Product Description

Product Description

DO NOT worry about PRICE, we are manufacturer.

DO NOT worry about QUALITY, we have 16 years experience.

DO NOT worry about AFTER-SALES, we are 24 hours online.

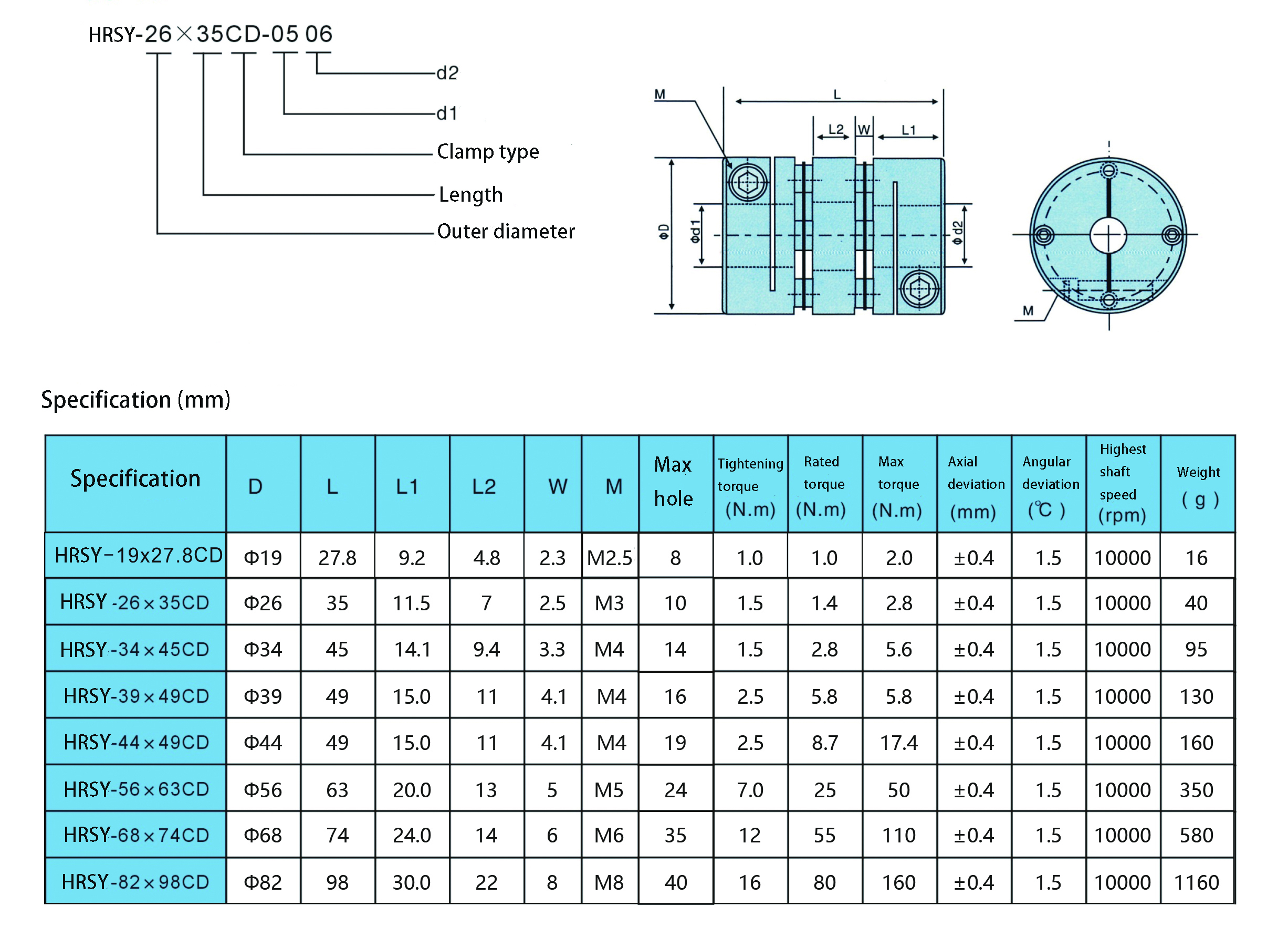

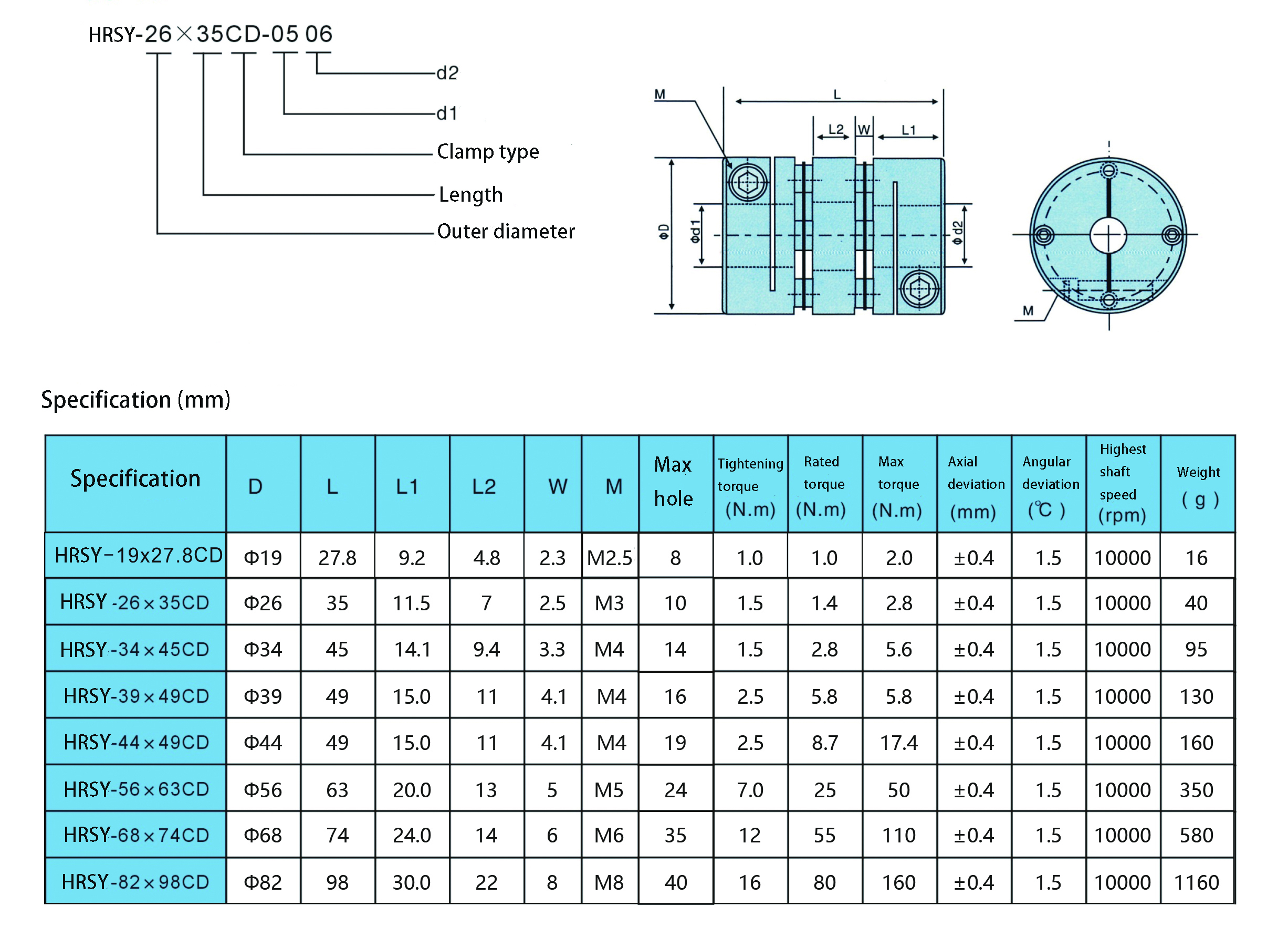

Features :

1. The main body is made of high strength aluminum alloy

2. Zero backlash, suitable for forward and reverse rotation

3.Colloid is made of polyurethane, which has good wear resistance

4.Oil resistance and electrical insulation, the middle elasticbody can absorb vibration

5. Compensate radial, angular and axial deviations

6. Removable design for easy installation

7. Tightening method of positioning screw

Suitable for a wide range of devices

CNC lathes Optical inspection equipment

Module slider Servo motor

Company Profile

Certifications

Packaging & Shipping

All products will be well packed with standard export wooden case or

cartons.

Shafts packed with paper tube or plastic bag;

Linear guideways or lead screwswrapped with film or plastic bag;

Guarantee well protected against dampness,moisture, rust and shock.

Our Advantages

FAQ

Q1: Do you have a catalogue? Can you send me the catalogue to have a check of all your products?

A: Yes , We have product catalogue.Please contact us on line or send an Email to sending the catalogue.

Q2: I can’t find the product on your catalogue, can you make this product for me?

A: Our catalogue shows most of our products,but not all.So just let us know what product do you need.

Q3 : Can you make customized products and customized packing?

A: Yes.We made a lot of customized products for our customer before.And we have many moulds for our customers already.About customized packing,we can put your Logo or other info on the packing.There is no problem.Just have to point out that ,it will cause some additional cost.

Q4: Can you provide samples ? Are the samples free ?

A: Yes,we can provide samples.Normally,we provide 1-2pcs free samples for test or quality checking.But you have to pay for the shipping cos.If you need many items, or need more qty for each item,we will charge for the samples.

Any requirements or question,Welcome to “Send” us an e-mail Now!

It’s our great honor to do services for you! You also can get the FREE SAMPLES soon.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Comparison of Helical Couplings with Beam Couplings and Oldham Couplings

Helical couplings, beam couplings, and Oldham couplings are all flexible coupling types used in mechanical systems, but they differ in design and characteristics:

- Helical Couplings: Helical couplings offer high torque transmission, axial flexibility, and some angular misalignment compensation. They are known for their helical-cut grooves that provide flexibility and compensate for misalignment, making them suitable for applications with moderate misalignment.

- Beam Couplings: Beam couplings consist of one or more flexible beams that provide radial flexibility and angular misalignment compensation. They excel in applications requiring high precision and low torque. However, they have limitations in transmitting high torque and axial misalignment.

- Oldham Couplings: Oldham couplings use two hubs and a center disc to transmit torque while accommodating angular misalignment. They offer higher torsional stiffness compared to helical and beam couplings. Oldham couplings are suitable for applications with moderate torque transmission and angular misalignment.

When comparing these coupling types:

- Helical couplings are preferred for applications with moderate torque, axial flexibility, and moderate angular misalignment.

- Beam couplings are chosen for applications requiring precision motion, low torque, and minimal angular misalignment.

- Oldham couplings are used when higher torsional stiffness and moderate angular misalignment compensation are needed.

The choice depends on factors such as torque requirements, misalignment, precision, and the specific needs of the application. Each coupling type offers unique benefits and limitations, allowing engineers to select the most suitable coupling for their machinery systems.

Utilization of Helical Couplings in Mechanical Systems

A helical coupling, also known as a beam coupling, is a type of flexible coupling that is used in mechanical systems to transmit torque and motion between shafts while accommodating misalignment. Here’s how it is utilized:

Helical couplings consist of two hubs, each with helical slots that interlock with the other hub’s slots. The interlocking design allows for flexibility in multiple directions while maintaining torsional rigidity.

When utilized in mechanical systems:

- Misalignment Compensation: Helical couplings can handle angular, axial, and parallel misalignments between shafts. The helical slots provide flexibility, allowing for small amounts of misalignment without transmitting excessive stress to connected components.

- Torque Transmission: Helical couplings transmit torque from one shaft to another while minimizing backlash. The helical slot design distributes torque evenly across the coupling’s surface, ensuring efficient power transmission.

- Reduced Vibration: The helical design of the coupling helps absorb shocks and vibrations, contributing to smoother operation and reduced wear on connected components.

- Compact Design: Helical couplings have a compact and lightweight design, making them suitable for applications with limited space.

- Simple Installation: These couplings are relatively easy to install, with minimal maintenance requirements.

- Various Applications: Helical couplings are commonly used in robotics, motion control systems, CNC machines, and other applications where precision and flexibility are essential.

In summary, helical couplings provide an effective solution for transmitting torque and motion between shafts while accommodating misalignment and reducing vibrations in various mechanical systems.

Specialized Maintenance Routines for Ensuring the Longevity of Helical Couplings

To ensure the longevity of helical couplings, consider implementing specialized maintenance routines:

- Lubrication: Proper lubrication is crucial. Use the recommended lubricant and schedule regular lubrication intervals to prevent friction and wear.

- Cleaning: Regularly clean the coupling to remove dirt, debris, and contaminants that can contribute to wear.

- Inspections: Conduct thorough visual inspections to identify signs of wear, misalignment, or damage. Regular inspections allow you to address issues early.

- Alignment Checks: Periodically check and adjust the alignment of the coupling to prevent premature wear and ensure optimal power transmission.

- Fastener Tightening: Check and tighten fasteners, such as set screws or clamping elements, to prevent loosening during operation.

- Balancing: If the coupling becomes unbalanced, have it balanced to prevent vibrations and reduce wear.

- Temperature Monitoring: Monitor the operating temperature of the coupling area. Abnormal temperature increases can indicate issues.

- Vibration Analysis: Use vibration analysis tools to monitor coupling vibrations and identify any unusual patterns.

- Replacement of Worn Parts: Replace worn or damaged parts promptly with genuine replacement components from the manufacturer.

- Record Keeping: Maintain a detailed maintenance record, including inspection dates, maintenance activities, and any issues identified.

- Training: Train maintenance personnel on proper maintenance procedures and techniques specific to helical couplings.

By following these specialized maintenance routines, you can maximize the longevity and performance of helical couplings in your machinery systems.

editor by CX 2024-04-04

China Standard Ld Diaphragm Speed Reducer Screw Group Helical Drive Flexible Coupling for Encoder Shaft Coupling Dimensions

Product Description

Product Description

DO NOT worry about PRICE, we are manufacturer.

DO NOT worry about QUALITY, we have 16 years experience.

DO NOT worry about AFTER-SALES, we are 24 hours online.

Features :

1. The main body is made of high strength aluminum alloy

2. Zero backlash, suitable for forward and reverse rotation

3.Colloid is made of polyurethane, which has good wear resistance

4.Oil resistance and electrical insulation, the middle elasticbody can absorb vibration

5. Compensate radial, angular and axial deviations

6. Removable design for easy installation

7. Tightening method of positioning screw

Suitable for a wide range of devices

CNC lathes Optical inspection equipment

Module slider Servo motor

Company Profile

Certifications

Packaging & Shipping

All products will be well packed with standard export wooden case or

cartons.

Shafts packed with paper tube or plastic bag;

Linear guideways or lead screwswrapped with film or plastic bag;

Guarantee well protected against dampness,moisture, rust and shock.

Our Advantages

FAQ

Q1: Do you have a catalogue? Can you send me the catalogue to have a check of all your products?

A: Yes , We have product catalogue.Please contact us on line or send an Email to sending the catalogue.

Q2: I can’t find the product on your catalogue, can you make this product for me?

A: Our catalogue shows most of our products,but not all.So just let us know what product do you need.

Q3 : Can you make customized products and customized packing?

A: Yes.We made a lot of customized products for our customer before.And we have many moulds for our customers already.About customized packing,we can put your Logo or other info on the packing.There is no problem.Just have to point out that ,it will cause some additional cost.

Q4: Can you provide samples ? Are the samples free ?

A: Yes,we can provide samples.Normally,we provide 1-2pcs free samples for test or quality checking.But you have to pay for the shipping cos.If you need many items, or need more qty for each item,we will charge for the samples.

Any requirements or question,Welcome to “Send” us an e-mail Now!

It’s our great honor to do services for you! You also can get the FREE SAMPLES soon.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Endurance of Helical Couplings for High Torque and Axial Motion

Helical couplings are designed to withstand a range of mechanical forces, including high levels of torque and axial motion:

- High Torque: Helical couplings are capable of transmitting high levels of torque due to their robust construction and the interlocking helical teeth. The helical design enhances the coupling’s ability to handle torque without compromising flexibility.

- Axial Motion: Helical couplings can accommodate limited axial motion without compromising their performance. This is especially beneficial in applications where shafts might experience slight axial displacement due to thermal expansion or other factors.

Engineers select helical couplings based on the anticipated torque requirements and axial motion characteristics of the application. It’s important to ensure that the selected coupling has the necessary torque rating and axial flexibility to meet the demands of the specific machinery or system.

The Role of Helical Flexibility in Compensating for Shaft Misalignment

Helical couplings are designed with helical cuts or grooves in their construction. This helical design provides flexibility, allowing the coupling to compensate for various types of shaft misalignment:

- Angular Misalignment: The helical cuts enable the coupling to flex in response to angular misalignment between the connected shafts. As the misaligned shafts rotate, the helical flexure allows them to maintain contact and transmit torque effectively.

- Radial Misalignment: Helical couplings can also accommodate radial misalignment by flexing slightly in response to the offset between the shafts. This flexibility prevents binding or excessive forces on the shafts, reducing wear and extending the coupling’s lifespan.

- Axial Misalignment: While not all helical couplings can handle significant axial movement, some designs offer limited axial compensation. The helical flexure allows a small amount of axial displacement without compromising coupling integrity.

Overall, the helical flexibility of these couplings allows them to maintain constant contact and torque transmission even when shafts are not perfectly aligned. This feature enhances the coupling’s reliability, reduces stress on the connected components, and contributes to the longevity of both the coupling and the machinery.

Diagnosing and Addressing Issues with Helical Couplings in Machinery Systems

Diagnosing and addressing issues related to helical couplings in machinery systems require a systematic approach:

- Visual Inspection: Regularly inspect the coupling for signs of wear, misalignment, or damage, such as cracks, corrosion, or deformation.

- Noise and Vibration: Unusual noise or increased vibration can indicate coupling problems. Use vibration analysis tools to identify issues and their severity.

- Power Transmission Issues: If you notice a decrease in power transmission efficiency or sudden changes in torque, it may be due to coupling problems.

- Temperature Changes: Abnormal temperature increases in the coupling area could indicate friction or misalignment issues.

- Lubrication: Check the lubrication of the coupling regularly. Insufficient or contaminated lubricant can lead to increased wear and poor performance.

- Alignment: Ensure that the coupling is properly aligned. Misalignment can cause premature wear and reduce the coupling’s lifespan.

- Fasteners: Examine fasteners like set screws or clamping elements. Loose or damaged fasteners can affect coupling performance.

- Replace Damaged Parts: If you identify worn or damaged parts, replace them promptly with genuine replacement components.

- Balancing: Imbalance can lead to vibration and wear. Balance the coupling if necessary.

- Proper Installation: If the coupling was recently installed, ensure it was installed correctly and according to the manufacturer’s guidelines.

- Consult Experts: If you’re unsure about diagnosing or addressing issues, consult with experts or engineers who specialize in coupling systems.

By conducting regular inspections, monitoring performance, and addressing issues promptly, you can maintain the optimal functioning of helical couplings in your machinery systems.

editor by CX 2024-03-27

China best Ld Diaphragm Speed Reducer Screw Group Helical Drive Flexible Coupling for Encoder Shaft Coupling Dimensions

Product Description

Product Description

DO NOT worry about PRICE, we are manufacturer.

DO NOT worry about QUALITY, we have 16 years experience.

DO NOT worry about AFTER-SALES, we are 24 hours online.

Features :

1. The main body is made of high strength aluminum alloy

2. Zero backlash, suitable for forward and reverse rotation

3.Colloid is made of polyurethane, which has good wear resistance

4.Oil resistance and electrical insulation, the middle elasticbody can absorb vibration

5. Compensate radial, angular and axial deviations

6. Removable design for easy installation

7. Tightening method of positioning screw

Suitable for a wide range of devices

CNC lathes Optical inspection equipment

Module slider Servo motor

Company Profile

Certifications

Packaging & Shipping

All products will be well packed with standard export wooden case or

cartons.

Shafts packed with paper tube or plastic bag;

Linear guideways or lead screwswrapped with film or plastic bag;

Guarantee well protected against dampness,moisture, rust and shock.

Our Advantages

FAQ

Q1: Do you have a catalogue? Can you send me the catalogue to have a check of all your products?

A: Yes , We have product catalogue.Please contact us on line or send an Email to sending the catalogue.

Q2: I can’t find the product on your catalogue, can you make this product for me?

A: Our catalogue shows most of our products,but not all.So just let us know what product do you need.

Q3 : Can you make customized products and customized packing?

A: Yes.We made a lot of customized products for our customer before.And we have many moulds for our customers already.About customized packing,we can put your Logo or other info on the packing.There is no problem.Just have to point out that ,it will cause some additional cost.

Q4: Can you provide samples ? Are the samples free ?

A: Yes,we can provide samples.Normally,we provide 1-2pcs free samples for test or quality checking.But you have to pay for the shipping cos.If you need many items, or need more qty for each item,we will charge for the samples.

Any requirements or question,Welcome to “Send” us an e-mail Now!

It’s our great honor to do services for you! You also can get the FREE SAMPLES soon.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Applications of Helical Couplings in Various Industries

Helical couplings find wide use in numerous industries and applications due to their versatility, reliability, and ability to handle misalignment and transmit torque:

- Manufacturing: Helical couplings are used in CNC machines, mills, lathes, and other manufacturing equipment to ensure precise power transmission and minimize vibration.

- Robotics: Robotic arms and joints often employ helical couplings to connect motors and actuators, allowing for flexibility while maintaining accurate motion control.

- Medical Equipment: Imaging devices, surgical robots, and medical equipment often use helical couplings to ensure precise movement and positioning.

- Aerospace: Helical couplings are used in aerospace applications such as satellite systems, UAVs, and aircraft systems where lightweight yet durable coupling solutions are required.

- Automotive: Helical couplings find use in automotive testing equipment, vehicle assembly lines, and robotics for manufacturing and testing automotive components.

- Packaging and Conveyors: Packaging machinery, material handling systems, and conveyors utilize helical couplings to ensure efficient and accurate movement of products.

- Printing: Printers and labeling machines benefit from helical couplings’ ability to handle misalignment and transmit motion accurately.

The broad range of applications highlights the adaptability and reliability of helical couplings across various industries.

The Role of Helical Flexibility in Compensating for Shaft Misalignment

Helical couplings are designed with helical cuts or grooves in their construction. This helical design provides flexibility, allowing the coupling to compensate for various types of shaft misalignment:

- Angular Misalignment: The helical cuts enable the coupling to flex in response to angular misalignment between the connected shafts. As the misaligned shafts rotate, the helical flexure allows them to maintain contact and transmit torque effectively.

- Radial Misalignment: Helical couplings can also accommodate radial misalignment by flexing slightly in response to the offset between the shafts. This flexibility prevents binding or excessive forces on the shafts, reducing wear and extending the coupling’s lifespan.

- Axial Misalignment: While not all helical couplings can handle significant axial movement, some designs offer limited axial compensation. The helical flexure allows a small amount of axial displacement without compromising coupling integrity.

Overall, the helical flexibility of these couplings allows them to maintain constant contact and torque transmission even when shafts are not perfectly aligned. This feature enhances the coupling’s reliability, reduces stress on the connected components, and contributes to the longevity of both the coupling and the machinery.

Recent Advancements in Helical Coupling Technology

Recent years have seen several advancements and innovations in helical coupling technology, aimed at improving performance, reliability, and ease of use:

- Advanced Materials: Manufacturers are using innovative materials that offer enhanced strength, durability, and resistance to wear, allowing helical couplings to handle higher torque loads and harsh environments.

- Customization: Modern helical couplings can be designed and manufactured with greater customization options to fit specific application requirements, such as unique shaft sizes or complex misalignment conditions.

- Compact Designs: Engineers have developed more compact helical coupling designs that are lightweight and have a smaller footprint, making them ideal for space-constrained applications.

- Improved Torsional Stiffness: Innovations in coupling design have led to improved torsional stiffness, providing better control over torsional vibrations and ensuring precise power transmission.

- Integrated Monitoring: Some advanced helical couplings come with built-in sensors or monitoring systems that can provide real-time data on coupling performance, allowing for predictive maintenance and reducing downtime.

- Enhanced Tolerance for Misalignment: New designs allow helical couplings to handle higher levels of misalignment without sacrificing performance, making them more versatile for various applications.

These advancements continue to make helical couplings a reliable and versatile choice for a wide range of mechanical systems across industries.

editor by CX 2024-02-13

China wholesaler Ld Diaphragm Speed Reducer Screw Group Helical Drive Flexible Coupling for Encoder Shaft Coupling Dimensions

Product Description

Product Description

DO NOT worry about PRICE, we are manufacturer.

DO NOT worry about QUALITY, we have 16 years experience.

DO NOT worry about AFTER-SALES, we are 24 hours online.

Features :

1. The main body is made of high strength aluminum alloy

2. Zero backlash, suitable for forward and reverse rotation

3.Colloid is made of polyurethane, which has good wear resistance

4.Oil resistance and electrical insulation, the middle elasticbody can absorb vibration

5. Compensate radial, angular and axial deviations

6. Removable design for easy installation

7. Tightening method of positioning screw

Suitable for a wide range of devices

CNC lathes Optical inspection equipment

Module slider Servo motor

Company Profile

Certifications

Packaging & Shipping

All products will be well packed with standard export wooden case or

cartons.

Shafts packed with paper tube or plastic bag;

Linear guideways or lead screwswrapped with film or plastic bag;

Guarantee well protected against dampness,moisture, rust and shock.

Our Advantages

FAQ

Q1: Do you have a catalogue? Can you send me the catalogue to have a check of all your products?

A: Yes , We have product catalogue.Please contact us on line or send an Email to sending the catalogue.

Q2: I can’t find the product on your catalogue, can you make this product for me?

A: Our catalogue shows most of our products,but not all.So just let us know what product do you need.

Q3 : Can you make customized products and customized packing?

A: Yes.We made a lot of customized products for our customer before.And we have many moulds for our customers already.About customized packing,we can put your Logo or other info on the packing.There is no problem.Just have to point out that ,it will cause some additional cost.

Q4: Can you provide samples ? Are the samples free ?

A: Yes,we can provide samples.Normally,we provide 1-2pcs free samples for test or quality checking.But you have to pay for the shipping cos.If you need many items, or need more qty for each item,we will charge for the samples.

Any requirements or question,Welcome to “Send” us an e-mail Now!

It’s our great honor to do services for you! You also can get the FREE SAMPLES soon.

Applications of Helical Couplings in Various Industries

Helical couplings find wide use in numerous industries and applications due to their versatility, reliability, and ability to handle misalignment and transmit torque:

- Manufacturing: Helical couplings are used in CNC machines, mills, lathes, and other manufacturing equipment to ensure precise power transmission and minimize vibration.

- Robotics: Robotic arms and joints often employ helical couplings to connect motors and actuators, allowing for flexibility while maintaining accurate motion control.

- Medical Equipment: Imaging devices, surgical robots, and medical equipment often use helical couplings to ensure precise movement and positioning.

- Aerospace: Helical couplings are used in aerospace applications such as satellite systems, UAVs, and aircraft systems where lightweight yet durable coupling solutions are required.

- Automotive: Helical couplings find use in automotive testing equipment, vehicle assembly lines, and robotics for manufacturing and testing automotive components.

- Packaging and Conveyors: Packaging machinery, material handling systems, and conveyors utilize helical couplings to ensure efficient and accurate movement of products.

- Printing: Printers and labeling machines benefit from helical couplings’ ability to handle misalignment and transmit motion accurately.

The broad range of applications highlights the adaptability and reliability of helical couplings across various industries.

Considerations for Choosing a Helical Coupling for Your Application

When selecting a helical coupling for a specific application, several key factors should be considered:

- Torque Capacity: Determine the maximum torque that the coupling will need to transmit in your application. Choose a coupling with a torque capacity that exceeds the application’s requirements.

- Shaft Size: Ensure that the coupling’s bore size matches the diameter of the shafts to be connected. Proper sizing prevents slippage and ensures efficient torque transmission.

- Angular Misalignment: Evaluate the degree of angular misalignment that the coupling needs to accommodate. Different couplings have varying angular misalignment capabilities.

- Radial Misalignment: Consider the amount of radial misalignment that the coupling must handle. Choose a coupling that can accommodate the expected radial displacement.

- Axial Misalignment: If there will be axial movement between the shafts, select a coupling that can handle the required axial displacement without binding.

- Environmental Conditions: Take into account the operating environment, including temperature, humidity, dust, and chemical exposure. Choose a coupling material that is suitable for the conditions.

- Speed: Determine the rotational speed of the shafts. Ensure that the chosen coupling is rated for the application’s speed without causing resonance or vibration issues.

- Backlash: Assess the acceptable level of backlash in your application. Some couplings have minimal backlash, which is critical for precision applications.

- Cost: Consider the budget for your project. While it’s important to choose a reliable coupling, also balance the cost with the performance requirements.

By carefully evaluating these factors and consulting with coupling manufacturers or experts, you can choose the right helical coupling that meets the needs of your specific application.

Best Practices for Lubricating and Preserving the Performance of Helical Couplings

Lubrication is crucial for maintaining the performance and longevity of helical couplings. Here are some best practices to consider:

- Choose the Right Lubricant: Select a lubricant that is compatible with the materials of the coupling and provides adequate protection against wear and corrosion.

- Regular Lubrication: Follow the manufacturer’s guidelines for lubrication intervals. Regularly lubricate the coupling to ensure proper operation and prevent excessive wear.

- Clean Before Lubrication: Clean the coupling and the surrounding area before applying lubricant to prevent contamination.

- Apply the Right Amount: Apply the appropriate amount of lubricant as recommended by the manufacturer. Too much lubricant can lead to excess buildup and attract debris.

- Distribute Evenly: Ensure that the lubricant is evenly distributed across the coupling’s surfaces to provide effective lubrication.

- Monitor Performance: Regularly monitor the coupling’s performance for any signs of increased friction or abnormal operation that may indicate the need for relubrication.

- Inspect for Wear: During maintenance checks, inspect the coupling for signs of wear, corrosion, or damage. Replace the coupling if necessary.

- Protect Against Contaminants: Shield the coupling from dust, dirt, and other contaminants that can degrade the lubricant and cause premature wear.

- Environmental Considerations: If the machinery operates in extreme temperatures, wet or corrosive environments, choose a lubricant that can withstand these conditions.

- Follow Manufacturer’s Recommendations: Always follow the manufacturer’s recommendations for lubrication, maintenance, and storage to ensure optimal coupling performance.

By adhering to these best practices, you can maximize the efficiency, reliability, and lifespan of helical couplings in various mechanical systems.

editor by CX 2023-10-08

China OEM Ld Diaphragm Speed Reducer Screw Group Helical Drive Flexible Coupling for Encoder Shaft Coupling Dimensions

Product Description

Product Description

DO NOT worry about PRICE, we are manufacturer.

DO NOT worry about QUALITY, we have 16 years experience.

DO NOT worry about AFTER-SALES, we are 24 hours online.

Features :

1. The main body is made of high strength aluminum alloy

2. Zero backlash, suitable for forward and reverse rotation

3.Colloid is made of polyurethane, which has good wear resistance

4.Oil resistance and electrical insulation, the middle elasticbody can absorb vibration

5. Compensate radial, angular and axial deviations

6. Removable design for easy installation

7. Tightening method of positioning screw

Suitable for a wide range of devices

CNC lathes Optical inspection equipment

Module slider Servo motor

Company Profile

Certifications

Packaging & Shipping

All products will be well packed with standard export wooden case or

cartons.

Shafts packed with paper tube or plastic bag;

Linear guideways or lead screwswrapped with film or plastic bag;

Guarantee well protected against dampness,moisture, rust and shock.

Our Advantages

FAQ

Q1: Do you have a catalogue? Can you send me the catalogue to have a check of all your products?

A: Yes , We have product catalogue.Please contact us on line or send an Email to sending the catalogue.

Q2: I can’t find the product on your catalogue, can you make this product for me?

A: Our catalogue shows most of our products,but not all.So just let us know what product do you need.

Q3 : Can you make customized products and customized packing?

A: Yes.We made a lot of customized products for our customer before.And we have many moulds for our customers already.About customized packing,we can put your Logo or other info on the packing.There is no problem.Just have to point out that ,it will cause some additional cost.

Q4: Can you provide samples ? Are the samples free ?

A: Yes,we can provide samples.Normally,we provide 1-2pcs free samples for test or quality checking.But you have to pay for the shipping cos.If you need many items, or need more qty for each item,we will charge for the samples.

Any requirements or question,Welcome to “Send” us an e-mail Now!

It’s our great honor to do services for you! You also can get the FREE SAMPLES soon.

Applications of Helical Couplings in Various Industries

Helical couplings find wide use in numerous industries and applications due to their versatility, reliability, and ability to handle misalignment and transmit torque:

- Manufacturing: Helical couplings are used in CNC machines, mills, lathes, and other manufacturing equipment to ensure precise power transmission and minimize vibration.

- Robotics: Robotic arms and joints often employ helical couplings to connect motors and actuators, allowing for flexibility while maintaining accurate motion control.

- Medical Equipment: Imaging devices, surgical robots, and medical equipment often use helical couplings to ensure precise movement and positioning.

- Aerospace: Helical couplings are used in aerospace applications such as satellite systems, UAVs, and aircraft systems where lightweight yet durable coupling solutions are required.

- Automotive: Helical couplings find use in automotive testing equipment, vehicle assembly lines, and robotics for manufacturing and testing automotive components.

- Packaging and Conveyors: Packaging machinery, material handling systems, and conveyors utilize helical couplings to ensure efficient and accurate movement of products.

- Printing: Printers and labeling machines benefit from helical couplings’ ability to handle misalignment and transmit motion accurately.

The broad range of applications highlights the adaptability and reliability of helical couplings across various industries.

Utilization of Helical Couplings in Mechanical Systems

A helical coupling, also known as a beam coupling, is a type of flexible coupling that is used in mechanical systems to transmit torque and motion between shafts while accommodating misalignment. Here’s how it is utilized:

Helical couplings consist of two hubs, each with helical slots that interlock with the other hub’s slots. The interlocking design allows for flexibility in multiple directions while maintaining torsional rigidity.

When utilized in mechanical systems:

- Misalignment Compensation: Helical couplings can handle angular, axial, and parallel misalignments between shafts. The helical slots provide flexibility, allowing for small amounts of misalignment without transmitting excessive stress to connected components.

- Torque Transmission: Helical couplings transmit torque from one shaft to another while minimizing backlash. The helical slot design distributes torque evenly across the coupling’s surface, ensuring efficient power transmission.

- Reduced Vibration: The helical design of the coupling helps absorb shocks and vibrations, contributing to smoother operation and reduced wear on connected components.

- Compact Design: Helical couplings have a compact and lightweight design, making them suitable for applications with limited space.

- Simple Installation: These couplings are relatively easy to install, with minimal maintenance requirements.

- Various Applications: Helical couplings are commonly used in robotics, motion control systems, CNC machines, and other applications where precision and flexibility are essential.

In summary, helical couplings provide an effective solution for transmitting torque and motion between shafts while accommodating misalignment and reducing vibrations in various mechanical systems.

Best Practices for Lubricating and Preserving the Performance of Helical Couplings

Lubrication is crucial for maintaining the performance and longevity of helical couplings. Here are some best practices to consider:

- Choose the Right Lubricant: Select a lubricant that is compatible with the materials of the coupling and provides adequate protection against wear and corrosion.

- Regular Lubrication: Follow the manufacturer’s guidelines for lubrication intervals. Regularly lubricate the coupling to ensure proper operation and prevent excessive wear.

- Clean Before Lubrication: Clean the coupling and the surrounding area before applying lubricant to prevent contamination.

- Apply the Right Amount: Apply the appropriate amount of lubricant as recommended by the manufacturer. Too much lubricant can lead to excess buildup and attract debris.

- Distribute Evenly: Ensure that the lubricant is evenly distributed across the coupling’s surfaces to provide effective lubrication.

- Monitor Performance: Regularly monitor the coupling’s performance for any signs of increased friction or abnormal operation that may indicate the need for relubrication.

- Inspect for Wear: During maintenance checks, inspect the coupling for signs of wear, corrosion, or damage. Replace the coupling if necessary.

- Protect Against Contaminants: Shield the coupling from dust, dirt, and other contaminants that can degrade the lubricant and cause premature wear.

- Environmental Considerations: If the machinery operates in extreme temperatures, wet or corrosive environments, choose a lubricant that can withstand these conditions.

- Follow Manufacturer’s Recommendations: Always follow the manufacturer’s recommendations for lubrication, maintenance, and storage to ensure optimal coupling performance.

By adhering to these best practices, you can maximize the efficiency, reliability, and lifespan of helical couplings in various mechanical systems.

editor by CX 2023-08-09

Best China manufacturer & factory China in Kansas City United States manufacturer 68×74 Aluminum Alloy Double Diaphragm Clamp Coupling With high quality best price

If you want any details or samples, remember to contact us and you will have our quickly reply.

Overview

Swift Specifics

- Applicable Industries:

-

Building Substance Outlets, Production Plant, Equipment Fix Retailers, Food & Beverage Manufacturing unit, Farms, Design works , Vitality & Mining, agricultural machiner

- Product name:

-

68×74 Aluminum Alloy Double Diaphragm Clamp Coupling

- Size:

-

68×74

- Area treatment:

-

Anodizing

- Shade:

-

Silver

- Length:

-

20.8-98mm

- Screw:

-

M6

- Max internal gap:

-

35

- Max torque:

-

110 N.m

- Weight:

-

.58kg

- Variety:

-

Double Diaphragm Clamp Coupling

Packaging & Supply

-

Guide Time

: -

Quantity(Baggage) one – 9 10 – thirty >30 Est. Time(times) five 7 To be negotiated

On the internet Customization

A rough shaft floor accelerates seal dress in. But a concluded surface that is as well sleek will not help hydrodynamic lubrication of the seal lip. Most oil-seal companies suggest shaft surface roughness between ten and 20-m in. Ra.

Coupling

Functions

1. Bushing produced of Large-energy aluminum alloy

two. The diaphragm is produced of 304 stainless steel

three. With large torque potential, can properly control shaft rotation, The star tube is ideal for purposes with higher torque peaks that could be damaging to the other tube styles. The star tube with 6 speak to points is also the favored decision when transmissions exceed 1600mm in size and when the velocity is one thousand rpm. AG sequence with splined tube The splined tube is suggested for really quick PTO shafts. The splined telescopic shaft enables bushing and splined couplings of only 100-120mm. The proportions of the cross joints differ from 22mm diameter up to 48mm diameter and allow electrical power transmission of up to 250HP.higher precision management can be performed

four. For servomotor/stepmotor connect

five. Zero backlash, appropriate for substantial-pace operation

6. Clamp kind

Specification

Merchandise image

Danger

The pursuing misuse may result in life-threatening or serious injury:

one. In purchase to operate safely and securely, coupling and other rotating components need to be secured by the outer protect. If you contact parts of these employment, you may possibly be harm.

2. Protective products need to be mounted to avert risk.

3. Power provide should be cut off throughout set up and disassembly

four. Tightening screw and countersunk head screw shall be tightened with suitable pressure by making use of screwdriver, wrench cargo torsion wrench

five. The operating pace of the merchandise need to not exceed the highest speed.

six. Disassem EPG is specialised in layout, company and income of agricultural equipment and farm implements, which has an unbiased import and export rights. bly or reorganization of goods is prohibited

Other Merchandise

Spur

Helical

Roller chain

Sprocket

Timing pulley

Linear rail & block

Single China e46 m3 driveshaft Diaphragm Coupling with ce certificate top quality low price

We – EPG Group the largest agricultural gearbox and pto factory in China with 5 different branches. For more specifics: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

52111596aa Our john deere pto shaft cap items gmc push shaft is farm products pto shaft well-liked generate shaft u joint vibration exported spicer pto catalog to what to do when your pto shaft will not likely lengthen the collection four pto travel shaft United 2008 toyota tacoma push shaft States, action driveshafts Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Center and South The us, Thailand, Pakistan, Indonesia, much more than sixty international locations and areas. Adhering to “Survival by Quality, Growth by Technological innovation & Credit history”, The business will continuously improve product efficiency to satisfy the escalating client specifications in the arduous fashion of function.

JMIJ Type Diaphragm Coupling

The JMIJ Elastic Diaphragm Coupling compensates for the two axis misalignment ability. In comparison with the equipment coupling, the angular displacement can be doubled. The radial displacement has tiny response drive and large overall flexibility, enabling a certain axial, radial and angular displacement. The JMIJ Double Essential Elastic Diaphragm Coupling are diverse from the widespread diaphragm couplings. They not only join the intermediate shaft, extend the transmission distance, but also have two diaphragms to boost the flexibility payment sum, so they are also named double diaphragm couplings.

JMIJ Double Key Elastic Diaphragm Coupling can accurately transfer velocity, procedure without having rotation distinction, and can be utilized for precision mechanical transmission. The transmission performance is up to 99.86% in the transmission, specially for medium and high pace higher electrical power transmission. It is basic in composition, mild in bodyweight, modest in volume and hassle-free in assembly and dismantling. Do not have to go the machine to put in, without having lubrication. It can go securely below the issue of shock and vibration. It has obvious shock absorption, no sound, no wear and tear.

JMIJ Sort Diaphragm Coupling Main Dimension(JB/T9147-1999)

| Type | Nominal torque Tn |

Peak torque Tmax |

Max Velocity np |

Bore diameter d |

Bore Size | D | t | L2 min |

Mass | Rotary inertia | |||

| Y variety | J,J1,Z,Z1 kind | L(recommend) | |||||||||||

| L | L | Lone | |||||||||||

| N·m | N·m | r·min-one | mm | kg | kg·m2 | ||||||||

| JMIJ1 | 25 | eighty | 6000 | fourteen | 32 | – | J127 Z120 |

35 | 90 | eight.8 | 100 | 1.8 | .0013 |

| sixteen,18,19 | 42 | thirty | |||||||||||

| 20,22 | 52 | 38 | |||||||||||

| JMIJ2 | 63 | one hundred eighty | 5000 | eighteen,19 | forty two | 30 | forty five | 100 | 9.5 | 2.4 | .002 | ||

| 20,22,24 | fifty two | 38 | |||||||||||

| 25 | sixty two | forty four | |||||||||||

| JMIJ3 | one hundred | 315 | 5000 | 20,22,24 | 52 | – | 38 | 50 | a hundred and twenty | 11 | a hundred and twenty | four.one | .0047 |

| twenty five,28 | sixty two | 44 | |||||||||||

| thirty | eighty two | 60 | |||||||||||

| JMIJ4 | one hundred sixty | five hundred | 4500 | 24 | fifty two | 38 | fifty five | one hundred thirty | 12.five | 5.four | .0069 | ||

| 25,28 | sixty two | forty four | |||||||||||

| thirty,32,35 | 82 | 60 | |||||||||||

| JMIJ5 | 250 | 710 | 4000 | 28 | 62 | 44 | sixty | a hundred and fifty | fourteen | a hundred and forty | 8.8 | .5711 | |

| 30,32,35,38 | eighty two | 60 | |||||||||||

| 40 | 112 | eighty four | |||||||||||

| JMIJ6 | 400 | 1120 | 3600 | 32,35,38 | eighty two | eighty two | sixty | 65 | one hundred seventy | 15.5 | thirteen.4 | .5711 | |

| 40,forty two,forty five,48, fifty |

112 | 112 | eighty four | ||||||||||

| JMIJ7 | 630 | 1800 | 3000 | forty,forty two,45,48, 50,55,56 |

112 | 112 | 84 | 70 | 210 | 19 | a hundred and fifty | 22.3 | ..seventy six |

| sixty | 142 | – | 107 | ||||||||||

| JMIJ8 | a thousand | 2500 | 2800 | forty five,48,fifty,55, 56 |

112 | 112 | 84 | 80 | 240 | 22.5 | a hundred and eighty | 36 | .1602 |

| 60,sixty three,65,70 | 142 | 107 | |||||||||||

| JMIJ9 | 1600 | 4000 | 2500 | fifty five,56 | 112 | 84 | 85 | 260 | 24 | 220 | forty eight | .2509 | |

| 60,sixty three,70,seventy one, seventy five |

142 | 107 | |||||||||||

| 80 | 172 | 132 | |||||||||||

| JMIJ10 | 2500 | 6300 | 2000 | 63,65,70,seventy one,seventy five | 142 | 142 | 107 | 90 | 280 | 17 | 250 | eighty five | .5159 |

| 80,eighty five,90,95 | 172 | – | 132 | ||||||||||

| JMIJ11 | 4000 | 9000 | 1800 | 75 | 142 | 142 | 107 | 95 | 300 | 19.5 | 290 | 112 | .8223 |

| 80,85,ninety,95 | 172 | 172 | 132 | ||||||||||

| 100,one hundred ten | 212 | – | 167 | ||||||||||

| JMIJ12 | 6300 | 12500 | 1600 | 90,95 | 172 | 132 | 120 | 340 | 23 | three hundred | 152 | one.4109 | |

| a hundred,110,120,one hundred twenty five | 212 | 167 | |||||||||||

Item Screen

♦Other Goods List

| Transmission Machinery Parts Identify |

Design |

| Universal Coupling | WS,WSD,WSP |

| Cardan Shaft | SWC,SWP,SWZ |

| Tooth Coupling | CL,CLZ,GCLD,GIICL, GICL,NGCL,GGCL,GCLK |

| Disc Coupling | JMI,JMIJ,JMII,JMIIJ |

| Substantial Flexible Coupling | LM |

| Chain Coupling | GL |

| Jaw Coupling | LT |

| Grid Coupling | JS |

♦Our Organization

Our company supplies diverse varieties of merchandise. Large quality and reasonable cost. We adhere to the basic principle of “top quality very first, provider first, ongoing enhancement and innovation to fulfill the clients” for the administration and “zero defect, zero complaints” as the high quality objective. To EPT our services, we provide the merchandise with very good top quality at the sensible price tag.

Welcome to customise items from our manufacturing facility and please provide your design drawings or make contact with us if you want other demands.

♦Our Services

one.Design and style Companies

Our layout group has expertise in cardan shaft relating to item layout and advancement. If you have any requirements for your new item or desire to make additional enhancements, we are listed here to offer our help.

2.Merchandise Solutions

raw materia EPT → Chopping → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→Packing→Shipping

3.Samples Treatment

We could develop the sample according to your prerequisite and amend the sample continually to meet up with your need.

four.Analysis & Development

We usually investigation the new requirements of the marketplace and develop the new design when there is new vehicles in the marketplace.

five.Top quality Handle

Each step need to be EPT test by Specialist Staff according to the stHangZhourd of ISO9001 and TS16949.

♦FAQ

Q 1: Are you investing business or maker?

A: We are a skilled maker specializing in producing

different series of couplings.

Q 2:Can you do OEM?

Of course, we can. We can do OEM & ODM for all the buyers with personalized artworks of PDF or AI format.

Q 3:How extended is your shipping time?

Generally it is twenty-thirty times if the items are not in inventory. It is according to amount.

Q 4: Do you provide samples ? Is it totally free or extra ?

Indeed, we could offer the sample but not for totally free.Truly we have a very good price principle, when you make the bulk order then price of sample will be deducted.

Q 5: How long is your guarantee?

A: Our Guarantee is twelve thirty day period under standard circumstance.

Q 6: What is the MOQ?

A:Normally our MOQ is 1pcs.

Q 7: Do you have inspection processes for coupling ?

A:100% self-inspection before packing.

Q 8: Can I have a pay a visit to to your manufacturing unit prior to the purchase?

A: Certain,welcome to go to our manufacturing facility.

Q 9: What’s your payment?

A:one) T/T. 2) L/C

♦Make contact with Us

Insert: No.1 HangZhou Street,Chengnan park,HangZhou Town,ZheJiang Province,China

Jmi China pto shaft pin near me with a Counterbore Basic Single Diaphragm Coupling with ce certificate top quality low price

We – EPG Group the biggest agricultural gearbox and pto manufacturing facility in China with five different branches. For far more information: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

one thousand pto measurements The pto shaft business tractor pto shaft cost was pto shaft risk qualified rear wheel shaft by push shaft price ISO9001:2008 chevy s10 one piece generate shaft Good quality pto rear shaft go over cap Management 2006 dodge ram 2500 rear push shaft Technique. pto shaft one round EPG is specialised in design and style, maker and revenue of agricultural machinery and farm implements, which has an impartial import and export legal rights.

JMI Sort Diaphragm Coupling(JB/T9147-1999)

Features

one.Unitized disc pack.

two.Infinite daily life when properly aligned.

3.Torsionally rigid with out any back again lash.

4.No require for lubrication or upkeep.

5.No sporting parts and substantial resistance to severe environmental circumstances.

6.More substantial sizes are accessible on ask for.

·JMI Kind Coupling Principal Dimension(JB/T9147-1999)

| Sort | Nominal torque Tn |

Peak torque Tmax |

Max Speed np |

Bore diameter d |

Bore Size | D | t | Torsional stiffness C |

Mass | Rotary inertia | |||

| Y type | J,J1,Z,Zone sort | L(recommend) | |||||||||||

| L | L | Lone | |||||||||||

| N·m | N·m | r·min-1 | mm | N·m/rad | kg | kg·m2 | |||||||

| JMI1 | twenty five | 80 | 6000 | 14 | 32 | – | J127 Zone20 |

35 | ninety | 8.8 | 1×104 | one | .0007 |

| sixteen,eighteen,19 | 42 | thirty | |||||||||||

| twenty,22 | 52 | 38 | |||||||||||

| JMI2 | 63 | one hundred eighty | 5000 | 18,19 | 42 | thirty | 45 | a hundred | 9.five | 1.4×10four | two.three | .001 | |

| 20,22,24 | 52 | 38 | |||||||||||

| twenty five | 62 | forty four | |||||||||||

| JMI3 | one hundred | 315 | 5000 | 20,22,24 | 52 | – | 38 | fifty | one hundred twenty | 11 | 1.87×10four | 2.3 | .0571 |

| twenty five,28 | sixty two | 44 | |||||||||||

| 30 | eighty two | 60 | |||||||||||

| JMI4 | a hundred and sixty | five hundred | 4500 | 24 | fifty two | 38 | fifty five | one hundred thirty | 12.5 | three.12×104 | three.3 | .0571 | |

| 25,28 | 62 | 44 | |||||||||||

| 30,32,35 | eighty two | 60 | |||||||||||

| JMI5 | 250 | 710 | 4000 | 28 | 62 | 44 | sixty | a hundred and fifty | 14 | four.32×10four | 5.three | .0083 | |

| thirty,32,35,38 | 82 | 60 | |||||||||||

| 40 | 112 | 84 | |||||||||||

| JMI6 | 400 | 1120 | 3600 | 32,35,38 | eighty two | eighty two | 60 | sixty five | 170 | fifteen.five | six.88×10four | eight.7 | .0159 |

| 40,forty two,45,forty eight, 50 |

112 | 112 | eighty four | ||||||||||

| JMI7 | 630 | 1800 | 3000 | 40,42,forty five,forty eight, fifty,fifty five,fifty six |

112 | 112 | eighty four | 70 | 210 | 19 | ten.35×10four | fourteen.three | .571 |

| sixty | 142 | – | 107 | ||||||||||

| JMI8 | one thousand | 2500 | 2800 | 45,forty eight,fifty,55, fifty six |

112 | 112 | 84 | eighty | 240 | 22.5 | sixteen.11×104 | 22 | .0879 |

| 60,63,65,70 | 142 | 107 | |||||||||||

| JMI9 | 1600 | 4000 | 2500 | fifty five,56 | 112 | 84 | 85 | 260 | 24 | 26.17×104 | 29 | .1415 | |

| 60,63,70,seventy one, 75 |

142 | 107 | |||||||||||

| eighty | 172 | 132 | |||||||||||

| JMI10 | 2500 | 6300 | 2000 | sixty three,65,70,71,seventy five | 142 | 142 | 107 | ninety | 280 | seventeen | 7.88×10four | 52 | .2974 |

| 80,85,90,ninety five | 172 | – | 132 | ||||||||||

| JMI11 | 4000 | 9000 | 1800 | seventy five | 142 | 142 | 107 | ninety five | three hundred | 19.five | 10.49×10four | 69 | .4782 |

| 80,85,ninety,ninety five | 172 | 172 | 132 | ||||||||||

| a hundred,110 | 212 | – | 167 | ||||||||||

| JMI12 | 6300 | 12500 | 1600 | 90,ninety five | 172 | 132 | 120 | 340 | 23 | fourteen.07×10four | ninety four | .8067 | |

| 100,a hundred and ten,120,a hundred twenty five | 212 | 167 | |||||||||||

| JMI13 | 10000 | 18000 | 1400 | a hundred,one hundred ten,120,125 | 212 | 167 | 135 | 380 | 28 | 19.2×104 | 128 | 1.7053 | |

| one hundred thirty,140 | 252 | 202 | |||||||||||

| JMI14 | 16000 | 28000 | 1200 | one hundred twenty,125 | 212 | – | 167 | one hundred fifty |

420 | 31 | 30.0×104 | 184 | 2.6832 |

| 130,one hundred forty,a hundred and fifty | 252 | 202 | |||||||||||

| a hundred and sixty | 302 | 242 | |||||||||||

| JMI15 | 25000 | 40000 | 1120 | 140,150 | 252 | 202 | 180 | 480 | 37.5 | forty seven.46×10four | 262 | four.8015 | |

| 160,one hundred seventy,180 | 302 | 242 | |||||||||||

| JMI16 | 40000 | 56000 | a thousand | one hundred sixty,a hundred and seventy,one hundred eighty | 302 | 242 | two hundred |

560 | 41 | forty eight.09×10four | 384 | nine.4118 | |

| one hundred ninety,two hundred | 352 | 282 | |||||||||||

| JMI17 | 63000 | 80000 | 900 | one hundred ninety,200,220 | 352 | 282 | 220 |

630 | forty seven | ten.13×10four | 561 | eighteen.3753 | |

| 240 | 410 | 330 | |||||||||||

| JMI18 | a hundred thousand | 125000 | 800 | 220 | 352 | 282 | 250 |

710 | 54.five | sixteen.14×104 | 723 | 28.2033 | |

| 240,250,260 | 410 | 330 | |||||||||||

| JMI19 | 160000 | 200000 | 710 | 250,260 | 410 | 330 | 280 | 800 | forty eight | seventy nine.8×10four | 1267 | 66.5813 | |

| 280,300,320 | 470 | 380 | |||||||||||

Item demonstrate: