearing

Composed of two or three rings. compact structure, light weight, high manufacturing accuracy, small assembly gap and high requirement for installation accuracy. Rollers are 1:1 cross-arranged.

Can be bear axial force, overturning moment and large radial force at the same time,and widely used in lifting transportation, construction machinery and military products.

Three row roller slewing bearing

Three row roller bearing able to bear all kinds of loads at the same time, it is the largest one of the four structural products with large axle and radial dimensions and firm structure. Especially suitable for heavy machinery requiring larger diameter, such as bucket wheel stacker and reclaimer, wheel crane, marine crane, port crane, ladle turret,large tonnage truck crane,heavy machinery and so on.

Single row four point contact ball slewing bearing

Single row four point composed of two seat rings. has compact structure, light weight, and four-point contact between steel ball and arc raceway. It can bear axial force, radial force and overturning moment at the same time. The construction machinery of rotary conveyor, welding manipulator, small and medium-sized crane and excavator can be selected.

More Products

More Products

More Products

More Products

About Us

Wide production workshop and strong production team as a support,ensure the products can be produced by required quality and quantity. andThereby increase the customer benefits.

The above is our production equipment with advanced technology , the stable and longevity bearing produce from these equipment .

We specialize in the production of manufacturing slewing ring bearings or turntable Bearings.The Independent R&D and sales team in HGB , also do our best for special needs;We offer high-precision and high-quality slewing bearings, which are widly used in many fields,such as hoisting and conveying machinery, construction engineering machinery, harbour machinery, wind power generation, radar and missile launchers and so on.

Certificate

FAQ

1.Q: Are you trading company or manufacturer ?

A: We are professional slewing bearing manufacturer with 20 years’ experience.

2.Q: How long is your delivery time?

A: Generally it is 4-5 days if the goods are in stock. or it is 45 days if the goods are not in

stock, Also it is according to quantity.

3.Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample, it is extra.

4.Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance, balance before shipment.

5.Q: Can you provide special customization according to the working conditions?

A: Sure, we can design and produce the slewing bearings for different working conditions.

6.Q: How about your guarantee?

A: We provide lifelong after-sales technical service.

Contact Us

Wechat/Whatsapp: +86 13083988828

Skype: +86 13083988828

Company Name: HangZhou EPG – One of the bigggest transmission manufacturer in China – Ever-Power Transmission Bearing Technology Co., Ltd

Office Address: Room B8F, Block B, shenhua road 789 – jianqiaogongshe International, XiHu District, HangZhou City,China

Phone: +86 13083988828

Factory Address: Bearing zone in XiHu County, HangZhou City, China